The production process of canteen tables and chairs involves the processing of raw materials to the assembly of finished products, and many of these links rely on the support of advanced equipment such as laser cutting and laser welding. This article will focus on the production process of canteen tables and chairs, and explore the application of laser pipe cutting machines, laser plate cutting machines, pipe bending machines and laser welding machines in them.

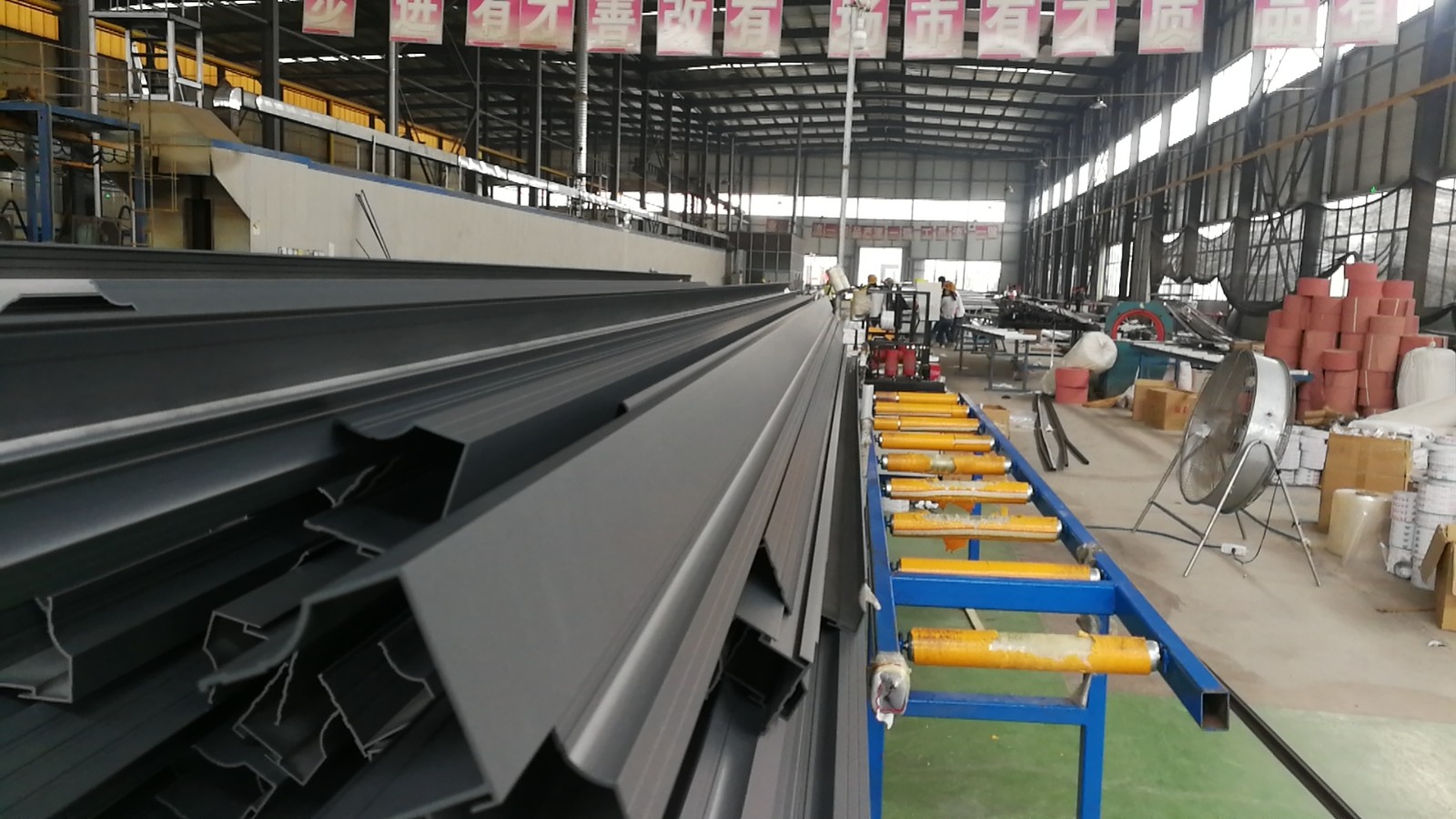

1. Raw material preparation: selection and processing of metal sheets and pipes

The main structural parts of canteen tables and chairs usually use metal materials, such as stainless steel, carbon steel or aluminum alloy.

During the production process, it is first necessary to select suitable metal sheets and pipes according to the design drawings. Then use technologies such as laser cutting machines, pipe bending machines and laser welding machines to process the raw materials into parts that meet the design requirements.

2. Laser cutting: high-precision processing of parts

In the process of making canteen tables and chairs, laser cutting technology is usually used to cut metal plates and pipes.

2.1 Application of laser plate cutting machine

Laser plate cutting machine is a kind of equipment used for cutting metal plates. For the production of canteen tables and chairs, laser plate cutting machine can accurately cut various parts according to the design drawings, such as tabletops, chair seats and other plate parts.

After the laser beam is focused by the high-energy laser emitter of the laser plate cutting machine, it directly acts on the surface of the metal plate, melts and evaporates the metal locally through the instantaneous high temperature, and then blows away the cut slag through the gas injection system.

The high precision of the laser plate cutting machine enables the size of the parts to be strictly controlled, and the edges of the cut metal are smooth and flat, which meets the requirements of subsequent processing and assembly.

The laser cutting machine can not only greatly improve the cutting efficiency, but also effectively reduce manual errors, ensuring the quality and beauty of the dining table and chairs.

2.2 Application of laser pipe cutting machine

The laser pipe cutting machine can cut metal pipes into different lengths and shapes according to different design requirements.

The working principle of the laser pipe cutting machine is similar to that of the laser plate cutting machine, but it is specially used for cutting pipes. Laser pipe cutting machines can achieve multi-angle cutting, hole opening, and complex contour engraving of pipes.

2.3 Cutting effect

Laser cutting machines have very high cutting accuracy, and the dimensional error of the cut pipes and plates can be controlled at the millimeter or even sub-millimeter level.

3. pipe bending process: pipe forming and design

Bending metal pipes into the required shape through a pipe bending machine can make the overall structure of the dining table and chairs more in line with the design requirements, and can improve the stability and aesthetics of the furniture.

3.1 Use of pipe bending machine

A pipe bending machine is a device specially used for bending metal pipes. It can achieve different angles and different radii of pipes. The working principle of the pipe bending machine is mainly to pull the pipe into the mold through the role of the mold, and use high pressure or rollers to bend the pipe into a specified shape.

The pipe bending machine is usually equipped with a CNC system, which can accurately control each bending angle and radius, so that the bent pipe meets the design requirements.

Common pipe bending methods include push bending, rolling bending and extrusion bending. According to different design requirements, different bending methods can be selected to achieve the ideal effect.

For the leg brackets of the canteen tables and chairs, the pipe bending machine can make the pipes better fit the ergonomic design, increase comfort and stability.

4. Laser welding: precise connection and high-strength fixation

In the production process of canteen tables and chairs, laser welding machines are mainly used to connect the various parts of the tables and chairs to ensure the firmness and durability of the structure.

4.1 Application of laser welding machine

The laser welding machine uses a high-energy laser beam to locally heat the workpiece to a molten state to form a weld, thereby tightly connecting the two metal parts.

The advantages of the laser welding machine are its high precision and low heat-affected zone, which can ensure that the metal at the weld does not undergo excessive thermal deformation, thereby ensuring the overall structural stability of the dining table and chair.

In addition, the laser welding machine can also reduce the cleaning work after welding, and the welding marks are delicate and smooth, and almost no polishing is required.

During the welding process, the laser welding machine uses a precise laser control system to accurately focus the laser beam on the welding part. After the welding is completed, the metal at the weld will cool rapidly to form a solid connection.

Conclusion

With the continuous advancement of manufacturing technology, the application of laser pipe cutting machines, laser plate cutting machines, pipe bending machines and laser welding machines in the production process of canteen tables and chairs has greatly improved production efficiency and product quality. In the future, with the continuous innovation of technology, the production of tables and chairs will be more intelligent and efficient, bringing more convenience and comfort to people's daily life.