In modern furniture manufacturing, the metal bedside cabinet frame has become a popular structural solution due to its strength, durability, clean appearance, and compatibility with minimalist and industrial design styles.To meet these requirements, manufacturers increasingly rely on advanced automated equipment such as laser pipe cutting machines, pipe bending machines, and laser welding robots.

Overview of the Metal Bedside Cabinet Frame Production Process

A metal bedside cabinet frame typically consists of steel or aluminum pipes that form the main load-bearing structure. These pipes are cut to precise lengths, shaped into specific angles or curves, and then joined together through welding to create a rigid and stable frame. The general production flow includes the following steps:

Material selection and preparation

Laser pipe cutting

pipe bending and forming

Fixture positioning and laser welding

Surface treatment and quality inspection

Among these steps, laser pipe cutting machines, pipe bending machines, and laser welding robots play a decisive role in determining the accuracy, efficiency, and overall quality of the final product.

The Role of the Laser pipe Cutting Machine in Frame Manufacturing

The laser pipe cutting machine is the first major piece of equipment used in the production of a metal bedside cabinet frame. Its primary function is to cut metal pipes—round, square, or rectangular—into precise lengths and shapes according to design specifications.

High-Precision Cutting and Complex Geometry

In contrast, a laser pipe cutting machine uses a high-energy laser beam controlled by CNC software to perform extremely accurate cuts. This precision is crucial for bedside cabinet frames, where even small dimensional deviations can affect assembly accuracy and visual symmetry.

Efficiency and Material Utilization

Another important advantage of laser pipe cutting machines is their high production efficiency. Once the cutting program is set, the machine can operate continuously with minimal human intervention. Automated feeding systems further improve throughput by loading raw pipes and unloading finished parts.

Additionally, laser cutting machine optimizes material utilization. Advanced nesting software arranges cutting patterns to minimize waste, which is particularly valuable when working with high-quality steel or aluminum. Reduced material waste not only lowers production costs but also supports environmentally responsible manufacturing practices.

Consistency and Preparation for Downstream Processes

Consistency is essential for automated production. Laser pipe cutting machines ensure that every cut pipe is identical, which simplifies the pipe bending and welding stages.

The Function of the pipe Bending Machine in Structural Forming

After cutting, the metal pipes must be shaped into the required forms. This is where the pipe bending machine plays a vital role.

Accurate Bending for Structural Integrity

Pipe bending machines apply controlled force to bend metal pipes at precise angles and radii without flattening or cracking the material. Modern CNC pipe bending machines can execute complex multi-angle bends with high repeatability.

Adaptability to Different Designs

Furniture design trends change frequently, and manufacturers must be able to adapt quickly. pipe bending machines offer great flexibility, as new bending programs can be created and adjusted digitally. Whether the design calls for sharp angular bends or smooth, continuous curves, the pipe bending machine can accommodate various styles without the need for expensive tooling changes.

This adaptability supports mass customization, enabling manufacturers to produce different bedside cabinet models on the same production line with minimal downtime.

Reducing Manual Labor and Errors

Before the widespread use of pipe bending machines, bending was often performed manually or with semi-automatic equipment, which required skilled operators and involved a higher risk of inconsistency.

The Importance of Laser Welding Robots in Frame Assembly

Once the pipes are cut and bent, they must be joined together to form a complete metal bedside cabinet frame. Laser welding robots are the key technology used in this assembly stage.

High-Strength, Clean Welds

Laser welding robots use a focused laser beam to fuse metal components together with exceptional precision. Compared to traditional arc welding, laser welding produces narrower weld seams, deeper penetration, and minimal heat-affected zones.

Automation and Repeatability

Laser welding robot systems are programmed to follow exact welding paths, ensuring consistent results across large production batches. This repeatability is essential for maintaining uniform quality in mass production. Once the welding parameters are optimized, the robot can perform the same operation thousands of times with minimal variation.

Automation also significantly improves production speed. A laser welding robot can complete multiple welds in a fraction of the time required for manual welding, increasing overall factory output.

Improved Safety and Reduced Distortion

Laser welding robot generates less heat than conventional welding methods, which helps reduce thermal distortion of thin-walled pipes. This is especially beneficial for bedside cabinet frames, where dimensional accuracy and straightness are critical.

From a safety perspective, laser welding robot reduces workers’ exposure to intense light, heat, and fumes. Operators can supervise the process from a safe distance, focusing on quality control and system monitoring rather than direct welding tasks.

Integration of Equipment and Quality Control

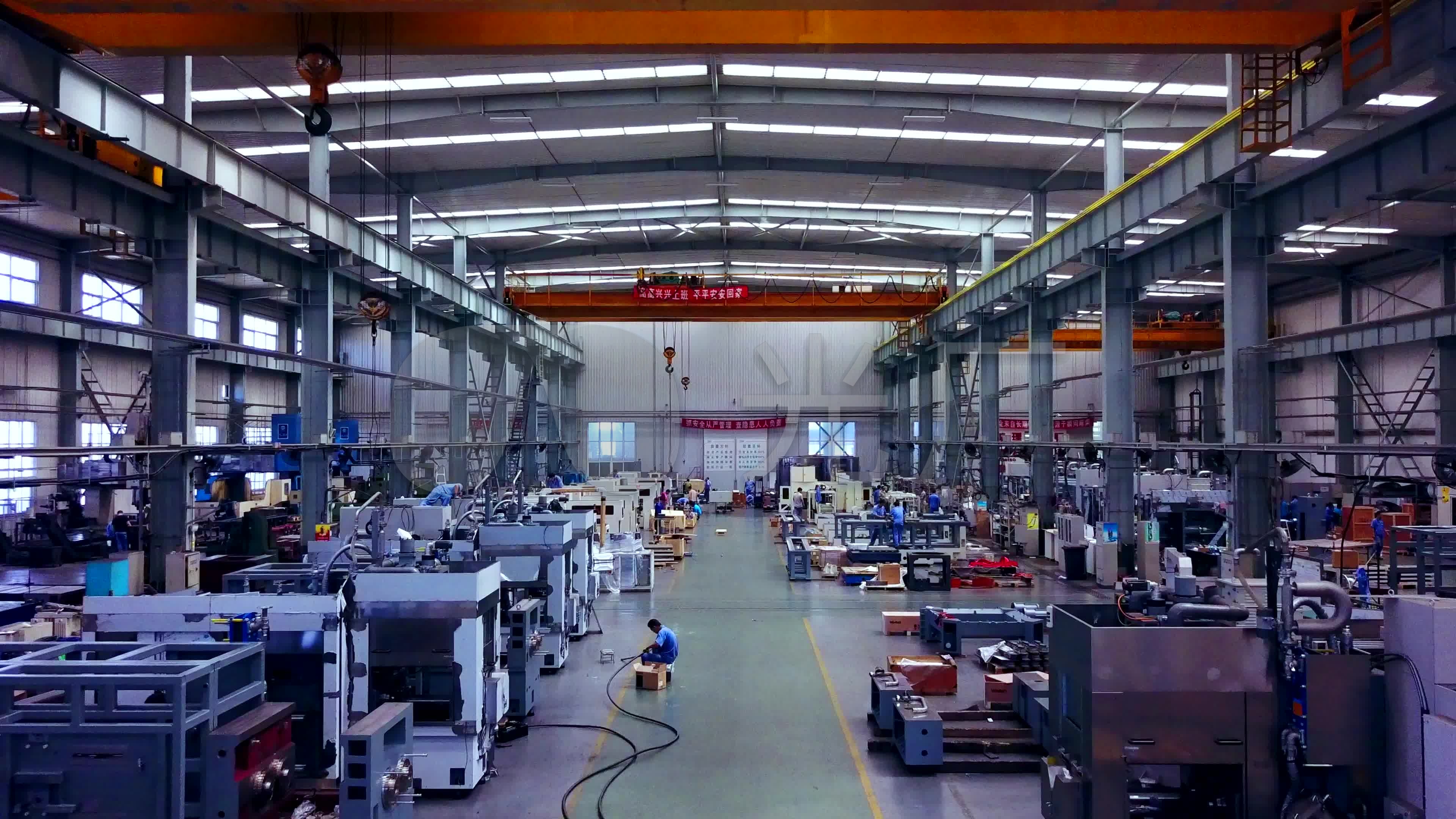

The true strength of modern metal bedside cabinet frame production lies in the integration of laser pipe cutting machines, pipe bending machines, and laser welding robots into a cohesive manufacturing system. Data from the design stage flows seamlessly into each machine, ensuring consistency from raw material to finished frame.

Conclusion

The production of a metal bedside cabinet frame is a sophisticated process that relies heavily on advanced manufacturing technologies. Laser pipe cutting machines provide precision and efficiency in material preparation, pipe bending machines shape components with accuracy and flexibility, and laser welding robots ensure strong, clean, and consistent assembly.