Three-chucks Tube Laser Cutting Machine

Technical parameters

|

| Project | Parameters |

| Laser power | 1000W / 1500W / 2000W / 3000W /6000W |

| Chuck diameter | 120mm / 220mm / 350mm |

| Processing range | Φ10-120mm / Φ20-220mm / Φ30-350mm |

| Processing length | 6000mm |

| X / Y axis positioning accuracy | ±0.1mm |

| X / Y axis repeated positioning accuracy | ±0.1mm |

| Working voltage | 380V/50HZ |

| Power protection level | IP54 |

| Single pipe | 150kg / 300kg / 500kg |

| Tailings | 90-235mm / 90-235mm / 100-245mm |

A three-chucks tube laser cutting machine is a type of laser cutting machine that uses three chucks to hold the workpiece. The three chucks allow the workpiece to be rotated around its axis, which allows the laser beam to cut complex shapes and patterns.

The main components of a three-chucks tube laser cutting machine are:

· A laser source, typically a fiber laser.

· A beam delivery system, which focuses the laser beam onto the workpiece.

· Three chucks, which hold the workpiece.

· A CNC controller, which controls the movement of the laser beam and the chucks.

· A fume extraction system, which removes smoke and fumes from the cutting process.

Three-chucks tube laser cutting machines are used to cut a variety of materials, including steel, aluminum, copper, and plastics. They are used in a variety of industries, including manufacturing, aerospace, and medical.

The advantages of three-chucks tube laser cutting machines include:

· High speed: The laser beam can cut through material very quickly, making it a very efficient cutting method.

· High precision: The laser beam can be focused to a very small spot, resulting in high-precision cutting.

· Versatility: The machine can cut a wide variety of materials.

· Automated operation: The machine can be programmed to cut complex shapes and patterns automatically, freeing up operators for other tasks.

· Capability to cut tubes of different diameters and lengths.

The disadvantages of three-chucks tube laser cutting machines include:

· The initial cost of the machine is high.

· The machine requires regular maintenance.

· The machine can be dangerous if not operated properly.

If you are looking for a high-speed, precise, and versatile way to cut tubes, then a three-chucks tube laser cutting machine is a good option. These machines can save you time and money, and they can produce high-quality cuts that meet your requirements.

Here are some of the specific applications of three-chucks tube laser cutting machines:

· Cutting metal tubes for car parts, furniture, and machine tools.

· Cutting metal tubes for aircraft and spacecraft.

· Cutting plastic tubes for medical devices and packaging.

· Cutting glass tubes for mirrors and windows.

· Cutting pipe for plumbing and construction.

The cost of a three-chucks tube laser cutting machine varies depending on the size and features of the machine. However, the machines typically cost several hundred thousand dollars.

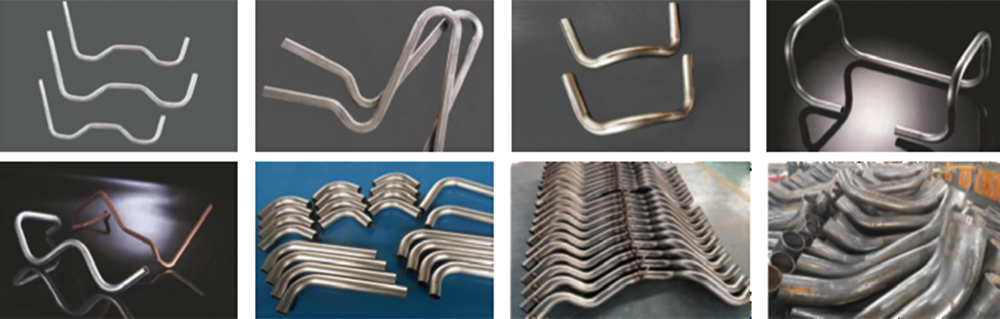

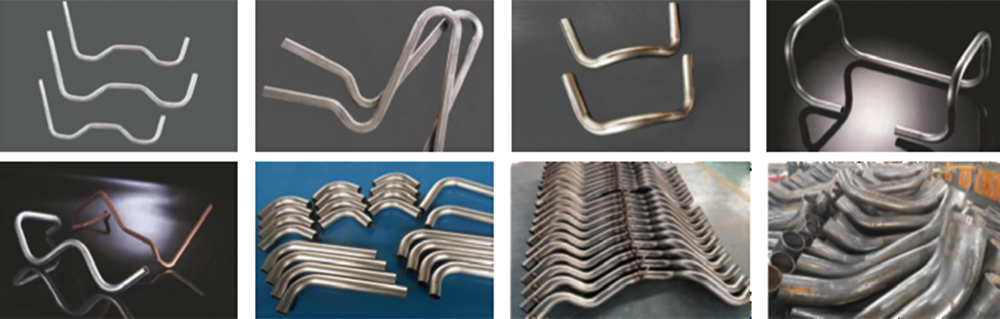

Processable pipe details

Service Support · QINGGONG Robot

Stricter quality control · Make quality better