In the manufacturing process of child safety gates, the application of various processes and equipment is involved, especially some advanced mechanical equipment such as laser pipe cutting machines, pipe bending machines, laser welding machines, etc., which greatly improve production efficiency and product accuracy.

1. Design and manufacturing requirements of child safety gates

The design of child safety gates not only requires beauty, simplicity, and conformity to the home environment, but also needs to ensure the safety and stability of its structure.

2. Application of key equipment in the manufacture of child safety gates

In the manufacturing process of child safety gates, the use of equipment such as laser pipe cutting machines, pipe bending machines, and laser welding machines can greatly improve production efficiency and product accuracy, ensuring that the quality and appearance of the gates meet the requirements.

2.1 Application of laser pipe cutting machines

As a high-precision cutting equipment, laser pipe cutting machines are widely used in the processing of metal pipes. In the production of child safety gates, the application of laser pipe cutting machines can bring the following significant advantages:

High-precision cutting: Laser pipe cutting machines can achieve high-precision cutting, ensuring that the cutting line of the pipe is straight and smooth, without the need for subsequent processing. For products such as child safety gates that have strict dimensional requirements, the accuracy of laser pipe cutting machines is crucial.

Flexibility: Laser pipe cutting machines support cutting of a variety of complex shapes, including round, square, special-shaped, etc.

Improve production efficiency: The cutting speed of laser pipe cutting machines is fast, which can greatly improve production efficiency and shorten production cycles. At the same time, no mechanical pressure is generated during laser cutting, reducing the possibility of material deformation.

Save materials: Laser pipe cutting machines has a smaller cutting gap, which can minimize material waste and reduce production costs.

In the manufacture of child safety gates, laser pipe cutting machines can not only ensure cutting accuracy and speed, but also avoid waste through precision cutting, thereby improving overall production efficiency.

2.2 Application of pipe bending machines

The frame of child safety gates is generally composed of bent metal pipes, and the use of pipe bending machines has become an indispensable part of this process. Pipe bending machines can accurately bend metal pipes according to design requirements to ensure the stability and aesthetics of the gate structure. The main advantages of pipe bending machines include:

Precise control: Modern pipe bending machines are equipped with CNC systems, which can accurately control parameters such as bending angles and radii to ensure that the bending angles and shapes of each pipe meet the design requirements and ensure the overall stability of the safety gate structure.

High efficiency: Modern CNC pipe bending machines can not only greatly improve the efficiency of pipe bending, but also realize automated operation in mass production, greatly shortening production time.

Reduce material loss: When using pipe bending machines for production, it can reduce the deformation and loss of pipes, ensure that the materials of the gates can be fully utilized, and reduce production costs.

By bending the pipe with a pipe bender, manufacturers can produce safety gate frames that meet the design requirements and improve the structural stability and durability of the product.

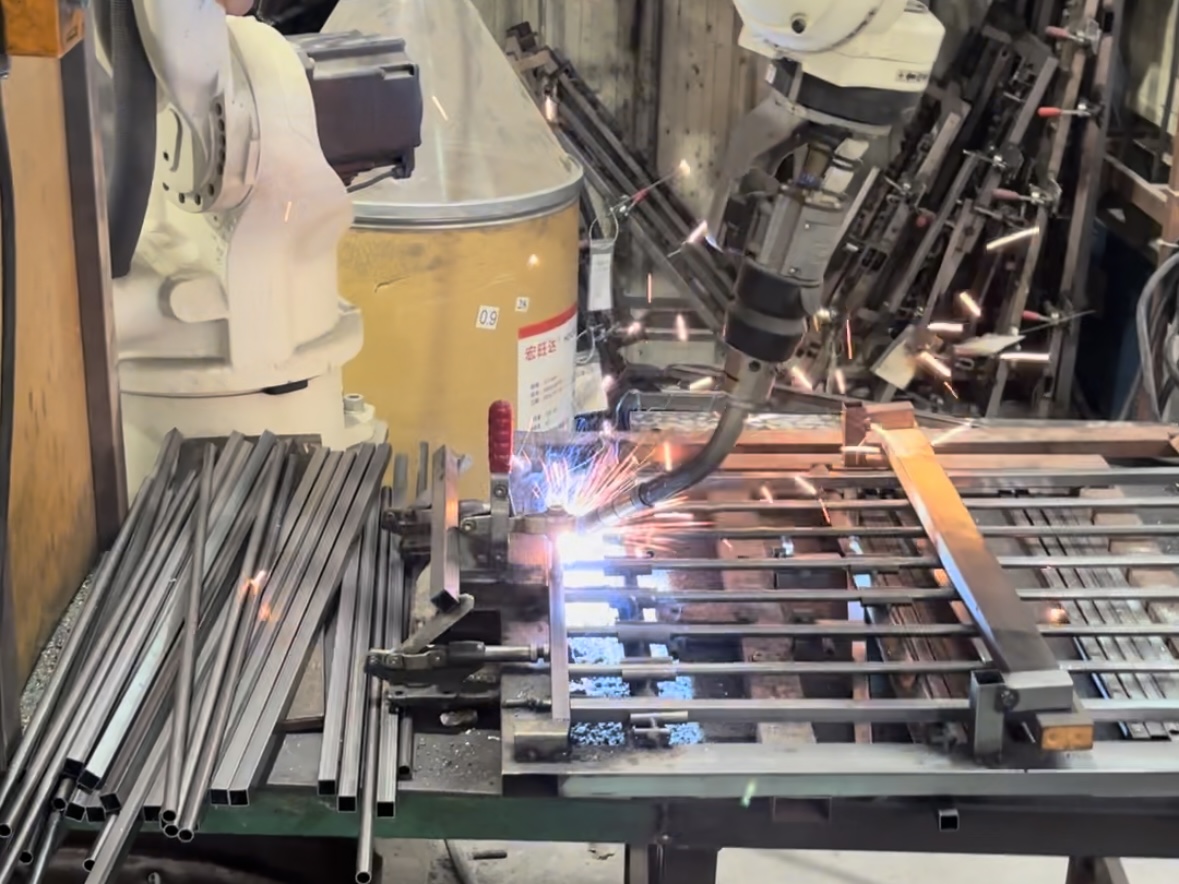

2.3 Application of laser welding machine

In the manufacturing process of child safety gates, laser welding is a key step to connect the various components together.

Fine welding: The laser welding machine can achieve high-precision and high-strength welding effects by precisely positioning the laser beam for welding. For products such as child safety gates that require high welding quality, laser welding provides more reliable technical support.

Increase welding speed: The laser welding machine has a high welding speed, which can greatly improve production efficiency and shorten production cycles. At the same time, no thermal deformation will occur during laser welding, ensuring the accuracy and stability of the gate frame.

Reduce post-processing work: laser welding machines can effectively reduce weld defects, reduce later cleaning and trimming work, and further improve production efficiency.

Improve safety: laser welding machine uses a non-contact heating method, and no obvious sparks or droplets will be generated during welding, reducing the safety risks of operators.

The application of laser welding machines makes the welding part of child safety gates more refined and solid, ensuring the overall quality of the product.

III. Conclusion

The manufacturing of child safety gates involves multiple links, among which the application of advanced equipment such as laser pipe cutting machines, pipe bending machines, and laser welding machines greatly improves production efficiency and product quality. With the continuous development and innovation of technology, the manufacturing of child safety gates will become more and more refined and intelligent, and the safety and aesthetics of the products will continue to improve.