With the advancement of manufacturing technology, modern equipment such as laser pipe cutting machine, laser plate cutting machine, laser welding machine, pipe bending machine, etc. have been widely used in the production of farm carts. This article will focus on the role of various machines and equipment in production.

1. Laser pipe cutting machine: precise cutting of frame pipes

Laser pipe cutting machine is a commonly used pipe cutting equipment in modern manufacturing industry, which uses high-power laser beam to accurately cut metal pipes. Cutting with laser pipe cutting machine can not only ensure cutting accuracy, but also effectively reduce the waste generated during cutting.

The advantages of laser pipe cutting machine are its high efficiency, precision and high degree of automation. Compared with traditional mechanical cutting, laser pipe cutting machine can complete complex cutting tasks in a shorter time, and the cutting edge is smooth and does not require secondary processing.

In addition, the CNC system of the laser pipe cutting machine can be directly programmed according to the design drawings, avoiding errors in manual operation.

Application examples of laser pipe cutting machines

In the process of making the frame of agricultural carts, laser pipe cutting machines are mainly used to accurately cut pipes. For example, the connecting part of the frame usually needs to be cut at 45 degrees or 90 degrees, and the laser pipe cutting machine can accurately control the cutting angle through the CNC program to ensure the accuracy and consistency of the cutting. At the same time, the laser pipe cutting machine can also achieve multiple cutting of different pipes to meet the needs of various frame structure designs.

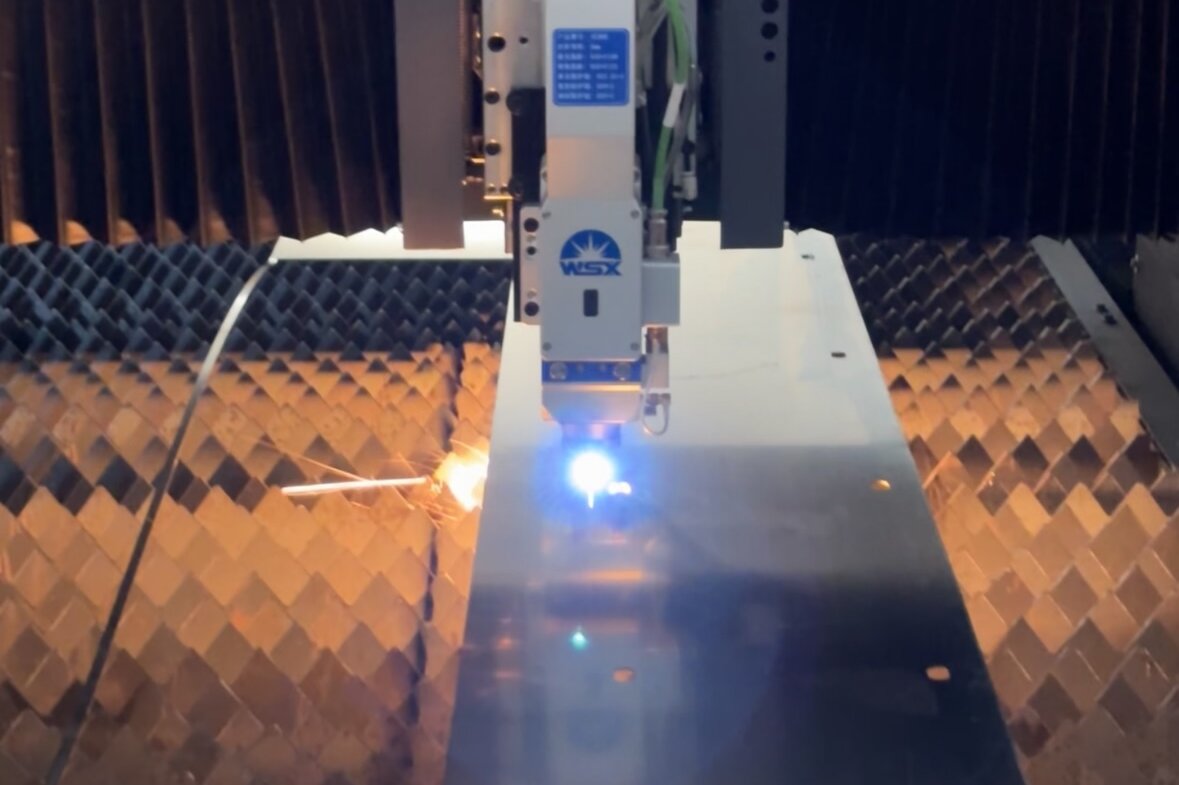

2. Laser plate cutting machine: efficient cutting of load-bearing plates and other parts

The laser plate cutting machine is a device that uses a laser beam to cut metal plates, which has the characteristics of high precision and high efficiency. In the production of agricultural carts, load-bearing plates and other flat parts are usually cut by laser plate cutting machines.

The cutting speed of the laser plate cutting machine is fast, and the heat effect during the cutting process is small, which can effectively reduce the deformation of the workpiece. Therefore, the laser plate cutting machine is widely used in the processing of load-bearing plates, handlebars and other parts of agricultural carts.

Application examples of laser plate cutting machines

Laser plate cutting machines can accurately cut metal plates according to design requirements, and the edges of the cut load-bearing plates are smooth and accurate in size. In addition, laser plate cutting machines can also achieve multiple cuts of different shapes on the same workpiece, improving production efficiency and material utilization.

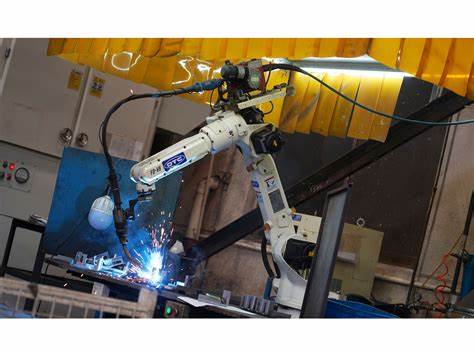

3. Laser welding machine: efficient and precise welding process

Laser welding machine is a device that uses laser beams for high-energy density welding and is widely used in the connection of metal parts. The advantages of laser welding machines are that their welding process is precise, the heat-affected zone is small, the weld is beautiful and has high strength.

The efficiency and precision of laser welding eliminate the need for a large amount of post-processing during the production process, which can greatly improve production efficiency. Laser welding machines can achieve precise control during the welding process, avoiding deformation, cracks and pores that are common in traditional welding.

Application examples of laser welding machines

During the frame welding process of agricultural carts, the various components of the frame are connected by laser welding machines. For example, the welding parts of the support pipe and the load-bearing plate of the frame are precisely welded by laser welding machines, which can ensure that the weld is smooth and firm without excessive thermal deformation. The high efficiency and high precision of the laser welding machine have greatly improved the degree of automation in the production of agricultural carts.

2.4 Pipe bending machine: Precise bending of frame pipes

Pipe bending machines are mainly used to bend metal pipes. Traditional manual pipe bending is not only time-consuming and labor-intensive, but also easily causes deformation of the pipes. The emergence of pipe bending machines solves this problem.

The pipe bending machine can achieve efficient and precise pipe bending operations by accurately controlling the bending angle and radius through the CNC system. For agricultural carts, pipe bending machines are mainly used for bending frame support components to ensure the stability and load-bearing capacity of the frame structure.

Application examples of pipe bending machines

During the frame manufacturing process, pipe bending machines can bend pipes multiple times and ensure that the bending angle of each section of pipe is accurate. For example, the front and rear support parts and handle parts of the frame usually need to be precisely bent according to the design drawings. Pipe bending machines can provide a variety of bending solutions according to different needs.

Summary

The application of modern mechanical equipment has significantly improved the production efficiency of agricultural carts. From design to material selection, to laser cutting, laser welding, pipe bending and assembly, modern machinery and equipment provide strong support for the high-quality production of agricultural carts.