Laser Dedicated Screw Air Compressor Technical parameters:

| Project | Parameters |

| Permanent magnet motor(2500rlmin) | 15KW/22KW |

| Main machine | 70A/80A |

| Cooling method | air cooling |

| Power condition | 380V/50Hz/3Ph |

| Average flow rate | 2.5m3 /min |

| Working pressure | 1.3MPA-1.5MPA |

| Noise | 65±2 |

| Insulation level | Level |

| Compressor | 1570x850x1620/1850x1100x1850 |

| Pressure dew point | 550/700 |

| Refrigerant type | WHPPO1800RCV |

| Size of the whole set(mm) | 2-10℃ |

| Weight of the whole set(kg) | R22 |

A laser dedicated screw air compressor is a type of air compressor that is specifically designed for use with laser cutting machines. These compressors are typically more powerful and efficient than standard air compressors, and they produce dry, oil-free air that is essential for laser cutting.

Laser dedicated screw air compressors typically have the following features:

· High air pressure: Laser cutting machines require high-pressure air, typically in the range of 100 to 150 psi.

· High air flow: Laser cutting machines also require a high volume of air, typically in the range of 10 to 20 CFM.

· Dry, oil-free air: Laser cutting machines are sensitive to moisture and oil, so the air compressor must produce dry, oil-free air.

· Noise reduction: Laser cutting machines can be noisy, so the air compressor should be as quiet as possible.

The cost of a laser dedicated screw air compressor varies depending on the size and features of the compressor. However, these compressors typically cost several thousand dollars.

If you are looking for an air compressor for use with a laser cutting machine, then a laser dedicated screw air compressor is a good option. These compressors can provide the high-pressure, dry, oil-free air that is essential for laser cutting.

When choosing a laser dedicated screw air compressor, it is important to consider the following factors:

· The size and power requirements of the laser cutting machine.

· The desired air pressure and flow rate.

· The noise level of the compressor.

· The budget.

It is also important to make sure that the compressor is from a reputable brand and that it comes with a warranty.

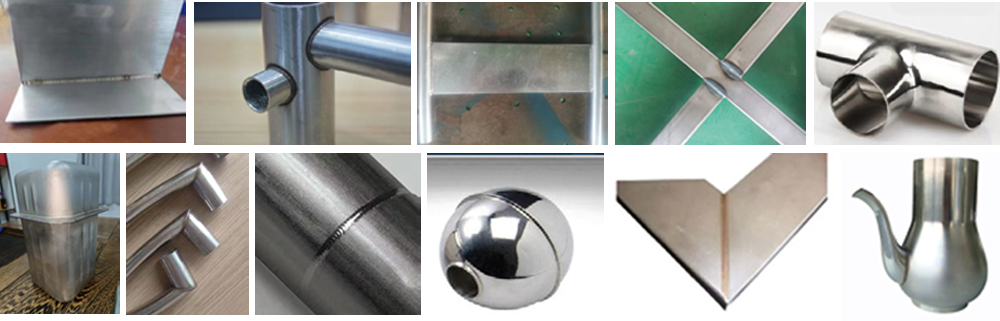

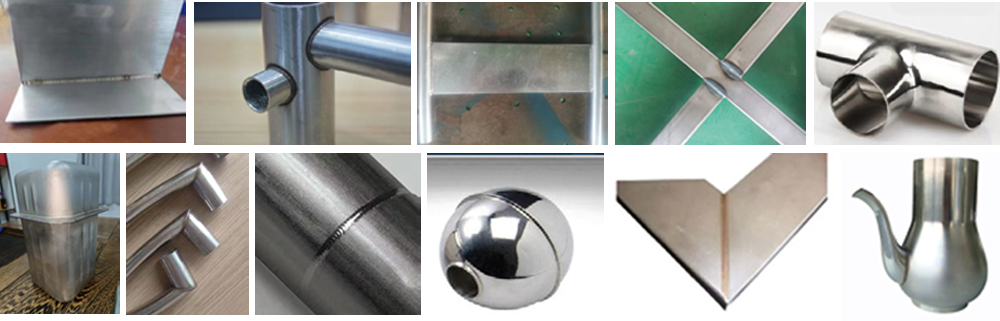

Cutting sample display

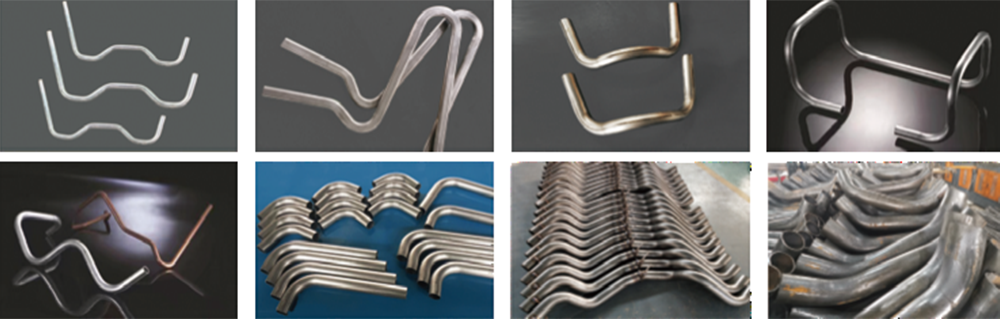

Welding sample display

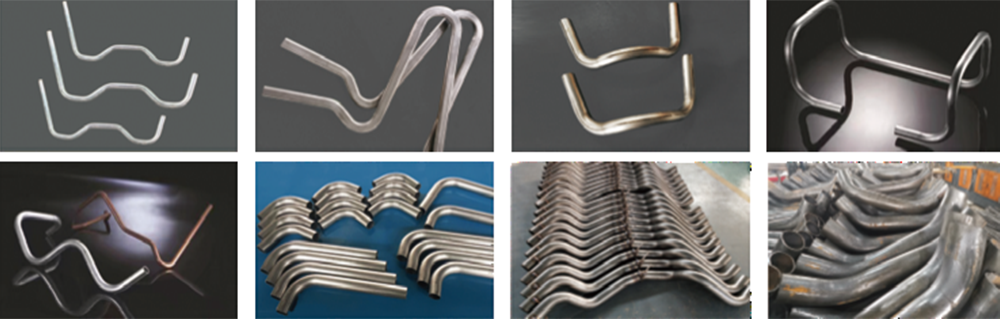

Processable pipe details

Service Support · QINGGONG Robot

Stricter quality control · Make quality better