In modern manufacturing, the production process of a metal colander is not just a simple production process, it involves the collaborative work of multiple high-precision machines. This article will introduce in detail the process from the cutting of metal raw materials to the formation of finished products, including the role of key equipment such as pipe cutting machines, plate cutting machines, welding machines, and cone pipe machines. Through this process, we can have a deeper understanding of the production process of metal products and the technical details behind them.

Raw material preparation and preliminary processing

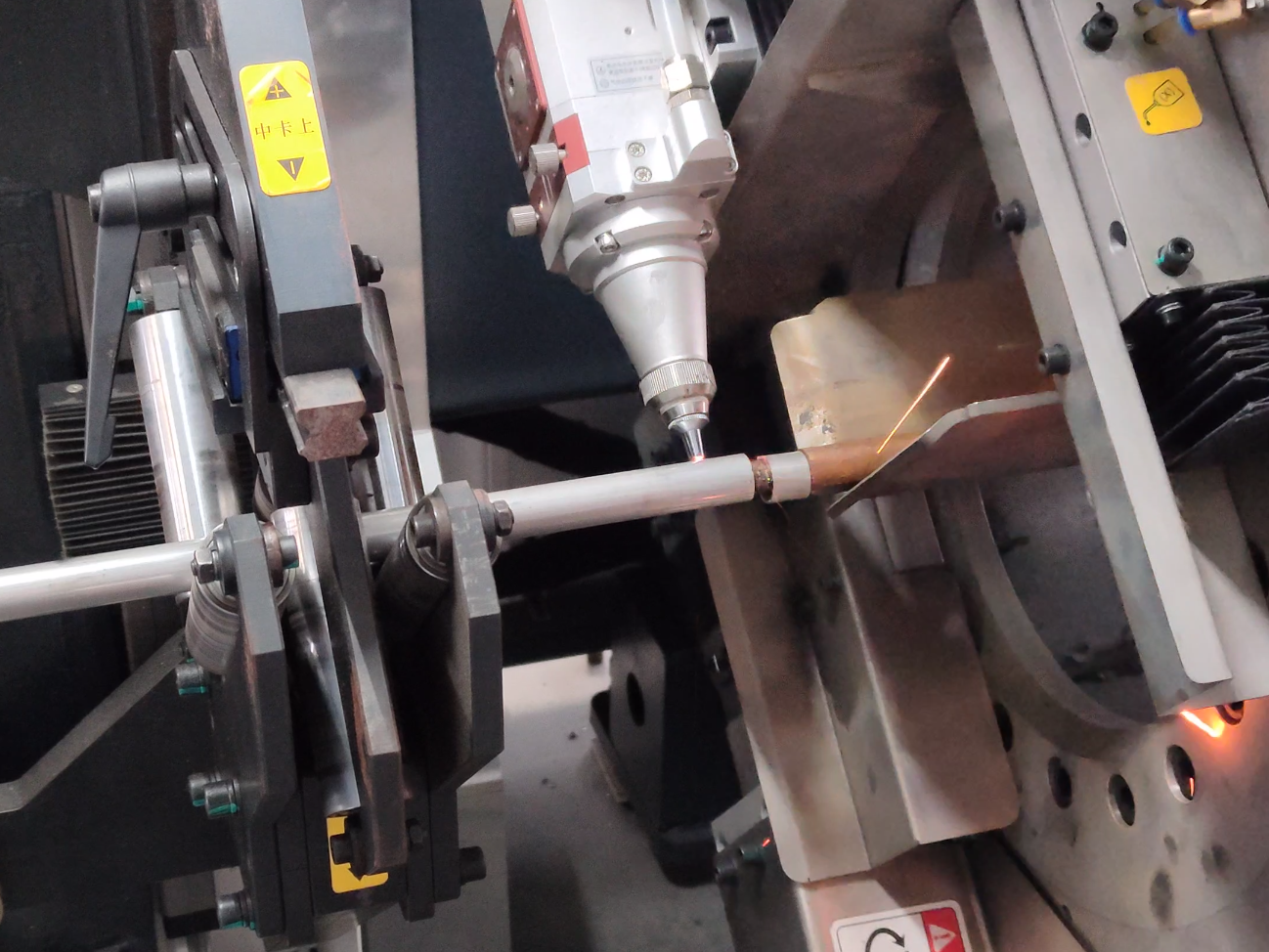

1. Use of laser pipe cutting machine

The production of metal colander begins with the preparation of raw materials. The main body of the colander is generally made of stainless steel or aluminum alloy, and these metal materials are usually supplied in the form of pipes or plates. At this stage, the laser pipe cutting machine plays a vital role.

The main function of the laser pipe cutting machine is to cut long pipes into lengths suitable for subsequent processing. Usually, the main part of the metal colander needs to be processed from a metal pipe, so the accuracy of the laser pipe cutting machine directly affects the quality of the final product. When using a laser pipe cutting machine, the operator first needs to set the cutting length and then place the pipe on the workbench of the laser pipe cutting machine. The machine uses a rotating blade to accurately cut the pipe into the required length. This process requires the machine to have high cutting accuracy and stability to ensure the consistency of each cutting section.

2. Application of laser cutting machines

In addition to pipes, the bottom and handle of the colander usually need to be cut out of metal sheets. At this time, the laser cutting machines becomes a key equipment. The laser cutting machines can cut metal plates of varying thicknesses into the required shape and size. The operator needs to set the cutting path according to the design drawing and place the metal plate on the workbench of the laser cutting machines.The laser cutting machines uses a high-voltage blade or laser beam to accurately cut the metal plate to form the holes at the bottom of the colander and the basic shape of the handle. In addition, a punch is used to form the corresponding arc at the bottom of the colander.

In this process, the performance of the laser cutting machines and the sharpness of the tool have an important influence on the final cutting effect. The accuracy ofthe laser cutting machines directly determines the cutting quality of the metal plate, which in turn affects the performance and appearance of the colander.

Assembly and welding of parts

1. The role of the welding machine

After cutting, the various parts of the metal colander need to be assembled by a welding machine. Welding is a key step in connecting metal parts into a whole, and the welding machine ensures the structural stability and safety of the colander.

In addition to laser welding machines, there are many types of welding machines, each of which has its own unique application scenarios. During the production process of the colander, the welding machine will heat the metal parts to a molten state, and then cool and solidify to achieve the connection of the parts.

2. Optimization of welding process

In order to improve the quality of welding, manufacturers usually optimize the welding process. This includes adjusting welding parameters, selecting suitable welding materials, and optimizing the welding sequence. For example, when making the bottom of the colander, the welding process needs to ensure that the holes and outer edges at the bottom are tightly connected to avoid cracks.

In addition, in order to improve production efficiency and welding quality, some advanced manufacturing plants have also introduced automated welding systems. These systems can control the precise welding process through computers, thereby improving the consistency and reliability of welding.

Finished product processing and inspection

Application of conical tube machine

After welding is completed, the shape and size of the metal colander may need to be further adjusted. At this time, the role of the conical tube machine is particularly important. The conical tube machine is used to process the end of the metal tube into a cone shape to facilitate connection with other parts or adjust the appearance of the product.

The conical tube machine gradually processes the end of the metal tube into a cone shape by rotating and extruding. This process requires not only precise control of the taper and length, but also the uniformity of the metal during processing. The use of the conical tube machine can make the handle part of the colander better connected to the colander body, improving the overall aesthetics and practicality of the product.

After welding, the surface of the colander usually needs to be processed to remove the welding slag and uneven parts generated during the welding process. Surface treatment includes processes such as grinding, polishing and electroplating. Grinding can remove the rough parts of the surface, and polishing makes the metal surface smooth and bright. Electroplating can enhance the corrosion resistance of the metal and provide additional decorative effects.

Conclusion

From the production process of metal colanders, it can be seen that each link has an important impact on the quality and performance of the final product. Machines and equipment such as pipe cutting machines, laser cutting machines, welding machines and conical tube machine play an irreplaceable role in the production process. Through precise cutting, welding and forming processes, high-quality metal colanders are finally manufactured to meet the needs of the market and consumers.