With the development of modern industrial technology, high-precision equipment such as laser cutting machines and laser welding machines are widely used in the production process of metal ovens, making these steps more efficient, precise and reliable. This article will discuss in detail the key technologies of "cutting and forming" and "welding and assembly" in the production process of metal ovens, combined with the use of modern mechanical equipment, and deeply analyze the operation process, technical requirements and precautions of each step.

1. Cutting and forming: the combination of precision and efficiency

In the production of metal ovens, cutting and forming are the first steps.

1.1 Advantages of laser cutting technology

Laser cutting machines have the following significant advantages:

High-precision cutting: For parts that require precise size and details in the production of metal ovens (such as door frames, brackets, insulation layer grooves, etc.), laser cutting is the most ideal choice.

Fast cutting speed: The processing speed of laser cutting is relatively fast, usually several times higher than that of traditional mechanical cutting methods, which greatly improves production efficiency.

High degree of automation: Modern laser cutting machines mostly use CNC systems, which can directly control the cutting path and parameters through computers, reduce manual intervention, and reduce operational risks and errors.

Strong adaptability: Laser cutting can not only cut common carbon steel, stainless steel and aluminum alloys, but also cut thicker metal sheets to meet the processing needs of various materials.

1.2 Operation process of laser cutting machine

The workflow of laser cutting machine can be roughly divided into the following steps:

Material preparation: First, prepare the required metal sheets according to the design drawings. Common materials include stainless steel, carbon steel, aluminum alloy, etc.

Drawing input: Input the design drawings of the metal oven into the CNC system of the laser cutting machine through CAD (computer-aided design) software.

Laser cutting: After the laser cutting machine is started, the laser beam focuses on the metal surface, and the CNC system automatically tracks the cutting path on the drawing to perform high-precision cutting of the metal.

Post-cutting processing: After the laser cutting machine is finished, the cutting surface is usually polished or cleaned to remove burrs and residues generated during the cutting process to ensure that the surface of the cut part is smooth and defect-free.

1.3 Requirements for finished products in cutting and forming

The requirements for finished products in the cutting and forming stages are very strict. Not only must they meet the dimensions of the design drawings, but they must also ensure the flatness, smoothness and accuracy of the parts.

In order to ensure the cutting quality, the laser power, cutting speed, focal length and other parameters need to be adjusted during the laser cutting process to adapt to metal sheets of different thicknesses and materials.

2. Welding and assembly: precise docking and strong connection

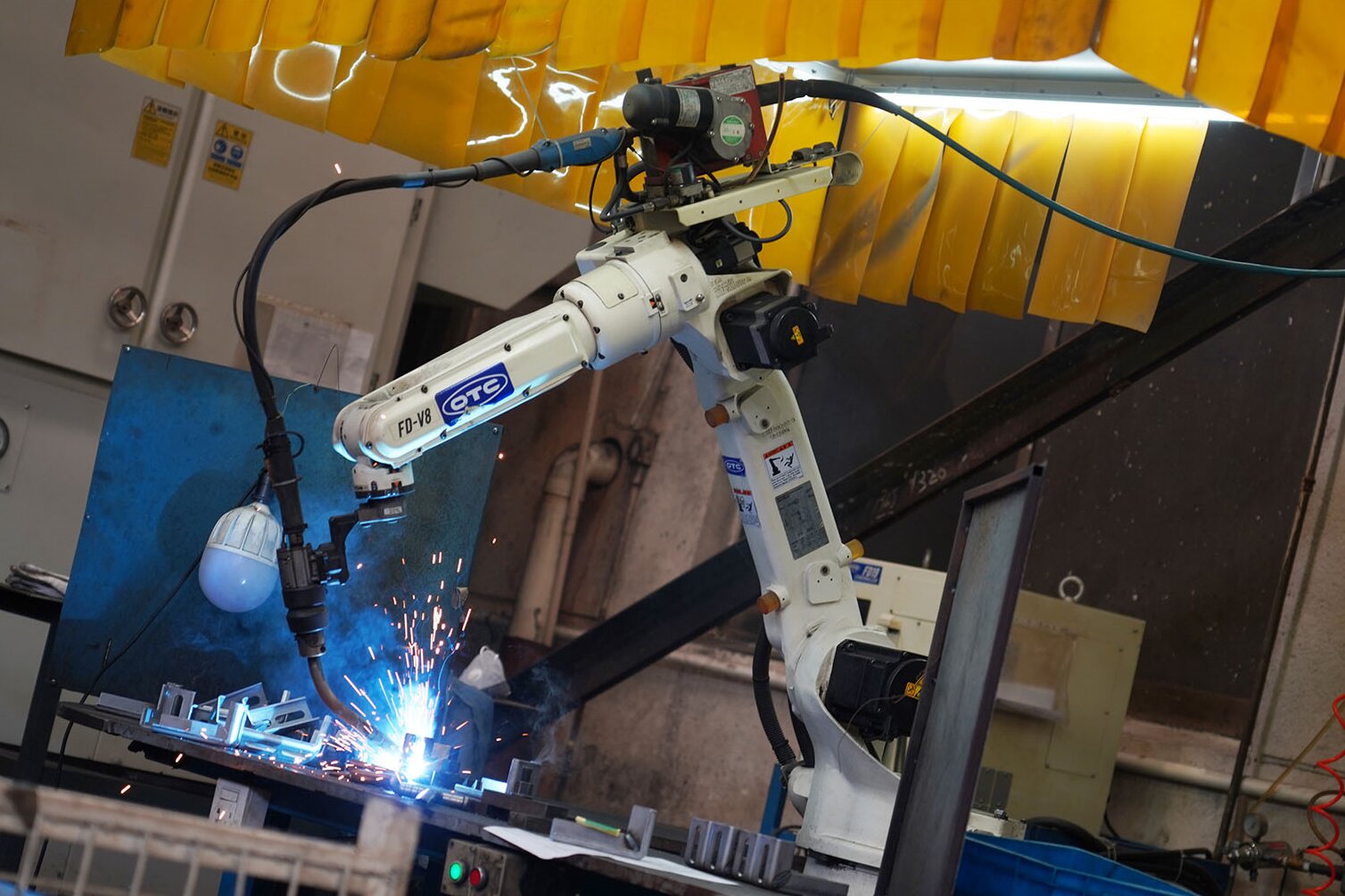

In the production process of metal ovens, welding and assembly play a vital role. The introduction of laser welding technology has brought the efficiency and precision of this link to a new level.

2.1 Advantages of laser welding technology

Laser welding technology uses a high-energy laser beam to heat the metal to a molten state and form a strong welded joint at the contact point of the two metal materials. Laser welding has the following advantages:

High-precision welding: Laser welding has extremely high focusing ability and can weld extremely small joints, which is suitable for precise metal joining. In metal ovens, many parts need to be welded to small areas, and laser welding machines can meet these fine requirements.

Fast welding speed: Laser welding speed is very fast and can complete welding in a short time, greatly improving production efficiency and reducing production cycle.

Small welding heat-affected zone: The heat-affected zone of laser welding is relatively small, which means that the risk of thermal deformation can be reduced during welding.

Strong adaptability: Laser welding is not only suitable for various metals, but also can handle complex welding tasks, such as spot welding in precise positions or line welding over large areas.

2.2 Operation process of laser welding machine

The workflow of laser welding machine mainly includes the following steps:

Preparation: Before welding, the cut metal parts need to be pre-assembled according to the design requirements.

Welding parameter setting: According to the type and thickness of the metal material, set appropriate parameters such as laser power, welding speed and focal length.

Laser welding: During the welding process, the laser beam accurately irradiates the metal joint, instantly heats and melts the metal to form a firm welded joint.

Post-weld treatment: After laser welding is completed, surface cleaning and grinding are usually required to remove spatter and welding slag during welding, and ensure that the weld joint is flat and smooth.

2.3 Quality control of welding and assembly

Quality control of welding and assembly is crucial, which directly affects the structural stability and safety of metal ovens.

To ensure welding quality, laser welding machines are usually equipped with high-precision detection systems to monitor parameters such as temperature, spot, welding speed, etc. during welding in real time.

3. Conclusion: Modern equipment improves production efficiency and precision

The production process of metal ovens involves a series of process links from cutting and forming to welding and assembly. In this process, the introduction of laser cutting machines and laser welding machines has greatly improved production efficiency and processing accuracy, ensuring the quality and safety of metal ovens.