As an important equipment in photographic equipment, the manufacturing process of professional tripods has extremely high requirements for stability, lightness and durability. Laser pipe cutting machines, laser plate cutting machines, pipe bending machines and laser welding machines play an important role in the manufacture of tripods, significantly improving production efficiency and product quality.

1. Application of laser pipe cutting machine in tripod pipe cutting

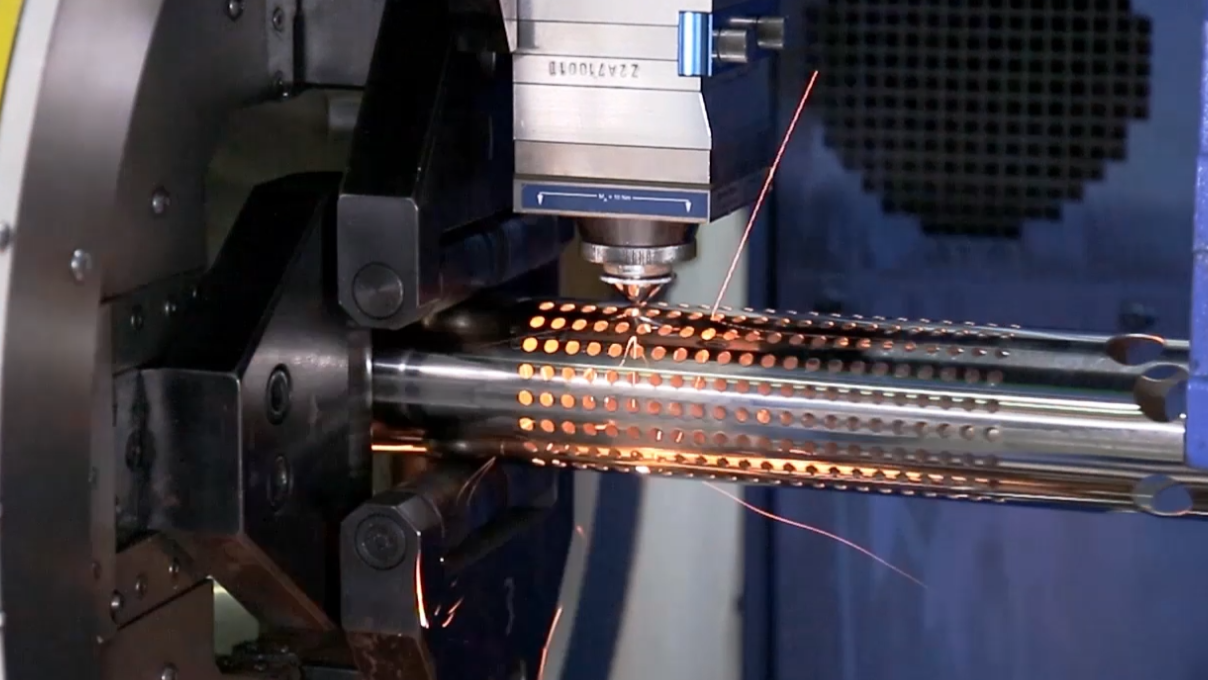

The leg pipes of professional tripods are usually made of aluminum alloy or carbon fiber pipes, and laser pipe cutting machines play an important role in this link.

1.1 High-precision cutting

The laser pipe cutting machine can cut the pipe with extremely high precision to ensure that the dimensions of each component of the tripod fully meet the design requirements. For example, when cutting aluminum alloy pipes, the laser pipe cutting machine can achieve an accuracy of ±0.1mm to ensure the assembly accuracy and overall strength of the leg pipes.

1.2 Complex shape processing

The design of tripods often includes a variety of complex shapes, such as bevels, holes, etc. Laser pipe cutting machines can quickly complete these complex cutting tasks through CNC programming, significantly improving production efficiency. For example, when cutting connectors, laser pipe cutting machines can accurately process beveled surfaces to ensure the tight fit of connectors.

1.3 Automated production

The laser pipe cutting machine is equipped with an automatic loading and unloading system, which can achieve continuous production, not only improving production efficiency, but also reducing production costs, making the manufacture of professional tripods more economical and efficient.

2. Application of laser plate cutting machine in the manufacture of tripod heads and accessories

The heads and accessories of tripods are usually made of high-strength metal sheets. Laser plate cutting machines have become the core equipment for the manufacture of these parts with their high precision and high efficiency.

2.1 Head cutting

Laser plate cutting machines can achieve fine cutting on materials such as aluminum alloys and stainless steel to ensure the perfect combination of the appearance and function of the head. For example, when cutting the gimbal, the laser plate cutting machine can accurately process complex shapes to ensure the stability and durability of the gimbal.

2.2 Accessory processing

The laser plate cutter can achieve micron-level precision cutting to ensure the performance and service life of the accessories.

2.3 Efficient production

The laser plate cutter supports mass production and quickly completes large-scale plate cutting through an automated system, significantly shortening the production cycle.

3. Application of pipe bending machine in tripod leg pipe bending

The leg pipe of the tripod needs to be bent and formed according to the design, and the pipe bending machine plays an important role in this process.

3.1 Precise bending

The pipe bending machine achieves precise bending through a CNC system to ensure that the angle and radius of the leg pipe meet the design requirements. For example, when manufacturing multi-section leg pipes, the pipe bending machine can achieve complex three-dimensional bending to ensure the stability and portability of the leg pipe.

3.2 Applicable to a variety of materials

The pipe bending machine is suitable for a variety of materials such as aluminum alloy pipes to meet the diverse needs of tripod manufacturing.

3.3 Efficient forming

The pipe bending machine is equipped with automatic feeding and clamping devices to achieve continuous bending operations and greatly improve production efficiency

4. Application of laser welding machine in the connection of key components of tripods

Laser welding machines are used to connect key components in tripod manufacturing, such as welding of leg pipes and pan heads, fixing accessories, etc.

4.1 High-precision welding

The laser welding machine achieves precise welding through high-energy laser beams, with narrow and deep welds and small heat-affected zones, ensuring welding strength and airtightness. For example, when welding leg pipes and pan heads, the laser welding machine can achieve leak-free welding to ensure the long-term and stable use of the tripod.

4.2 Welding of multiple materials

The laser welding machine is suitable for welding of multiple materials such as aluminum alloys to meet the connection requirements of different components in tripod manufacturing.

4.3 Automated welding

Large-volume laser welding machines can be equipped with robot automation systems to achieve efficient and continuous welding.

5. Conclusion

The application of laser pipe cutting machines, laser plate cutting machines, pipe bending machines and laser welding machines in the manufacture of professional tripods has not only improved production efficiency and product quality, but also promoted the overall technological progress of the photographic equipment industry. The comprehensive use of these equipment has set an example of high efficiency, precision and environmental protection for modern manufacturing.