Double Exchange Fiber Laser Cutting Machine

Technical parameters

|

| Project | Parameters |

| Laser power | 13000W / 6000W / 8000W / 12000W |

| Machine tool model | 2060/ 2560 / 2580 / 25100 / 25120 |

| Processing range | 6000x2000mm / 6000x2500mm / 8000x2500mm / 10000x2500mm / 12000x2500mm |

| X / Y axis positioning accuracy | 士 0.03mm |

| X / Y axis repeated positioning accuracy | ±0.05mm |

| Maximum positioning speed | 120m/min |

| Maximum acceleration | 1.5G |

Working voltage

| 380V/50HZ |

| Power protection level | IP54 |

A double exchange fiber laser cutting machine is a type of laser cutting machine that has two worktables. This allows the operator to load and unload one workpiece while the other workpiece is being cut. This can significantly improve the cutting speed and efficiency of the machine.

The main components of a double exchange fiber laser cutting machine are:

· Two worktables: One worktable is used to load and unload the workpieces, while the other worktable is used to cut the workpieces.

· A laser source, typically a fiber laser.

· A beam delivery system, which focuses the laser beam onto the workpiece.

· A cutting head, which holds the laser beam and moves it across the workpiece.

· A CNC controller, which controls the movement of the cutting head.

· A fume extraction system, which removes smoke and fumes from the cutting process.

Double exchange fiber laser cutting machines are used to cut a variety of materials, including steel, aluminum, copper, and plastics. They are used in a variety of industries, including manufacturing, aerospace, and medical.

The advantages of double exchange fiber laser cutting machines include:

· Increased cutting speed: The ability to load and unload one workpiece while the other workpiece is being cut can significantly improve the cutting speed of the machine.

· Increased efficiency: The ability to load and unload workpieces more quickly can free up operators for other tasks, improving the efficiency of the machine.

· Reduced labor costs: The ability to automate the loading and unloading of workpieces can reduce labor costs.

· Improved accuracy: The ability to load and unload workpieces more precisely can improve the accuracy of the cuts.

The disadvantages of double exchange fiber laser cutting machines include:

· The initial cost of the machine is high.

· The machine requires regular maintenance.

· The machine can be dangerous if not operated properly.

If you are looking for a high-speed, efficient, and accurate way to cut materials, then a double exchange fiber laser cutting machine is a good option. These machines can save you time and money, and they can produce high-quality cuts that meet your requirements.

Here are some of the factors to consider when choosing a double exchange fiber laser cutting machine:

· The size of the workpiece: Make sure the machine can accommodate the size of the workpieces you need to cut.

· The thickness of the workpiece: Make sure the machine can cut the thickness of the workpieces you need to cut.

· The materials you need to cut: Make sure the machine can cut the materials you need to cut.

· The features you need: Consider the features that are important to you, such as automatic loading and unloading, fume extraction, and CNC control.

· The budget: Set a budget for the machine and stick to it.

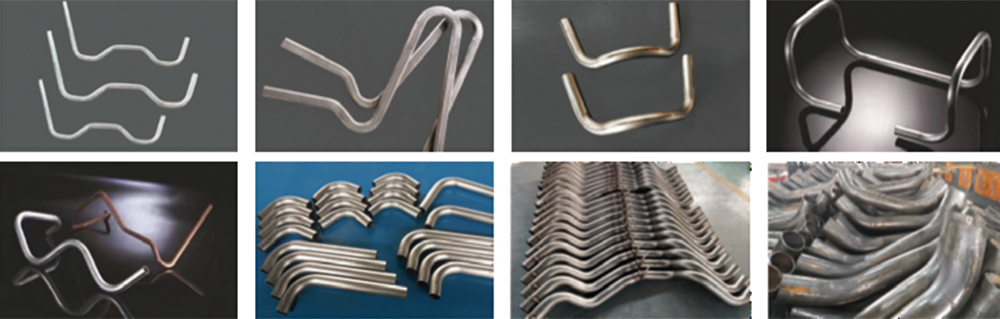

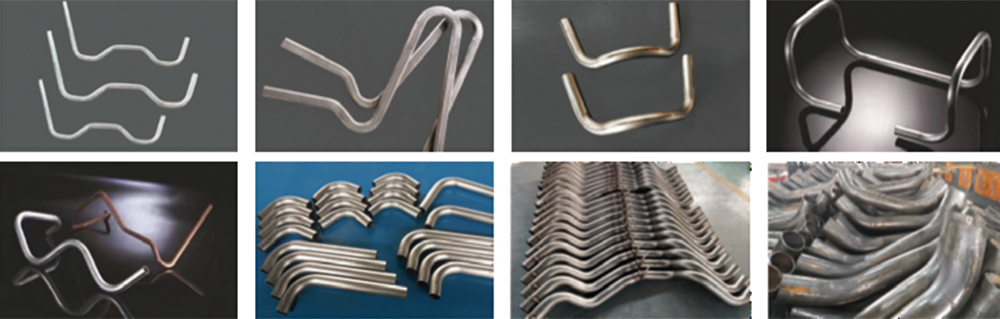

Processable pipe details

Service Support · QINGGONG Robot

Stricter quality control · Make quality better