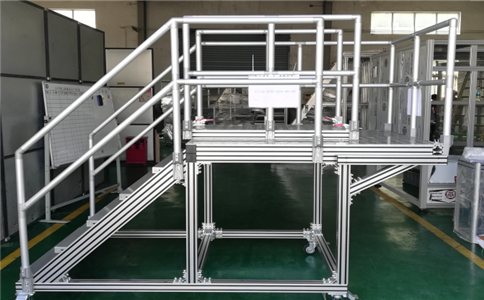

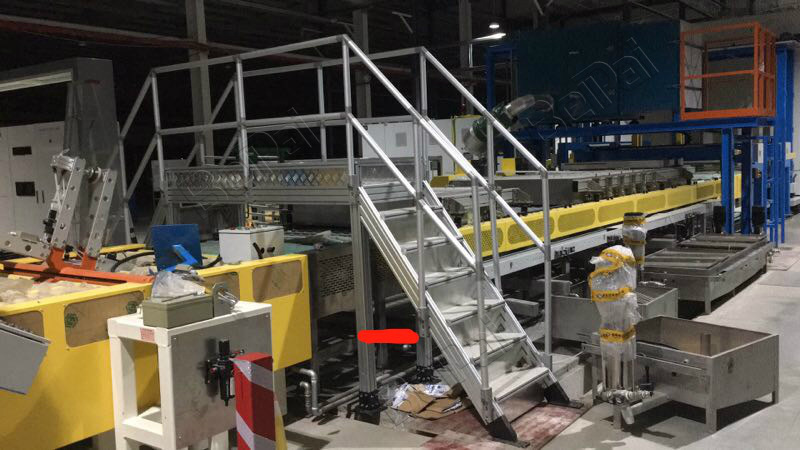

As a common access structure in modern buildings and industrial facilities, metal stepping platforms are widely used in industrial platforms, stairs, scaffolding and other occasions. This article will introduce the production process of metal stepping platforms in detail, focusing on the application of laser plate cutting machines, laser pipe cutting machines, pipe bending machines and laser welding machines in the entire production process, and how they improve the production efficiency, precision and quality of metal stepping platforms.

1. Overview of the production process of metal step platforms

The production of metal step platforms involves multiple process steps, from design, material selection to processing, welding and assembly, each link requires high-precision operation and the support of advanced equipment.

2. Application of laser plate cutting machine in the production of metal step platforms

2.1 Working principle of laser plate cutting machine

The laser plate cutting machine uses laser beam as a cutting tool, and uses the high temperature of the laser beam to melt and evaporate the metal, and finally achieves the cutting effect.

2.2 Advantages of laser plate cutting machine

The application of laser plate cutting machine in the production of metal step platforms is mainly reflected in the following aspects:

·High-precision cutting: Laser cutting technology can achieve extremely high cutting accuracy, and the error is usually controlled within 0.1mm. The laser plate cutting machine can provide precise cutting edges to ensure perfect docking of various components.

·Cutting of complex shapes: The laser plate cutting machine can flexibly cut various complex shapes according to the design drawings, such as irregular holes, edge cutting, etc., to meet complex design requirements.

· Material saving: The cutting width of the laser plate cutting machine is very narrow, which can greatly reduce material waste and save costs compared with traditional cutting methods.

· Automated operation: Modern laser plate cutting machines are usually equipped with CNC systems, which can automatically complete cutting according to design documents, reduce manual operations and improve production efficiency.

2.3 Application of laser plate cutting machines in metal stepping platforms

In the production process of metal stepping platforms, laser plate cutting machines are usually used in the following aspects:

· Tread cutting: The laser plate cutting machine can complete the cutting task quickly and accurately to ensure the size and shape of the tread.

· Support platform and connector cutting: The cutting of support platforms and various connectors is also one of the main applications of laser plate cutting machines. The laser plate cutting machine can accurately cut various shapes of connecting plates according to the design drawings to ensure the stability of the structure.

3. Application of laser pipe cutting machine and pipe bending machine in the production of metal stepping platforms

3.1 Working principle of laser pipe cutting machine

Laser pipe cutting machine uses laser beam to cut metal pipes. Its working principle is similar to that of a laser plate cutter. It uses a high-energy laser beam to heat the surface of the tube to the melting point and work with the gas to quickly remove the molten metal and complete precise cutting.

3.2 Advantages of laser pipe cutting machines

The advantages of laser pipe cutting machines in the production of metal stepping platforms are mainly reflected in:

·Precise cutting: The laser pipe cutting machine can provide extremely high cutting accuracy, especially suitable for cutting tasks of complex tubes.

·High efficiency: The laser pipe cutting machine has a fast cutting speed, which is particularly suitable for mass production and can significantly improve production efficiency.

·High degree of automation: Laser pipe cutting machines are usually equipped with CNC systems, which can realize automated operation, reduce manual intervention, and improve production efficiency and accuracy.

3.3 Working principle and advantages of pipe bending machines

Pipe bending machines are mainly used for bending metal tubes. Through mechanical force or hydraulic pressure, pipe bending machines can bend tubes into the desired angle or curve. The working principle of the pipe bending machine is to use mechanical force to fix the tube and bend it through rollers or molds.

The advantages of pipe bending machines include:

· Efficient bending: pipe bending machines can quickly and accurately bend pipes, especially for complex structural parts such as handrails and support columns.

· Reduce welding points: Through the processing of pipe bending machines, pipes can be bent directly to the required angle, reducing the parts that need to be welded and improving the stability and strength of the structure.

4. Application of laser pipe cutting machines and pipe bending machines in metal stepping platforms

In the production of metal stepping platforms, laser pipe cutting machines and pipe bending machines are mainly used for:

· Cutting and bending of supporting structure pipes: laser pipe cutting machines can accurately cut pipes to meet complex design requirements; pipe bending machines can bend pipes according to design requirements to form the required angles and curves.

· Handrail bending: The handrail part needs to be bent to meet ergonomic design, and the pipe bending machine can complete this task quickly and accurately.

5. Application of laser welding machines in the production of metal stepping platforms

5.1Working principle of laser welding machines

Laser welding machines heat metal to the melting point through high-energy laser beams and use the powerful energy of the beam to achieve the welding process.

5.2 Advantages of laser welding machine

Laser welding machine has the following advantages:

·High precision: Laser welding machine can achieve high-precision welding, especially suitable for welding thin plates or small parts.

·Fast welding speed: The welding speed of laser welding machine is faster than traditional welding methods, suitable for mass production.

·Low heat-affected zone: The heat-affected zone of laser welding machine is small, which can ensure the welding quality of metal stepping platform.

5.3 Application of laser welding machine in metal stepping platform

The main applications of laser welding machine in metal stepping platform include:

·Welding of pipes and plates: Laser welding machine can achieve precise welding between pipes and plates, ensuring welding quality and connection firmness.

·Welding of complex parts: Laser welding machine can accurately weld complex parts to ensure the stability of the structure.

6.Summary

Laser plate cutting machine, laser pipe cutting machine, pipe bending machine and laser welding machine play an extremely important role in the production of metal stepping platform. They not only improve the efficiency and precision of the production process, but also ensure the high standards of strength, stability and aesthetics of metal stepping platform.