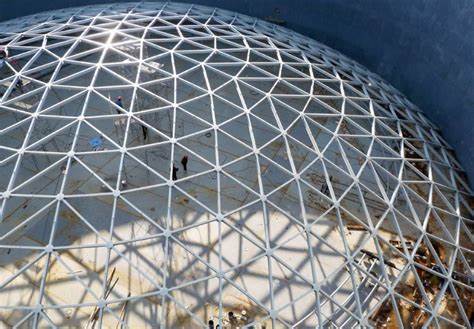

Space grid structures, which are widely used in modern architectural designs due to their lightweight yet strong characteristics, are one example where laser processing technologies like laser pipe cutting machines, laser plate cutting machines, pipe bending machines, and welding robots have proven to be highly effective.

1. Laser Pipe Cutting Machines: Precision in Steel Frame Production

The use of laser pipe cutting machines in the manufacturing of space grid structures has revolutionized the way steel components are produced. Laser pipe cutting machines, on the other hand, offer several advantages, making them indispensable in the modern construction industry.

High Precision and Customization

One of the key benefits of using laser cutting technology in pipe manufacturing is its ability to produce highly accurate and customized cuts.For space grid structures, where pipes are often joined at various angles and require precise lengths and hole placements, laser pipe cutting machine ensures that all components fit together seamlessly.

Efficiency and Speed

Laser pipe cutting machines are also known for their speed and efficiency. The use of laser pipe cutting machines can significantly enhance overall production efficiency.

Versatility in Cutting Shapes and Angles

Laser pipe cutting machines are capable of cutting pipes in a variety of shapes, including straight cuts, curved cuts, and holes. This versatility is essential in the manufacturing of space grid structures, where different components need to be interconnected at precise angles. With laser cutting technology, manufacturers can achieve a wide range of shapes and configurations, allowing for greater design flexibility and reducing the need for complex jigs or fixtures.

2. Laser Plate Cutting Machines: Enhancing Fabrication Accuracy

Laser plate cutting machines play a critical role in the production of steel plates used in the construction of space grid structures. In large steel structures, plates are often used as base components for beams, columns, and joints, and they need to be cut to specific dimensions to ensure proper fit and stability.

Precision Cutting of Steel Plates

Laser plate cutting machines offer unparalleled precision in the cutting of steel plates. They can cut intricate shapes and patterns with extremely tight tolerances, ensuring that each plate component aligns perfectly with the rest of the structure.

Flexibility in Material Types and Thicknesses

Laser plate cutting machines are versatile in terms of the materials they can handle. Whether it's mild steel, stainless steel, or aluminum, laser cutting can be applied to a wide range of materials commonly used in steel structure fabrication.

3. Pipe Bending Machines: Precision in Shaping Steel Pipes

Pipe bending machines, particularly those equipped with advanced laser technology, have transformed this process by offering greater precision and control.

Improved Accuracy and Consistency

Pipe bending machines enable manufacturers to bend pipes with exceptional accuracy and consistency. The pipe bending machine ensures that each bend is made at the correct angle and radius, reducing the likelihood of human error and ensuring that all pipes in the grid structure fit together seamlessly.

Reduced Material Waste

Another advantage of pipe bending machine is the reduction in material waste. This contributes to both cost savings and environmental sustainability, which are important considerations in large-scale construction projects.

Increased Production Speed

Pipe bending machines also offer faster processing times compared to traditional methods. As pipe bending machines can quickly and accurately execute multiple bends on a single piece of pipe, they can significantly reduce production time.

4. Welding Robots: Automation in the Assembly Process

Welding robots have become a key component in the manufacturing of large steel structure buildings, including space grid structures.Welding robots are capable of performing complex welding tasks with high repeatability, ensuring that the steel components are securely joined to form a stable and durable structure.

Consistency and Quality Control

One of the primary benefits of using welding robots is the consistency and quality of the welds. Welding robots operate with the same level of precision throughout the entire process.

Increased Speed and Productivity

Welding robots can perform tasks much faster than human welders, helping to speed up the assembly process. These welding robots are capable of working continuously without breaks, making welding robots an essential tool in the modern construction of space grid structures.

Safety and Ergonomics

Welding robots systems also improve workplace safety by reducing the need for human workers to be exposed to hazardous welding fumes, extreme heat, and other dangers associated with manual welding. And welding robots handle the physically demanding tasks.

Conclusion

Laser processing technologies, including laser pipe cutting machines, laser plate cutting machines, pipe bending machines, and welding robots, have significantly enhanced the manufacturing of large steel structure buildings, particularly in the case of space grid structures.