The production process of artistic chandeliers is complex and involves multiple links. This article will combine the production process of artistic chandeliers to explore the application of laser pipe cutting machines, laser plate cutting machines, pipe bending machines and laser welding machines, and analyze their key role in improving the production process accuracy, efficiency and beauty.

1. Application of laser pipe cutting machines in artistic chandeliers

As an efficient and precise processing equipment, laser pipe cutting machines play a vital role in the production of artistic chandeliers. The lamp frame of the artistic chandelier is usually made of metal materials (such as stainless steel, aluminum alloy, etc.). The laser pipe cutting machine can accurately cut pipes of various shapes and sizes to provide stable support for the structure of the chandelier. The following are several key applications of the laser pipe cutting machine in the production of artistic chandeliers.

1.1 High-precision cutting

The laser pipe cutting machine uses a laser beam as a cutting tool. Compared with traditional mechanical cutting methods, its advantages are higher cutting accuracy, faster cutting speed and less prone to thermal deformation. The laser pipe cutting machine can accurately cut the pipe according to the design requirements. Whether it is straight cutting or curve cutting, it can ensure that the cutting surface is smooth and neat.

1.2 Cutting of various shapes

The laser pipe cutting machine can not only perform conventional cutting of straight pipes, but also cut various complex geometric shapes. For example, the cutting of circular, elliptical, triangular and other pipe ports, and even cutting at specific angles, can be efficiently completed by the laser pipe cutting machine.

1.3 Automation and efficient production

The laser pipe cutting machine has a high degree of automation and can automatically program cutting according to the design drawings. For some mass-produced art chandeliers, laser pipe cutting machines can greatly shorten the production cycle and improve overall production efficiency.

2. Application of laser plate cutting machines in art chandeliers

Similar to laser pipe cutting machines, laser plate cutting machines also play an extremely important role in the production process of art chandeliers. Laser plate cutting machines are mainly used to cut metal plates for chandeliers. Its high precision and high efficiency make the design and production of plates more flexible.

2.1 Accurate cutting of plates

Laser plate cutting machines can accurately cut plates of various shapes according to design drawings. The high-precision cutting of laser plate cutting machines can not only ensure that the size and shape of the plates fully meet the design requirements, but also avoid burrs and irregular edges caused by traditional cutting methods, thereby improving the aesthetics and craftsmanship of the finished products.

2.2 Cutting complex patterns and details

The design of modern art chandeliers is not limited to simple geometric shapes. Many complex designs require fine laser cutting. Laser plate cutting machines can accurately cut these patterns with their fine laser beams and high resolution, greatly improving the decorativeness and artistic sense of art chandeliers.

2.3 Minimize the heat affected zone

The laser plate cutting machine uses a high-precision laser beam to cut, and the heat affected zone is very small compared to traditional cutting methods. The laser plate cutting machine can effectively avoid material damage and ensure the quality of each piece of art.

3. Application of pipe bending machine and laser welding machine in art chandeliers

In addition to laser cutting equipment, pipe bending machine and laser welding machine are also important tools in the production process of art chandeliers. Pipe bending machine is mainly used for bending metal pipes, while laser welding machine is used for precision welding of metal parts.

The application of pipe bending machine and laser welding machine makes the complex structure and precision connection of art chandeliers more feasible.

3.1 Pipe bending machine: precise bending to create unique shapes

In the production of art chandeliers, pipe bending machine is mainly responsible for the bending of pipes. Pipe bending machine can achieve high-precision pipe bending, ensuring that the curvature and shape of each pipe fully meet the design requirements.

The advantage of pipe bending machine is that it has a high degree of automation, and can automatically adjust the bending parameters according to different pipe sizes and design requirements, and quickly complete bending of different shapes.

Through precise control, the pipe bending machine can not only ensure the quality of each pipe, but also greatly improve production efficiency.

3.2 Laser welding machine: efficient welding to ensure stable structure

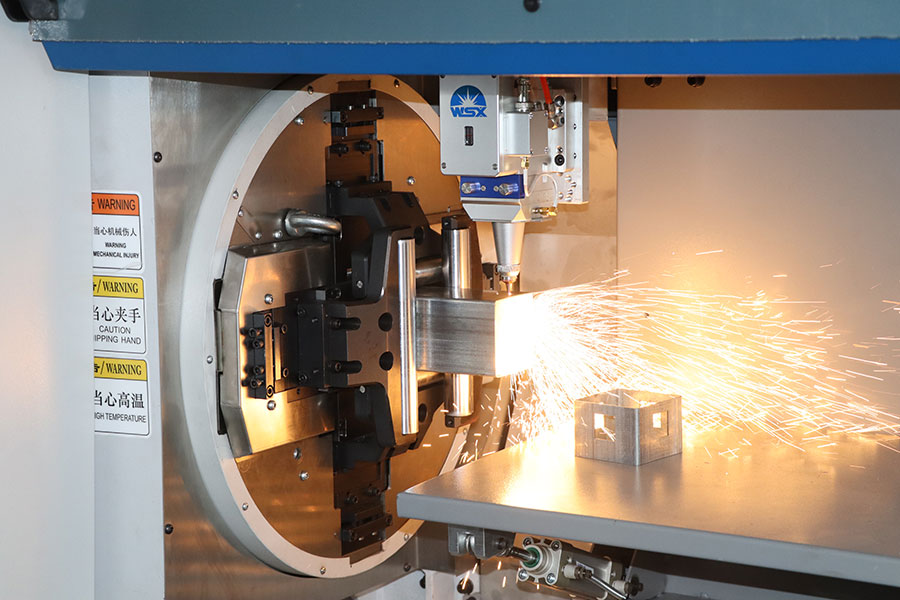

As a modern welding equipment, laser welding machine is widely used in the welding of metal parts.

The laser welding machine melts and connects metal parts together through a high-energy-density laser beam. The heat generated during the welding process is concentrated and precise, which can achieve miniaturization of the welding area and high-quality welding effects.

The main advantages of the laser welding machine are fast welding speed, fine welds and no thermal deformation, which are particularly suitable for artistic chandeliers with high requirements for beauty and precision.

Conclusion

The production of artistic chandeliers is a highly integrated innovation and technology process. The application of advanced equipment such as laser pipe cutting machines, laser plate cutting machines, pipe bending machines, and laser welding machines has improved the precision and efficiency of chandelier production, and also given designers more creative space.