In modern manufacturing, the application of laser technology has gradually become an important means to improve production efficiency and precision. Especially in some industries with high precision requirements, the use of laser pipe cutting machines, laser plate cutting machines, pipe bending machines and laser welding machines has greatly promoted the advancement of manufacturing processes and improved product quality and production efficiency.

1. Application and advantages of laser pipe cutting machines

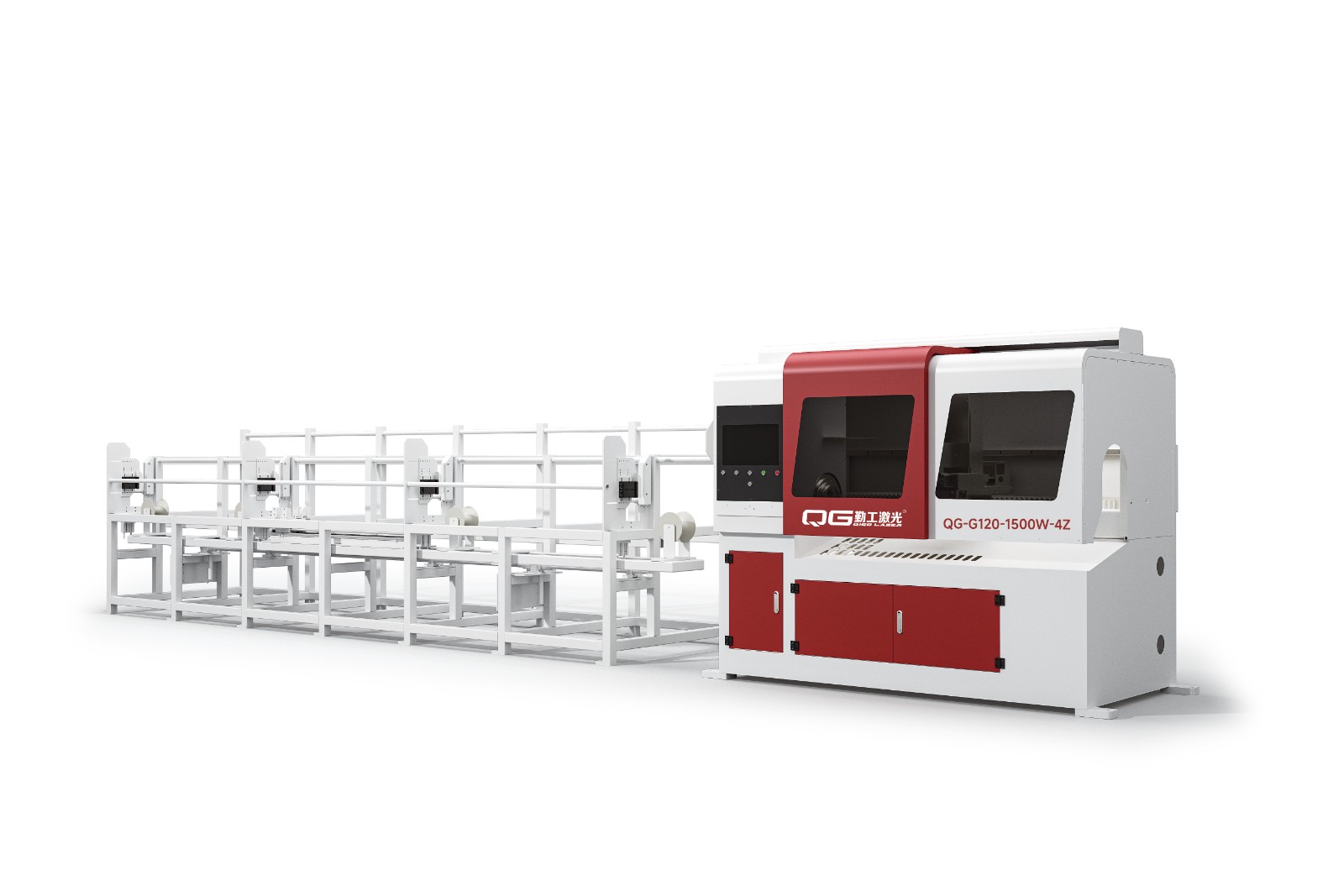

Laser pipe cutting machines are widely used in pipe processing, especially in the fields of automobiles, machinery, home appliances, etc., and have an irreplaceable and important position. Compared with traditional mechanical cutting, laser pipe cutting machines can achieve high-speed and precise cutting, and are suitable for various metal and non-metal materials, such as steel pipes, aluminum pipes, stainless steel pipes, etc.

1. 1High precision and high efficiency

One of the biggest advantages of laser pipe cutting machines is high precision. Traditional cutting methods often require multiple processes to achieve the ideal size and shape, while laser pipe cutting machines can directly irradiate the surface of the pipe with a laser beam to achieve fast and accurate cutting. Laser pipe cutting machines can effectively reduce material waste and improve production efficiency.

1.2 Flexibility and automation

The laser pipe cutting machine has a high degree of automation and can automatically adjust the cutting path and cutting speed according to different production needs to achieve the function of one machine for multiple uses. This makes the laser pipe cutting machine extremely flexible in the production line and can quickly switch between different processing tasks while ensuring quality.

1.3 Strong material adaptability

The laser pipe cutting machine can not only cut metal pipes, but also process other materials, such as plastic pipes, ceramic pipes, etc. In the production process that requires processing of multiple materials, the laser pipe cutting machine is undoubtedly an ideal equipment.

2. Advantages and applications of laser plate cutting machine

The laser plate cutting machine is a high-precision and high-efficiency equipment currently widely used in metal plate cutting and processing. It uses laser beam as a cutting tool and can achieve precise cutting of various metal materials through computer program control.

2.1 High-precision cutting

During the cutting process, the laser plate cutting machine can focus the laser on an extremely fine beam to ensure the accuracy of the cutting line. Especially in application scenarios with high requirements for small holes and high-precision cutting, the laser plate cutting machine can provide excellent cutting effects.

2.2 High-speed production

The laser plate cutting machine can complete large-area cutting work in a very short time. Compared with traditional mechanical cutting, the production efficiency of the laser plate cutting machine is greatly improved, especially in an environment where mass production is required, it can greatly shorten the production cycle and increase output.

2.3 No need for post-processing

The laser plate cutting machine has a smooth surface and neat edges after cutting, and basically no need for post-polishing and processing, which greatly improves production efficiency.

3. Application and advantages of pipe bending machines

Pipe bending machines play a vital role in modern manufacturing, especially when metal pipes with complex bending shapes need to be processed. Pipe bending machines can provide high-precision and high-efficiency processing solutions. It is widely used in construction, automobiles, home appliances, aerospace and other fields.

3.1 Efficient and precise bending processing

Pipe bending machines can achieve efficient bending of metal pipes through molds and hydraulic or electric drive systems. In some applications with extremely high bending accuracy requirements, pipe bending machines have become indispensable equipment.

3.2 Automation and multi-function

Modern pipe bending machines have a high degree of automation and can complete different bending tasks through computer programming control. The operator only needs to input the specific parameters of the pipe, and the pipe bending machine can automatically complete multiple processing processes such as cutting and bending of the pipe. In some automated production lines, the use of pipe bending machines has greatly improved production efficiency and processing accuracy.

3.3 Improve pipe utilization

Traditional pipe processing methods usually require a certain amount of pipe waste, while pipe bending machines can accurately control the bending angle, reduce material waste, improve pipe utilization, and reduce production costs.

4. Application and advantages of laser welding machine

is a device that uses high-energy laser beam as a heat source for metal connection. It has the advantages of high power, high energy density, and high welding quality. The use of laser welding machine can ensure the high precision, pollution-free, and contact-free characteristics of the welding process. It is widely used in automobile, aerospace, medical equipment, electronic equipment and other industries.

4.1 High-precision and high-quality welding effect

Laser welding machine can perform precise welding operations. Its laser beam has a very strong focusing ability and can accurately control extremely small welding points to ensure the accuracy of the welding gap.

4.2 High-speed production and automated operation

Laser welding machine is extremely fast during the welding process and can greatly improve production efficiency. In addition, the laser welding machine has a high degree of automation. Through the CNC system, it can accurately control parameters such as welding path and welding strength to achieve multi-variety and small batch production. For some complex welding needs, laser welding machine is undoubtedly an ideal choice.

4.3 Extremely small heat-affected zone

Due to the low heat input of laser welding machine, the heat-affected zone generated during welding is very small, which can effectively avoid deformation, oxidation and thermal damage of the welding part, and is particularly suitable for welding some precision components and thin-walled materials.

Conclusion

Laser pipe cutting machines, laser plate cutting machines, pipe bending machines and laser welding machines play an important role in the modern manufacturing process. They not only improve production efficiency and processing accuracy, but also help enterprises realize the automation and intelligence of the production process, injecting strong impetus into the development of the industry.