Rail transit shelters are not only places for passengers to wait for transportation, but also important windows for displaying the image of the city. Laser pipe cutting machines, laser plate cutting machines, pipe bending machines and laser welding machines play a core role in the production process of rail transit shelters. They cooperate with each other to gradually transform metal materials into functional and beautiful shelters.

1. Pipe cutting - precise cutting of laser pipe cutting machines

The frame structure of rail transit shelters is mainly composed of various metal pipes, and laser pipe cutting machines play a decisive role in the pipe cutting link.

(I) Equipment advantages

High precision ensures structural safety: The cutting accuracy of laser pipe cutting machines is extremely high, and the error can usually be controlled within ±0.1mm. For shelters, accurate pipe cutting dimensions are the basis for ensuring the stability of the entire frame structure.

Efficient production meets the needs of urban construction: Compared with traditional mechanical cutting methods, laser pipe cutting machines have faster cutting speeds and significantly improved production efficiency. Laser pipe cutting machines can complete the cutting tasks of a large number of pipes in a short time, greatly shortening the production cycle.

Flexible cutting to adapt to various designs: Laser pipe cutting machines have strong flexibility and can cut pipes in various shapes such as straight lines, curves, and bevels according to the design requirements of the bus shelter. Laser pipe cutting machines can easily achieve cutting of complex shapes, providing strong technical support for the innovative design of bus shelters.

2. Plate processing - fine carving of laser plate cutting machine

Laser plate cutting machine plays an indispensable role in the plate processing link. It uses the high energy of the laser beam to quickly melt or vaporize the material on the surface of the plate, thereby achieving precise cutting.

(I) Equipment features

High-quality cutting edges improve aesthetics: The edges of the metal plates cut by the laser plate cutting machine are as smooth as a mirror, without burrs.

Complex graphics cutting realizes creative design: With the help of advanced CNC technology and powerful graphics processing software, the laser plate cutting machine has the ability to cut various complex graphics and patterns. The laser plate cutting machine can accurately realize complex designs, giving the bus shelter a unique artistic charm and cultural connotation.

Large-format cutting is suitable for large-scale component production: The laser plate cutting machine has excellent large-format cutting capabilities and can cut large-sized plate components at one time. Moreover, for metal plates of different thicknesses, the laser plate cutting machine can automatically adjust the cutting parameters according to the material characteristics and thickness of the plate to achieve stable and high-quality cutting effects.

3. pipe bending - ingenious shaping of the pipe bending machine

Some pipes need to be bent into specific angles and shapes, and the pipe bending machine demonstrates excellent shaping ability in this link.

(I) Equipment function

Accurate angle control ensures accurate shaping: The pipe bending machine is equipped with a high-precision angle control system. The precise angle control of the pipe bending machine ensures that these design requirements can be accurately achieved, making the appearance of the bus shelter more beautiful and the structure more stable.

Various bending radius options to meet design requirements: According to different design requirements, the pipe bending machine can provide a variety of bending radius options. The pipe bending machine can meet the requirements of various design ideas for pipe bending.

Stable bending quality guarantees service life: During the bending process, the pipe bending machine ensures that the bending quality of the pipe remains stable through reasonable mold design and advanced control technology.

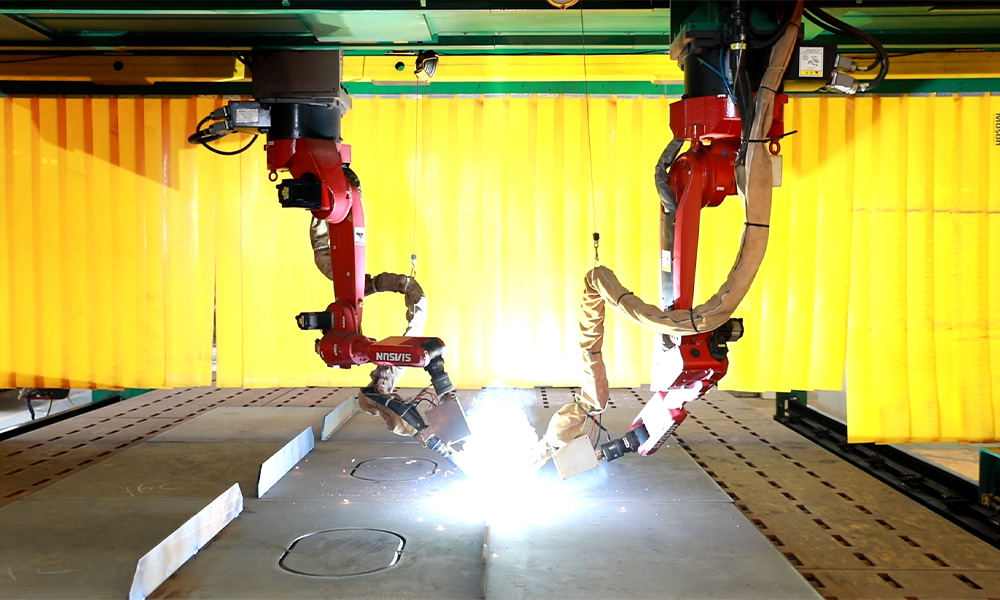

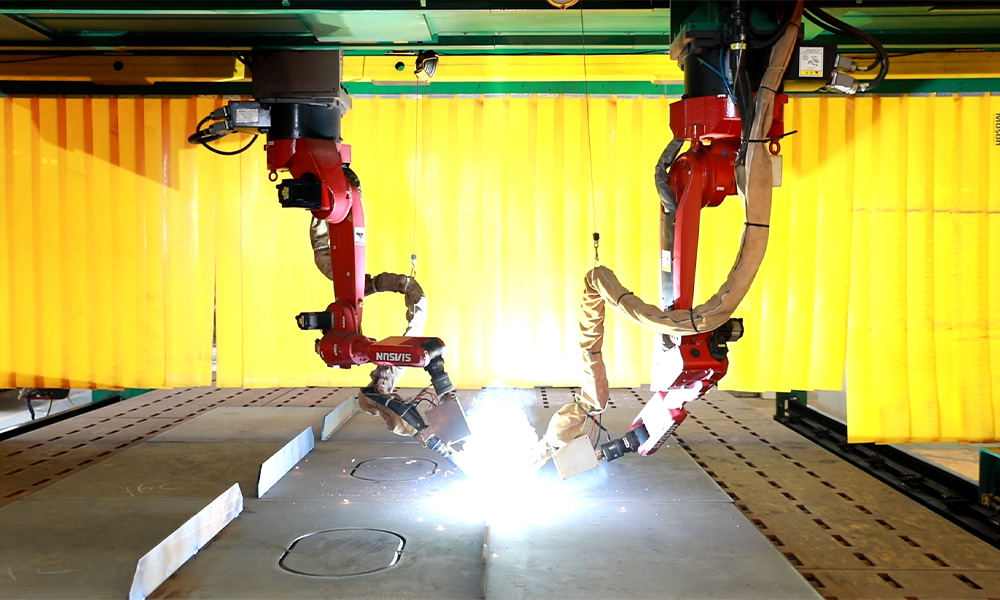

4. Component assembly and welding - the perfect integration of laser welding machines

Various pipe and plate components processed by laser pipe cutting machines, laser plate cutting machines and pipe bending machines need to be assembled into complete rail transit shelters through laser welding machine. Laser welding machines, with their significant advantages such as high energy density, high precision and low heat-affected zone, have become an ideal choice for achieving firm and beautiful connections between components.

(I) Equipment advantages

High-quality welding effects ensure structural strength: laser welding machines can achieve deep fusion welding, with deep welds and high strength, and the mechanical properties of welded joints are close to or even exceed those of the parent material.

Fast welding speed improves production efficiency: Due to the high concentration of laser energy, the welding speed of laser welding machines has been greatly improved compared to traditional welding methods. The time it takes for a laser welding machine to complete welding is only about one-third of that of traditional arc welding.

Precise welding positioning ensures assembly accuracy: laser welding machines are usually equipped with high-precision visual positioning systems and motion control systems, which can achieve precise control of welding positions.

5. Summary

From metal raw materials to the formed rail transit shelter, laser pipe cutting machine, laser plate cutting machine, pipe bending machine and laser welding machine form a precise and efficient production chain. The coordinated operation of these four major equipment not only greatly improves the production efficiency of the shelter, shortens the production cycle, but also fundamentally guarantees the product quality.