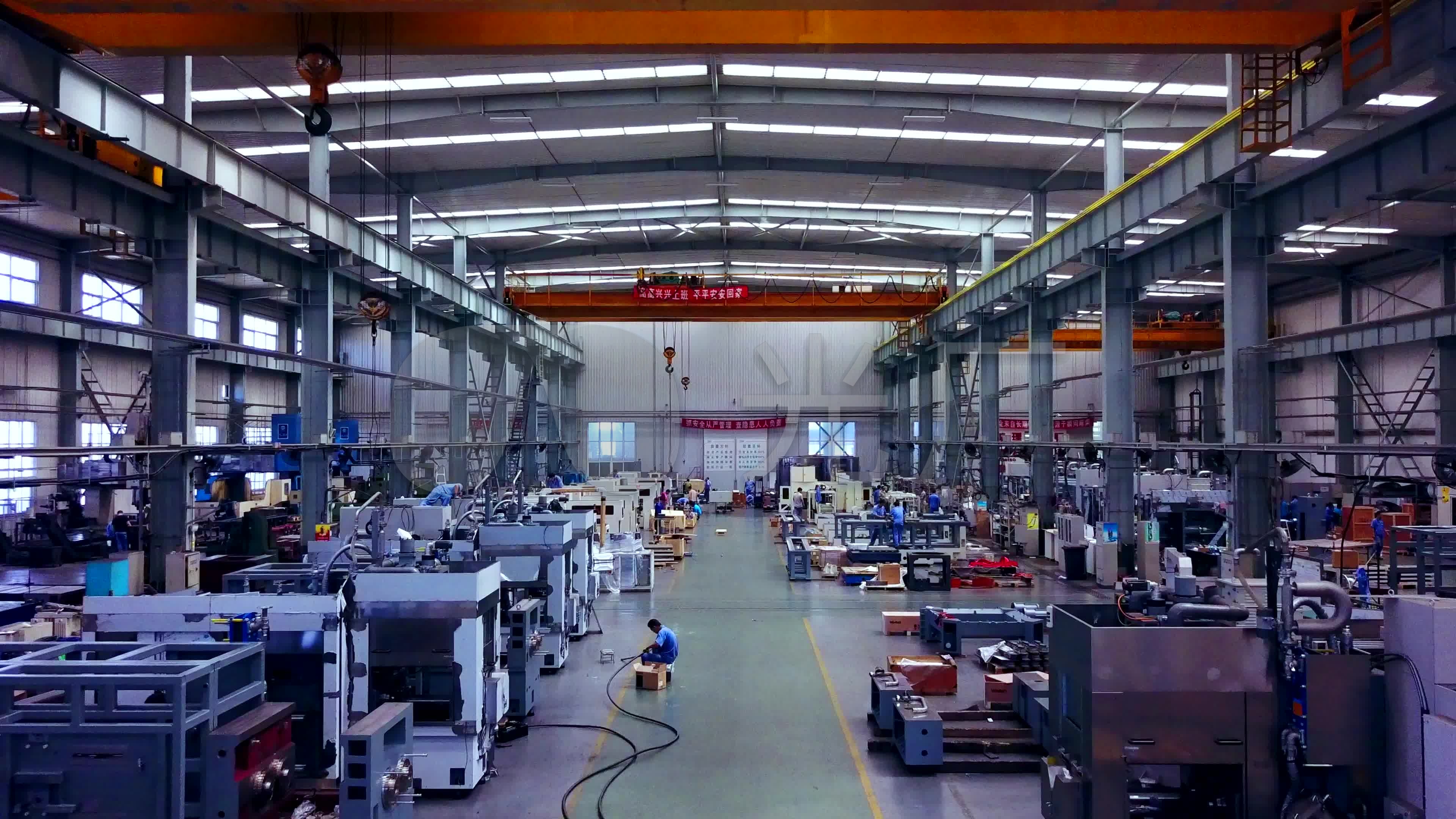

Metal office partitions have become increasingly popular in modern workspaces due to their durability, clean aesthetics, and flexibility in design. Central to this workflow are three major types of advanced equipment: the laser pipe cutting machine, the pipe bending machine, and the laser welding robot.This article explores in detail how these machines function and how they contribute to the overall manufacturing process.

1. Laser Pipe Cutting Machine: Precision at the First Step

The production of metal office partitions begins with the processing of raw metal pipes, typically made of steel, stainless steel, or aluminum. The laser pipe cutting machine serves as the first and most crucial stage because it determines the dimensional accuracy and structural quality of all subsequent components.

High-Precision Cutting

Laser pipe cutting machines use a focused laser beam to cut through metal pipes with extreme accuracy. Compared with traditional mechanical cutting methods, such as sawing or drilling, laser pipe cutting machine offers several advantages:

Minimal tolerance errors, ensuring that each pipe matches the exact dimensions required.

Clean cut edges, reducing the need for secondary finishing.

No deformation, because the heat-affected zone is minimal.

Ability to cut complex shapes, including round holes, slots, bevels, and notches.

For office partitions, these capabilities are essential because the partition frame must fit together with millimeter-level precision. Any deviation can lead to assembly issues, misalignment, or weakened structural integrity.

Efficient and Flexible Production

Laser pipe cutting machines allow manufacturers to switch quickly between different cutting patterns through digital programming. This flexibility is particularly important for customized office partitions, where clients often require unique geometries, decorative patterns, or modular structures.

In addition:

Automated feeding systems enable continuous, high-volume production.

Computer-controlled operation ensures repeatability, producing identical parts at scale.

Nesting optimization software helps reduce material waste, lowering overall production costs.

Foundation for Structural Stability

The accuracy delivered by the laser pipe cutting machine ensures that each component connects seamlessly during assembly. Because the pieces fit together perfectly, the final office partition structure remains stable, durable, and aesthetically consistent. In essence, the laser pipe cutting machine lays the groundwork for all subsequent manufacturing stages.

2. Pipe Bending Machine: Shaping the Structure

Once the pipes are accurately cut, the next major step involves shaping them into the required design forms. This is where the pipe bending machine comes into play. Pipe bending machines enable these complex shapes to be produced with accuracy and repeatability.

Controlled, High-Quality Bending

Modern CNC pipe bending machines use servo-driven mechanisms that precisely control the bending radius, angle, and speed.

Compatibility With Multi-Material pipes

Pipe bending machines can work with various metals, including:

Stainless steel, commonly used for premium office partitions.

Aluminum, chosen for lightweight and corrosion-resistant partitions.

Carbon steel, preferred for high-strength applications.

Each material has distinct mechanical properties, and advanced pipe bending machines automatically adjust pressure and bending parameters to prevent flaws.

Enhancing Design Possibilities

By providing designers with more flexibility, pipe bending machines play a vital role in meeting both functional and artistic requirements in contemporary workspace environments.

3. Laser Welding Robot: Ensuring Structural Integrity and Aesthetic Perfection

The final major stage in manufacturing metal office partitions is the assembly and joining of cut and bent components. The laser welding robot is responsible for this step, delivering high-speed, high-quality welds with exceptional precision.

Consistent, High-Strength Welding

Laser welding robot offers significant advantages over conventional arc welding:

Deep penetration with minimal heat distortion.

Fine, smooth welding seams, ideal for visible frame areas.

Strong, reliable joints, ensuring long-term durability.

Laser welding robots control enhances these advantages by ensuring that every weld follows the exact programmed path.

Automation and Efficiency

Using laser welding robot dramatically increases production efficiency:

Laser welding robots can work continuously with minimal downtime.

They ensure uniform quality, reducing the chance of rework.

Automated welding reduces labor costs and enhances safety.

This automation is especially valuable in large-scale production of office partitions, where hundreds of identical frames may need to be assembled each day.

Perfect Aesthetic Finish

Laser welding robot produces:Fine, barely visible weld seamsMinimal post-weld polishing

Smooth joints that blend seamlessly with powder-coated finishes

These qualities help manufacturers achieve a clean, modern look that complements contemporary office design trends.

Conclusion

The production of metal office partitions is a sophisticated and highly technical process that relies on three essential pieces of equipment: the laser pipe cutting machine, pipe bending machine, and laser welding robot. Each machine contributes uniquely to the workflow:The laser pipe cutting machine ensures precise dimensions and clean edges for perfect component fit.The pipe bending machine shapes the structural elements while maintaining material integrity and design flexibility.The laser welding robot delivers strong, consistent, and visually appealing welds that guarantee durability and aesthetic quality.