The application of equipment such as laser pipe cutting machines, pipe bending machines and laser welding machines has greatly improved the production efficiency, precision and aesthetics of metal stair railings. This article will introduce the production process of metal stair railings in detail, focusing on the application and advantages of modern equipment such as laser pipe cutting machines, pipe bending machines and laser welding machines in this process.

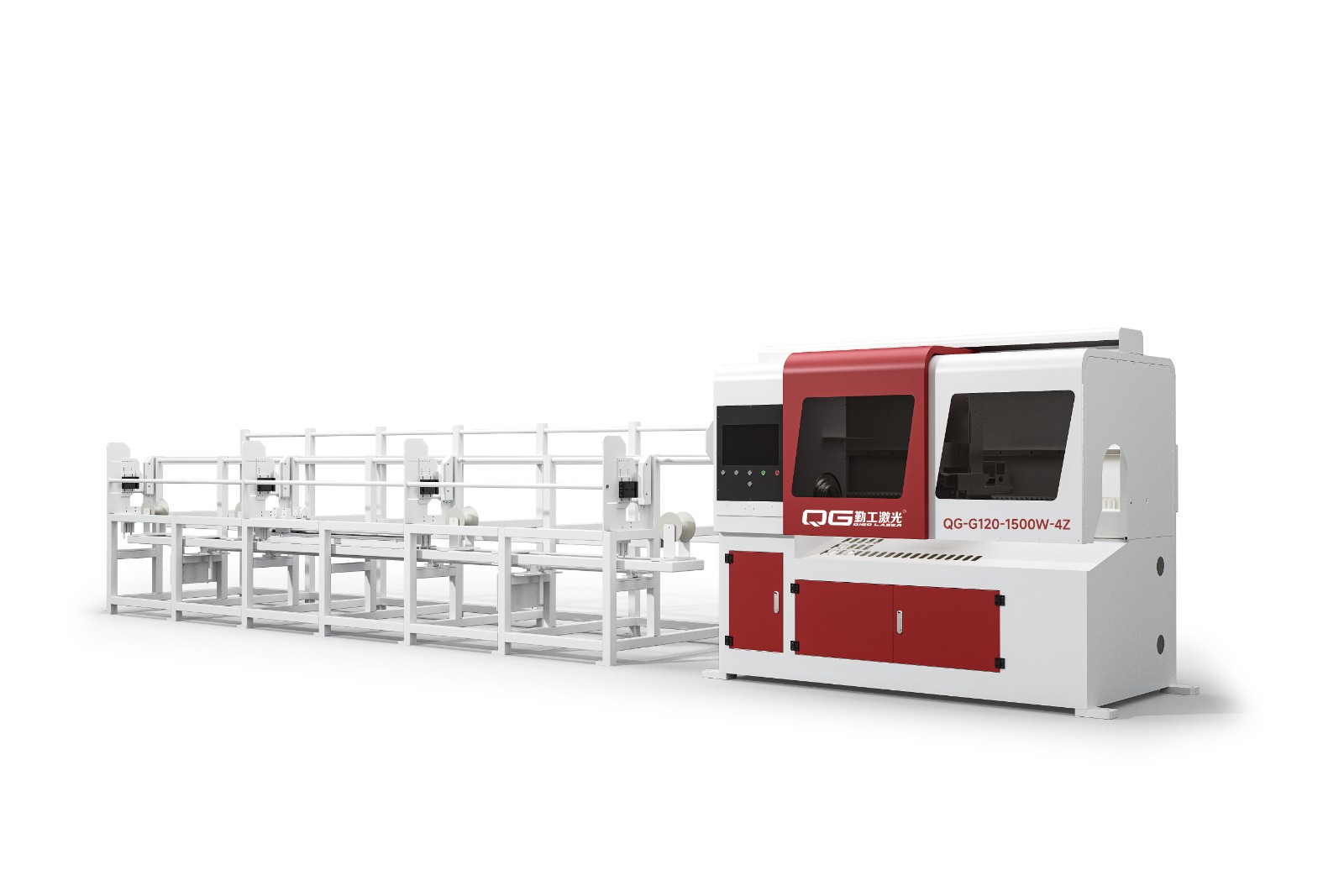

1. Application of laser pipe cutting machine in the production of metal stair railings

Laser pipe cutting machine is a high-tech equipment that uses laser beams to cut metal pipes. Laser pipe cutting machine has the advantages of high cutting accuracy, fast cutting speed and small heat-affected zone, which is very suitable for the production of metal stair railings.

1.1 High-precision cutting

Laser pipe cutting machine can accurately cut pipes into the required shape. The surface of the pipe after cutting is smooth, and basically no subsequent secondary processing is required.

1.2 Efficient production

The cutting speed of the laser pipe cutting machine is much higher than that of traditional mechanical cutting equipment, which can significantly improve production efficiency. The use of laser pipe cutting machine can greatly shorten the production cycle and improve the overall efficiency of the production line.

1.3 Diversified cutting methods

The laser pipe cutting machine can perform various types of cutting according to design requirements, including straight line cutting, curve cutting, hole cutting, etc. For some complex-shaped railing components, the laser pipe cutting machine can accurately cut according to the design requirements to meet the personalized needs of customers.

1.4 Save materials and costs

The high-precision cutting of the laser pipe cutting machine can also minimize material waste and reduce production costs.

2. Application of pipe bending machine in the production of metal stair railings

The pipe bending machine is a device used for bending metal pipes and is widely used in the production of metal stair railings. Especially for railing components with curved shapes, the pipe bending machine can provide precise bending control to ensure the structural stability and aesthetics of the railings.

2.1 Accurately control the bending angle and radius

The pipe bending machine uses the CNC system to accurately control the bending angle, radius and bending position to ensure that the bending of each pipe meets the design requirements. Even for more complex bending shapes, the pipe bending machine can accurately complete it.

2.2 Applicable to a variety of materials

The pipe bending machine is not only suitable for common materials such as ordinary steel pipes and stainless steel pipes, but also for bending special materials such as aluminum alloys. The diverse adaptability of the pipe bending machine makes it have a wide range of application prospects in railing production.

2.3 Improve production efficiency

The pipe bending machine can realize automatic operation through CNC technology, greatly improving production efficiency. Especially in mass production, the high efficiency of the pipe bending machine can effectively shorten the production cycle and increase the overall production capacity of the production line.

2.4 Reduce labor costs

Automated pipe bending machines not only improve production efficiency, but also reduce dependence on manual operation. It can effectively reduce production costs, especially in large-scale production, the advantages of pipe bending machines are more prominent.

3. Application of laser welding machine in the production of metal stair railings

Laser welding machine has the advantages of high precision, high efficiency and low thermal impact, and is widely used in the welding of metal stair railings.

3.1 High-precision welding

The laser welding machine can perform high-precision control on the welding part through precise laser beam focusing to ensure that the weld is smooth and flat. Compared with traditional welding methods, laser welding machines have obvious advantages in the strength and appearance of joints.

3.2 Fast welding speed

Laser welding machines can complete the welding of complex parts in a short time, greatly improving production efficiency. For metal stair railings that require a large amount of welding, laser welding machines can significantly shorten the production cycle and improve production capacity.

3.3 Small heat-affected zone

Another significant advantage of laser welding machines is the small heat-affected zone. Therefore, laser welding machines are particularly suitable for welding precision parts, and can ensure the structural stability and appearance quality of metal stair railings after welding.

3.4 High degree of automation

Modern laser welding machines are usually equipped with CNC systems, which can realize automated welding and reduce manual operation errors.

4. Conclusion

With the widespread application of modern equipment such as laser pipe cutting machines, pipe bending machines, and laser welding machines, the production process of metal stair railings has been significantly improved. In the future, with the continuous development of science and technology, the production process of metal stair railings will be more intelligent and automated, and the upgrading of equipment will further promote the progress of the industry.