In industrial manufacturing, laser cutting machines are widely used in various industries due to their high efficiency and precision. However, due to the strong light radiation and flying sparks generated during laser cutting, operators face potential safety hazards. Therefore, laser cutting machine protective cover has become a key equipment to ensure safe operation. This article will discuss the role, type and how to choose a suitable protective cover of the laser cutting machine.

1. The role and significance of the protective cover

1.1 Protecting the safety of operators

The primary role of the laser cutting machine protective cover is to protect the safety of the operator. During the laser cutting process, the radiation generated by the laser beam may cause serious damage to the eyes and skin of the operator. The protective cover can effectively isolate harmful light and prevent it from directly contacting the operator to ensure its safety.

In addition, the sparks, slag and spatter generated during the cutting process also pose a potential threat to the operator. The protective cover can not only block these spatters, but also reduce the probability of accidents caused by improper operation.

1.2 Improve production efficiency

Operating the laser cutting machine in a closed and controlled environment can avoid external interference, such as dust and other impurities affecting the cutting accuracy. At the same time, the protective cover can effectively isolate external noise, reduce interference with other workers or equipment, and provide a quiet working environment. In this way, the laser cutting machine can continue to work in an efficient and safe state, thereby improving overall production efficiency.

2. Types of laser cutting machine protective covers

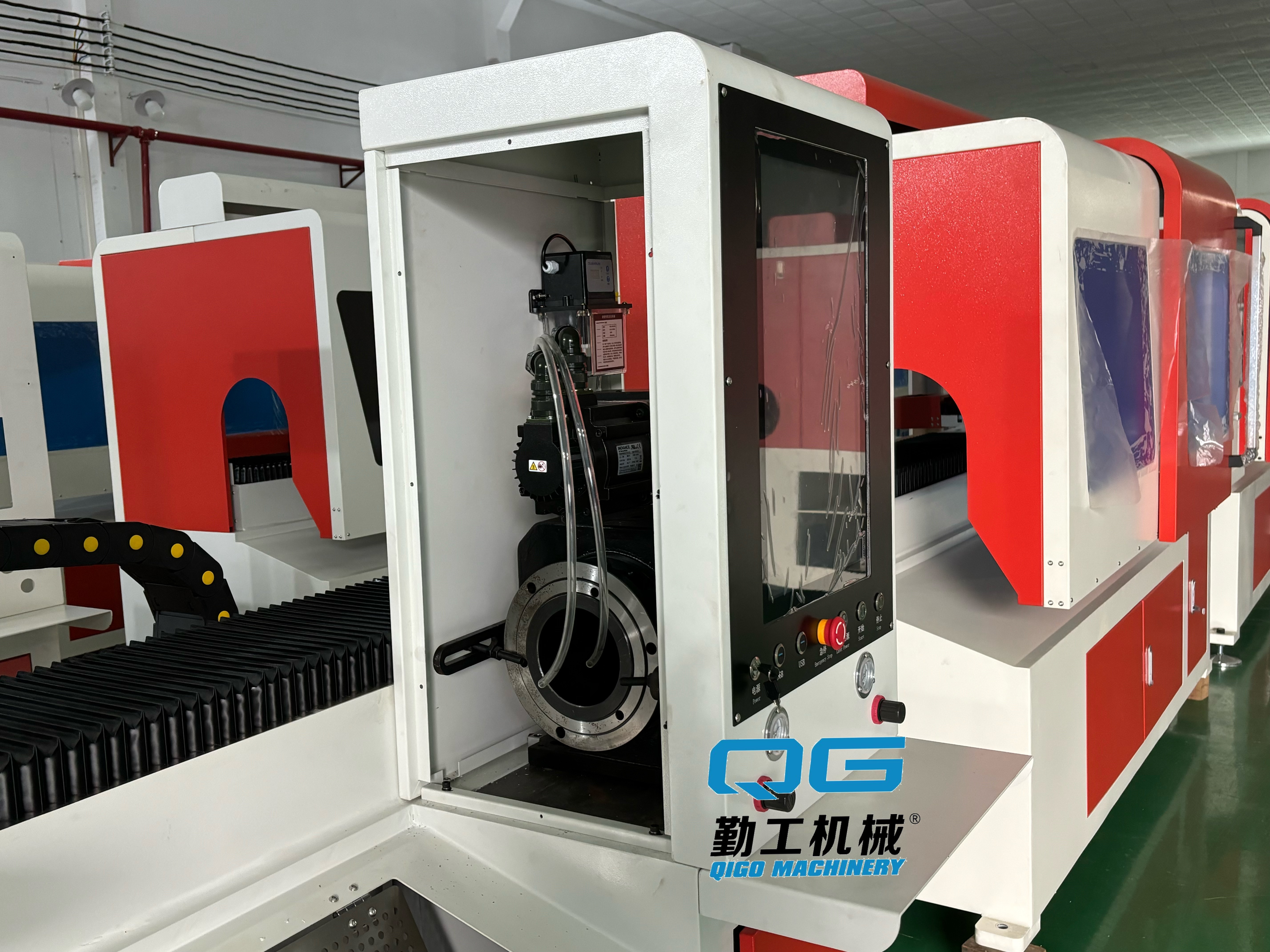

2.1 Fixed protective covers

Fixed protective covers are usually used for large laser cutting equipment, which can cover the entire cutting area. Operators can observe the cutting process in real time through monitoring equipment without approaching the cutting area, thereby ensuring safety.

In addition, fixed protective covers are usually equipped with ventilation and filtration systems, which can effectively handle the smoke and harmful gases generated during the cutting process. The design of this type of protective cover is suitable for large factories and automated production lines, and is characterized by high efficiency, safety, and high degree of automation.

2.2 Movable protective covers

Compared with fixed protective covers, movable protective covers have greater flexibility and are suitable for small and medium-sized laser cutting equipment. This type of protective cover can be freely moved and adjusted as needed, and is suitable for various irregular workplaces.

Movable protective covers are usually made of lightweight materials, which are easy to disassemble and transport, and are widely used in temporary working environments or work scenes that require frequent relocation.

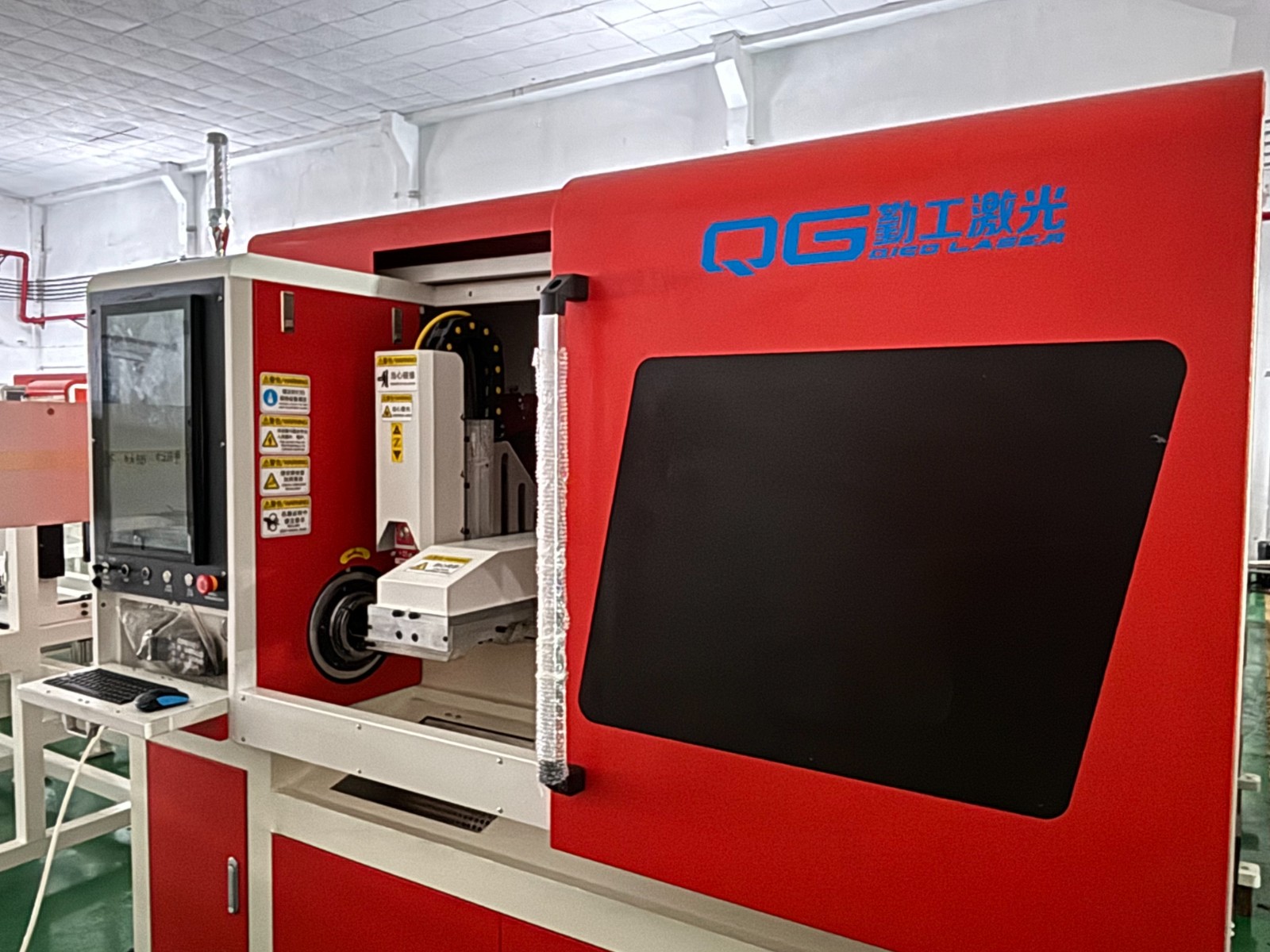

2.3 Automatic opening and closing protective cover

The automatic opening and closing protective cover is an intelligent design. When the laser cutting machine is started, the protective cover automatically closes and seals the operating area; when the cutting is completed, the protective cover automatically opens to facilitate the operator to carry out subsequent processing.

This design not only improves the convenience of operation, but also greatly reduces the safety hazards caused by human negligence. It is suitable for modern production workshops with high requirements for automation and safety.

3. How to choose a suitable laser cutting machine protective cover

3.1 Choose according to equipment model and cutting power

When choosing a laser cutting machine protective cover, the first thing to consider is the model and power of the cutting equipment. Different models of laser cutting machines need to match different protective covers.

For example, for high-power laser cutting machines, the protective cover must be able to withstand high-intensity laser radiation and a large number of sparks generated during the cutting process, so a protective cover with higher material strength needs to be selected. For small laser cutting machines, a lightweight protective cover can be selected for easy operation and movement.

3.2 Consider the workplace and working environment

The working environment is also a factor that needs to be considered when choosing a protective cover. If the workplace is large and the operating location needs to be changed frequently, a movable protective cover is obviously more suitable. For fixed production lines or large factory workshops, fixed protective covers can provide higher safety and stability.

In addition, if there is a lot of dust and smoke in the working environment, it is necessary to choose protective covers equipped with ventilation and filtration systems to ensure the cleanliness and safety of the operating environment.

3.3 Safety certification and product quality

The quality of the laser cutting machine protective cover is directly related to the safety of the operator. Therefore, when choosing a protective cover, products that have passed national or industry safety certification must be given priority. This type of certification not only ensures that the material and design of the protective cover meet the standards, but also guarantees its safety performance in extreme environments.

In addition, choosing well-known brands or products that have been tested in the market can also improve the safety of use. Although high-quality protective covers may be expensive, in the long run, their durability and reliability can effectively reduce replacement costs and the occurrence of safety accidents.

Conclusion

In short, when choosing a protective cover, it is necessary to comprehensively consider factors such as equipment model, working environment, and safety certification to ensure that safety and efficiency are given equal importance. In modern industrial production, choosing a suitable laser cutting machine protective cover is not only a protection for production equipment, but also a guarantee for the life safety of operators.