The production of metal frames for wardrobes is a highly precise and systematic process that relies on advanced machinery to ensure quality, efficiency, and consistency. Among the key technologies that have revolutionized this industry are the laser pipe cutting machine, the pipe bending machine, and the laser welding robot.

In this article, we will delve into the functions and importance of these three machines, exploring how they contribute to each step of manufacturing high-quality metal frames.

1. Laser pipe Cutting Machine: Precision Starts Here

The first step in manufacturing a wardrobe metal frame involves cutting raw metal pipes to the required dimensions and shapes. With the advent of laser pipe cutting machines, this process has become significantly more efficient and accurate.

How It Works

Laser pipe cutting machines use high-powered lasers to cut through metal pipes with extreme precision. A focused beam of light is directed onto the surface of the metal, generating intense heat that melts or vaporizes the material at the point of contact.

Key Functions and Benefits

Accuracy and Repeatability: These laser pipe cutting machines can cut complex shapes, slots, holes, and contours with tolerances as tight as ±0.1 mm.

Flexibility: Laser pipe cutting machines can handle a variety of pipe shapes, including round, square, rectangular, and even custom profiles.

Speed and Efficiency: CNC (Computer Numerical Control) programming enables automated operation, reducing manual labor and drastically shortening production cycles.

Material Optimization: Advanced nesting software ensures optimal arrangement of parts, minimizing waste material and reducing costs.

In summary, the laser pipe cutting machine is the starting point of the wardrobe frame production line, ensuring that every piece is accurately shaped and ready for the next phase of processing.

2. pipe Bending Machine: Shaping the Structure

After cutting, many of the metal pipes must be bent to specific angles and radii to match the design of the wardrobe frame. This is where the pipe bending machine becomes indispensable.

How It Works

pipe bending machines apply force to a section of the metal pipe, causing it to bend around a die to achieve the desired angle.

Key Functions and Benefits

Consistent Bending Accuracy: The CNC pipe bending machine ensures that each bend is exactly as specified in the design. This is crucial for assembly, where even small deviations can result in misalignments.

Minimal Deformation: Modern pipe bending machines are designed to prevent flattening or wrinkling of the pipe during the bending process, maintaining both structural integrity and aesthetics.

Complex Bending Capabilities: Some wardrobe designs require multiple bends on a single piece of tubing. CNC pipe bending machines can perform these operations automatically, reducing the need for manual handling and intermediate checks.

Through pipe bending machines, the previously cut metal pipes are transformed into structural components that will later be joined to form the skeleton of the wardrobe.

3. Laser Welding Robots: Precision Joining for Long-Lasting Durability

Once the individual components have been cut and bent, the next step is to assemble them into a complete frame. This is achieved through welding, which fuses metal parts together to form strong, permanent joints. The use of laser welding robots has become a game-changer in this area.

How It Works

Laser welding robots use a high-powered laser beam to melt and fuse metal components at their joint. The robot arm, guided by a pre-programmed path, ensures precise positioning and motion throughout the welding process. This results in clean, uniform welds with minimal spatter or deformation.

Key Functions and Benefits

High Precision and Control: Laser welding robot provides extremely narrow weld seams and deep penetration, resulting in joints that are both strong and visually clean.

Repeatability: The robotic system of laser welding robot ensures that every weld is performed in exactly the same way, eliminating the inconsistencies associated with manual welding.

Speed and Efficiency: Compared to traditional arc welding methods, laser welding robot is much faster and requires less post-processing, such as grinding or cleaning.

Welding of Complex Geometries: Thanks to the robotic arm's flexibility and reach, even difficult-to-access joints can be welded with ease.

Reduced Thermal Distortion: The concentrated heat source of the laser minimizes heat-affected zones, reducing the chances of warping and preserving the integrity of adjacent components.

Using laser welding robots ensures that the assembled wardrobe frame is not only robust and long-lasting but also meets high standards of appearance and precision.

Conclusion: Integrated Automation for Quality and Efficiency

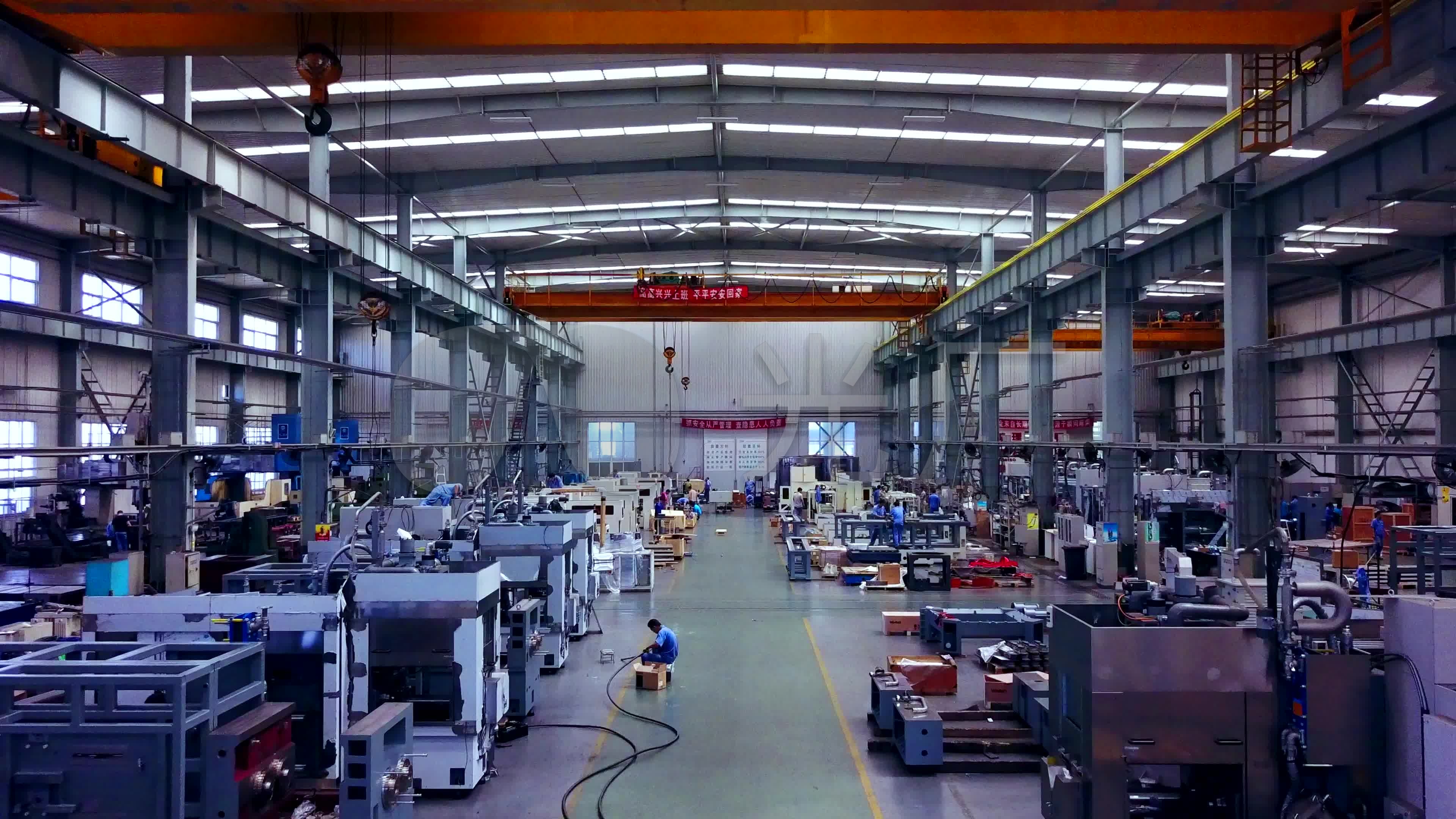

The combination of laser pipe cutting machines, pipe bending machines, and laser welding robots forms an integrated, automated workflow for manufacturing wardrobe metal frames.

As consumer expectations for both functionality and aesthetics in home furnishings continue to rise, the adoption of these advanced manufacturing technologies positions wardrobe manufacturers to stay competitive in a fast-evolving market.