As two important applications of laser technology, laser cutting machines and laser welding machines have gradually become indispensable equipment in modern manufacturing. However, the heat and chemical reactions generated during laser processing may have an adverse effect on the processing quality, so the use of shielding gas is particularly important. This article will introduce the working principle and application field of laser cutting machines and laser welding machines in detail, and explore the key role of shielding gas in laser processing.

1. Working principle and application of laser cutting machine

1.1 Working principle of laser cutting machine

Laser cutting machine is a device that uses a high-energy-density laser beam to cut materials. Laser cutting machines are usually composed of laser generators, optical systems, control systems, and cutting heads.

Laser cutting machines can be divided into CO2 laser cutting machines, fiber laser cutting machines, and YAG laser cutting machines according to different laser sources. Among them, CO2 laser cutting machines are suitable for cutting non-metallic materials, such as wood, plastics, and cloth; while fiber laser cutting machines and YAG laser cutting machines are more suitable for cutting metal materials, such as stainless steel, aluminum alloys, and titanium alloys.

1.2 Application fields of laser cutting machines

Laser cutting machines are widely used in many industries, mainly including the following aspects:

1. Metal processing industry: Laser cutting machines are most widely used in the metal processing industry, especially in the fields of automobile manufacturing, aerospace and electronic equipment manufacturing. For example, the cutting of automobile body parts, the processing of aircraft wings and the precision cutting of electronic components are all inseparable from laser cutting machines.

2. Non-metallic material processing: Laser cutting machines are also widely used in non-metallic material processing, such as cloth cutting in the clothing industry, acrylic plate cutting in the advertising industry and wood cutting in the furniture industry. The high precision and high efficiency of laser cutting machines have significantly improved the production efficiency of these industries.

3. Medical device manufacturing: Laser cutting machines are also increasingly used in medical device manufacturing. For example, the precision cutting and processing of surgical instruments, implants and medical equipment all require laser cutting machines.

1.3 The role of shielding gas in laser cutting

In the laser cutting process, the use of shielding gas is crucial. The shielding gas mainly has the following functions: preventing oxidation, blowing off slag and cooling.

2. Working principle and application of laser welding machine

2.1 Working principle of laser welding machine

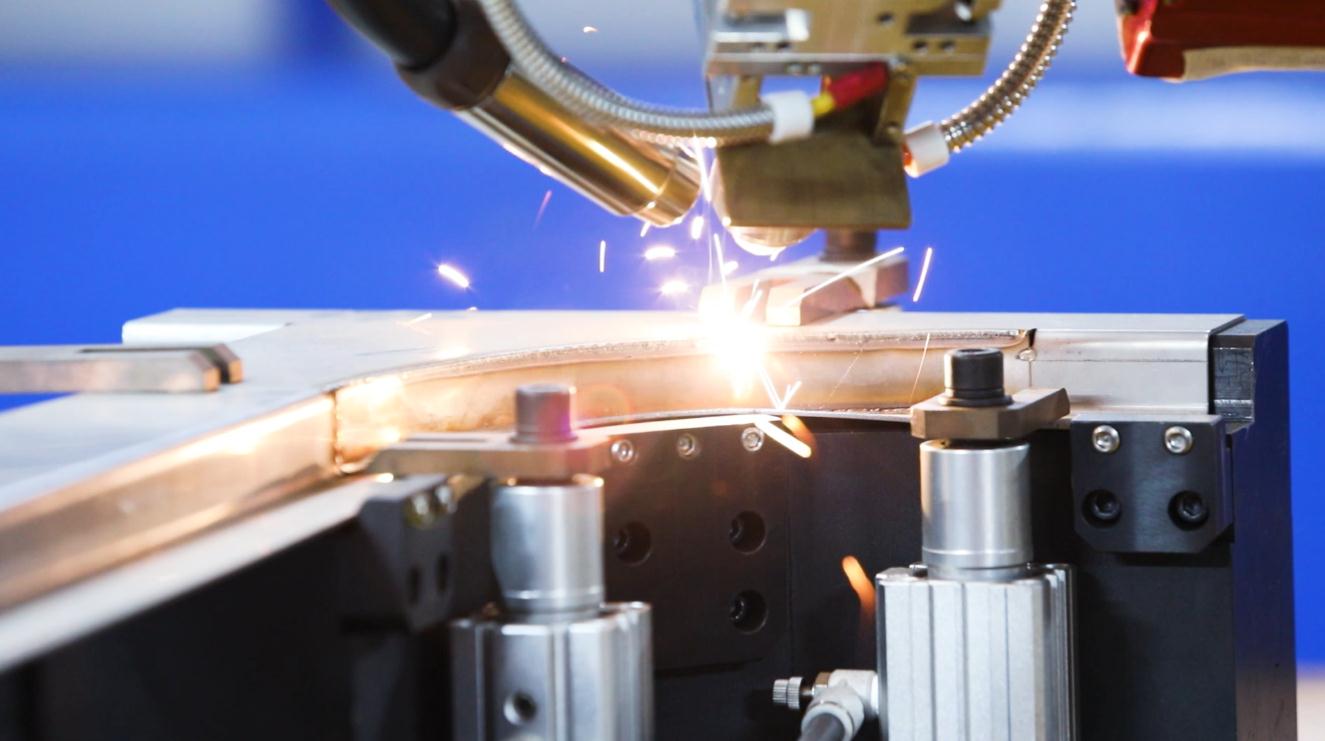

Laser welding machine is a device that uses a high-energy-density laser beam to weld materials. Laser welding machines are usually composed of laser generators, optical systems, control systems, and welding heads.

2.2 Application fields of laser welding machines

Laser welding machines are also widely used in multiple industries, mainly including the following aspects:

1. Automobile manufacturing industry: Laser welding machines are widely used in the automobile manufacturing industry, especially in the fields of body welding, engine component welding, and battery welding. For example, the welding of automobile bodies, engine cylinders, and electric vehicle batteries are all inseparable from laser welding machines.

2. Electronic equipment manufacturing: Laser welding machines are also widely used in electronic equipment manufacturing, especially in the welding of precision electronic components. For example, the welding of tiny components in electronic devices such as mobile phones and computers requires laser welding machines.

3. Medical device manufacturing: Laser welding machines are also increasingly used in medical device manufacturing. For example, the precision welding of surgical instruments, implants, and medical equipment requires laser welding machines.

2.3 The role of shielding gas in laser welding

In the process of laser welding, the use of shielding gas is also very important. Shielding gas has the following main functions: preventing oxidation, stabilizing the arc, and cooling.

3. Selection and optimization of shielding gas

3.1 Types of shielding gas

In the process of laser cutting and laser welding, the commonly used shielding gases are mainly the following:

1. Nitrogen (N2): Nitrogen is a commonly used shielding gas with good anti-oxidation properties. It is suitable for laser cutting and welding of materials such as stainless steel and aluminum alloys.

2. Argon (Ar): Argon is an inert gas with good anti-oxidation properties and the function of stabilizing the arc. It is suitable for laser welding of materials such as titanium alloys and nickel alloys.

3. Helium (He): Helium is also an inert gas with high thermal conductivity. It is suitable for high-power laser welding and can improve welding speed and welding quality.

4. Carbon dioxide (CO2): Carbon dioxide gas is also used in laser cutting, mainly for cutting carbon steel, which can improve cutting speed and cutting quality.

3.2 Optimization of shielding gas

In practical applications, the selection and optimization of shielding gas have an important impact on the quality of laser processing. Here are some suggestions for optimizing the use of shielding gas:

1. Select shielding gas according to material: Different materials have different requirements for shielding gas, and appropriate shielding gas should be selected according to the characteristics of the material. For example, stainless steel and aluminum alloys usually use nitrogen as shielding gas, while titanium alloys and nickel alloys are more suitable for argon or helium.

2. Control gas flow: The flow of shielding gas has an important influence on the quality of laser processing. If the flow is too small, it cannot effectively prevent oxidation and blow off slag; if the flow is too large, it may affect the focusing effect of the laser beam. Therefore, the gas flow should be reasonably controlled according to the processing requirements.

3. Optimize gas nozzle design: The design of gas nozzle has an important influence on the distribution and effect of shielding gas. Reasonable design of gas nozzle can make the shielding gas evenly distributed in the processing area and improve the protection effect.

Conclusion

As important equipment in modern manufacturing, laser cutting machines and laser welding machines have been widely used in many industries due to their high precision, high efficiency and high degree of automation. In the future, with the continuous advancement of laser technology and the continuous expansion of its application fields, laser cutting machines and laser welding machines will play an important role in more fields.