The manufacturing of turbine blades requires extremely high precision and material properties to ensure the reliability and efficiency of the engine under extreme conditions. Laser pipe cutting machines, laser plate cutting machines, pipe bending machines and laser welding machines play a vital role in the manufacturing process of turbine blades, significantly improving production efficiency and product quality.

1. Application of laser pipe cutting machines in the manufacturing of turbine blade cooling channels

1. High-precision cutting

The laser pipe cutting machine can cut the metal pipes used to manufacture cooling channels with extremely high precision to ensure that the size of the channel fully meets the design requirements. For example, when cutting nickel-based alloy pipes, the laser pipe cutting machine can achieve an accuracy of ±0.05mm to ensure the uniformity and efficiency of the cooling channel.

2. Complex shape processing

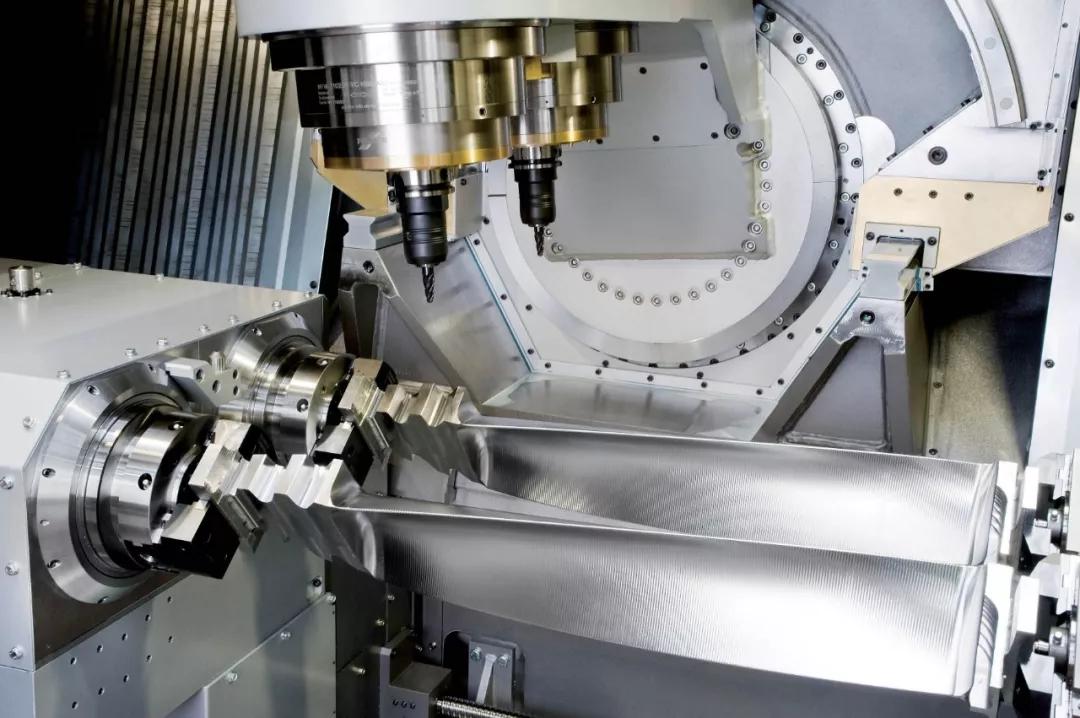

The laser pipe cutting machine can quickly complete the complex cutting tasks of the cooling channels of turbine blades through CNC programming, significantly improving production efficiency.

3. Automated production

The laser pipe cutting machine is equipped with an automatic loading and unloading system, which can achieve continuous production, reduce manual intervention, improve production efficiency and reduce error rates.

2. Application of laser plate cutting machine in the manufacture of turbine blade shell and connectors

The shell and connectors of turbine blades are usually made of high-strength metal sheets. Laser plate cutting machine has become the core equipment for the manufacture of these parts with its high precision and high efficiency.

1. Shell cutting

Laser plate cutting machine can achieve fine cutting on materials such as nickel-based alloys and titanium alloys to ensure the strength and sealing of the shell.

2. Connector processing

The connectors of turbine blades usually have complex shapes and size requirements. Laser plate cutting machine can achieve micron-level precision cutting to ensure the performance and service life of the connectors.

3. Efficient production

Laser plate cutting machine supports mass production and quickly completes large-scale plate cutting through automated systems, significantly shortening the production cycle.

3. Application of pipe bending machine in the manufacture of turbine blade cooling pipes

The cooling pipes of turbine blades need to be bent and formed according to the design, and pipe bending machine plays an important role in this process.

1. Precision bending

The pipe bending machine achieves precise bending through the CNC system to ensure that the angle and radius of the cooling pipe meet the design requirements. For example, when manufacturing cooling pipes, the pipe bending machine can achieve complex three-dimensional bending to ensure the stability and reliability of the cooling system.

2. Applicable to a variety of materials

The pipe bending machine is suitable for a variety of materials such as nickel-based alloy pipes and titanium alloy pipes to meet the diverse needs of turbine blade manufacturing.

3. Efficient forming

The pipe bending machine is equipped with automatic feeding and clamping devices to achieve continuous bending operations and greatly improve production efficiency.

4. Application of laser welding machines in the connection of key components of turbine blades

Laser welding machines are used to connect key components in turbine blade manufacturing, such as welding of blades to bases, sealing welding of cooling channels, etc.

1. High-precision welding

The laser welding machine achieves precise welding through a high-energy laser beam, with narrow and deep welds and a small heat-affected zone, ensuring welding strength and airtightness. For example, when welding blades to bases, the laser welding machine can achieve leak-free welding to ensure the long-term stable operation of turbine blades.

2. Welding of a variety of materials

The laser welding machine is suitable for the welding of a variety of materials such as nickel-based alloys and titanium alloys to meet the connection requirements of different components in turbine blade manufacturing.

3. Automated welding

Laser welding machines are equipped with automated systems to achieve efficient and continuous welding, reduce manual intervention, and improve production efficiency and consistency.

5. Future Outlook

With the rapid development of aerospace technology, laser processing technology will play a greater role in the manufacture of aircraft engines and other high-end aviation components. In the future, laser equipment will develop in the direction of higher precision, higher efficiency and more intelligence, bringing more innovation and breakthroughs to the aerospace manufacturing industry.

In short, the application of laser pipe cutting machines, laser plate cutting machines, pipe bending machines and laser welding machines in the manufacture of aircraft engine turbine blades has not only improved production efficiency and product quality, but also promoted the overall technological progress of the aerospace industry. The comprehensive use of these equipment has set an example of efficiency, precision and environmental protection for modern manufacturing.