The introduction of modern laser technology, pipe bending machines and laser welding technology has made the production of metal baking trays more efficient and accurate. This article will discuss the production process of metal baking trays in detail, and combine equipment such as laser plate cutting machines, laser pipe cutting machines, pipe bending machines and laser welding machines to introduce their applications and advantages in baking tray production.

1. Application of laser plate cutting machine in the production of metal baking trays

In the process of making metal baking trays, laser cutting is one of the most commonly used processes, especially the application of laser plate cutting machine, which can greatly improve the precision and efficiency of cutting.

1.1 Working principle of laser plate cutting machine

The laser plate cutting machine irradiates the surface of the metal sheet with a high-power laser beam, uses the heat energy of the laser to locally heat the metal to a molten or vaporized state, and then blows away the molten or vaporized metal through a high-pressure airflow to complete the cutting. Compared with traditional mechanical cutting methods, laser cutting has the following significant advantages:

·High precision: The laser plate cutting machine can cut with extremely high precision and can meet the delicate shape requirements of the metal baking tray surface.

·Smooth cutting: The cut of the laser plate cutting machine is smooth and does not require subsequent secondary processing.

·High degree of automation: The laser plate cutting machine can be programmed to automatically complete cutting tasks of different shapes and sizes, greatly improving production efficiency.

1.2 Application of laser plate cutting machine in baking tray production

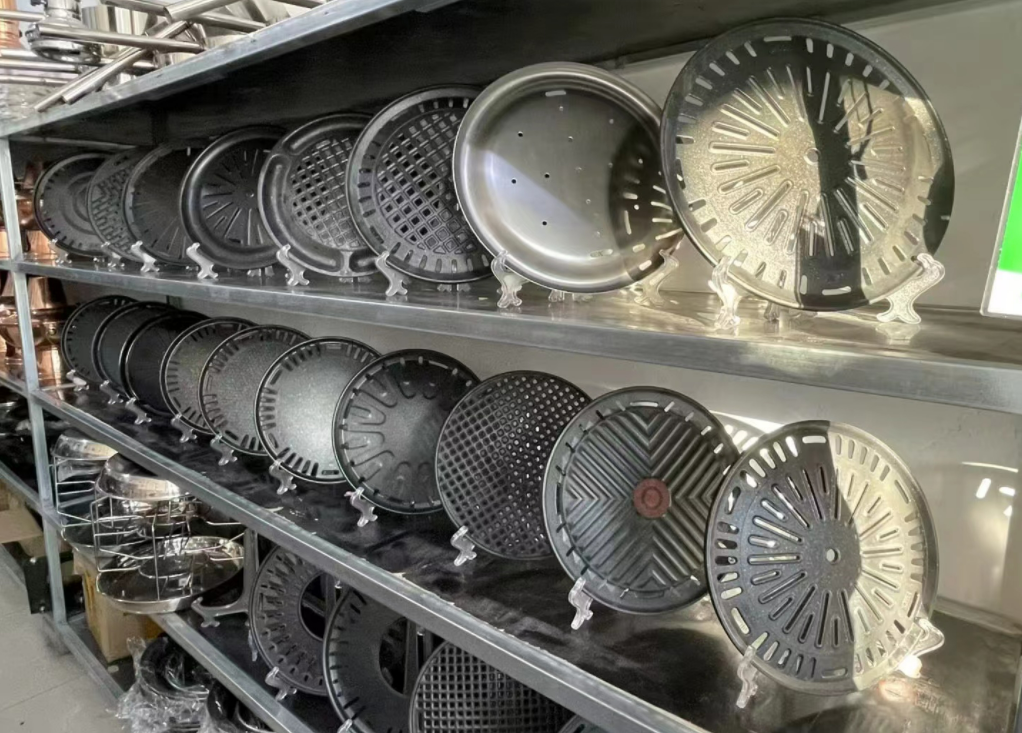

The laser plate cutting machine can accurately cut the bottom, edge and other required holes and patterns of the baking tray. The specific applications are as follows:

·Bottom cutting: The laser plate cutting machine can easily achieve high-precision plane cutting to ensure the smoothness and flatness of the bottom of the baking tray.

·Edge cutting and chamfering: The laser plate cutting machine can cut and chamfer the edges of the baking tray to increase the aesthetics and safety of the baking tray.

·Hole and pattern cutting: The laser plate cutting machine can cut various complex holes and patterns on the metal plate to meet different functional requirements.

2. Combined application of laser tube cutting machine and tube bending machine

In addition to metal sheets, metal baking trays also involve the use of tubes in some designs. Laser tube cutting machines and tube bending machines play an important role in this link. They can accurately cut and bend tubes according to needs, providing a perfect solution for the frame and support structure of the baking tray.

2.1 Working principle of laser tube cutting machine

The working principle of laser tube cutting machine is similar to that of laser plate cutting machine, but it is specially used for cutting tubes. Compared with traditional mechanical tube cutting, laser tube cutting machine has the following advantages:

·High precision and high efficiency: Laser tube cutting machine can accurately cut tubes of various specifications and shapes. It can cut quickly and greatly improve production efficiency.

· No fixture required: The automatic tube alignment function of the laser tube cutting machine eliminates the need for fixed fixtures during the cutting process, thereby reducing the maintenance and adjustment costs of the equipment.

· Complex cutting: The laser tube cutting machine can cut complex tube shapes, such as bevel cuts, round holes, rectangular holes, etc.

2.2 Working principle and application of tube bending machine

The tube bending machine is a device specially used for bending tubes. It bends the tube according to the design requirements through a series of mechanical forces to form the required angle and shape. Common types of tube bending machines include CNC tube bending machines, hydraulic tube bending machines, etc., which can be adjusted according to different tube types and bending requirements.

· Precise bending: The tube bending machine can accurately control the bending angle, radius and bending direction to ensure that the geometry of the tube meets the design requirements.

· No joints: The tube bending machine can ensure the continuity of the tube and enhance the stability of the structure.

· Efficient automation: Modern tube bending machines use CNC technology to achieve automated tube bending, greatly improving production efficiency and consistency.

In the production process of metal baking trays, pipe bending machines are often used to make the brackets or frames of the baking trays. The pipe bending machine can perfectly adapt these brackets and frames to the design requirements of the baking trays by precisely controlling the bending process.

3. The key role of laser welding machines

Laser welding machines play an important role in the welding process of metal baking trays.

3.1 Working principle of laser welding machines

Laser welding machines irradiate metal joints with high-energy laser beams, heat the metal to a molten state, and form a connection in the molten pool. Laser welding machines have the following characteristics:

·High temperature concentration: The heat affected zone of the laser welding machine is small during the welding process, which avoids excessive heating and deformation of the metal.

·High precision: The laser welding machine is suitable for thin-walled metal or complex workpieces, and can ensure the strength and appearance of the welded joints.

·Non-contact: The welding process of the laser welding machine is conducive to improving the welding quality.

3.2 Application of laser welding machines in baking tray production

In the production of metal baking trays, laser welding machines are mainly used to firmly connect the various parts of the baking tray to ensure the overall structural stability of the baking tray. Specific applications are as follows:

· Welding metal plates and pipes: The laser welding machine can accurately connect the cut metal plates and the bent metal pipes to ensure that the welding joints are firm and defect-free.

· Precision welding: The laser welding machine can provide high-precision welding.

· Beautiful welding: The joints of the laser welding machine are usually smooth, and the appearance after welding is more beautiful.

4. Summary

The combination of laser plate cutting machine, laser tube cutting machine, tube bending machine and laser welding machine not only improves production efficiency, but also improves product quality and market competitiveness. With the continuous advancement of technology, the application of laser technology in the field of metal processing will be more extensive.