Full Automatic Metal Circular Saw Machine

Sawing capacity

○ ≤ Φ140mm

□ ≤ 120×120mm

A full automatic metal circular saw machine is a type of metal cutting machine that uses a circular saw blade to cut through metal workpieces. The machine is equipped with a computer numerical control (CNC) system that automatically controls the cutting process. This makes the machine very accurate and efficient.

Full automatic metal circular saw machines are typically used to cut a variety of metal materials, including steel, stainless steel, aluminum, and copper. They can be used to cut a range of workpiece shapes and sizes, including bars, tubes, pipes, and plates.

The full automatic metal circular saw machine include:

Saw blade: The saw blade is the cutting tool of the machine. It is typically made of high-speed steel or carbide and is available in a variety of diameters and tooth configurations to suit different cutting applications.

Saw head: The saw head holds the saw blade and is mounted on a movable arm. The arm can be adjusted to control the cutting depth and angle.

Workpiece feed mechanism: The workpiece feed mechanism moves the workpiece through the saw blade. This is typically done using a CNC-controlled servo motor.

CNC system: The CNC system controls the entire cutting process, including the saw blade speed, feed rate, and cutting depth.

Load the workpiece into the machine and clamp it in place.

Program the CNC system with the desired cutting parameters.

Start the cutting process.

The CNC system will automatically control the cutting process, and the workpiece will be cut to the desired dimensions.

Once the cut is complete, the machine will stop automatically.

Remove the workpiece from the machine.

Full automatic metal circular saw machines offer a number of advantages :

Increased productivity: Full automatic machines can cut metal workpieces much faster than manual and semi-automatic machines.

Improved accuracy and consistency: Full automatic machines produce high-quality cuts with consistent accuracy.

Increased versatility: Full automatic machines can be used to cut a wide range of metal materials, shapes, and sizes.

Full automatic machines can be integrated into production lines, which can further improve productivity and efficiency.

Full automatic machines can be used to cut complex shapes and profiles with ease.

Full automatic machines can be used in a variety of environments, including harsh environments.

Technical parameters

|

| NAME/MODEL | 1MC-425CNC-1A left and right clamps (20° inlet miter cut) |

| Machine head rotation angle | 90° |

| Machinable material | Stainless steel, iron, copper, aluminum, plastic pipe |

| Applicable specification of saw blade | Φ350-500mm |

| Cooling and lubrication | Water-soluble anti-rust coolant |

| Main engine motor | 4kw |

| Spindle speed | Four-speed |

| Feeding mode | Hydraulic |

| Fixture | Automatic double-opening and double-closing zero-scratch, many types of pipe share fixture |

| Maximum single feeding stroke | 0-2000mm single (CNC automatic technology unlimited length multiple feeding) |

| Cut-off length setting | 0-6000mm |

| Accuracy of sawing products | ±0.3mm |

| Shortest tailings | 10-20mm |

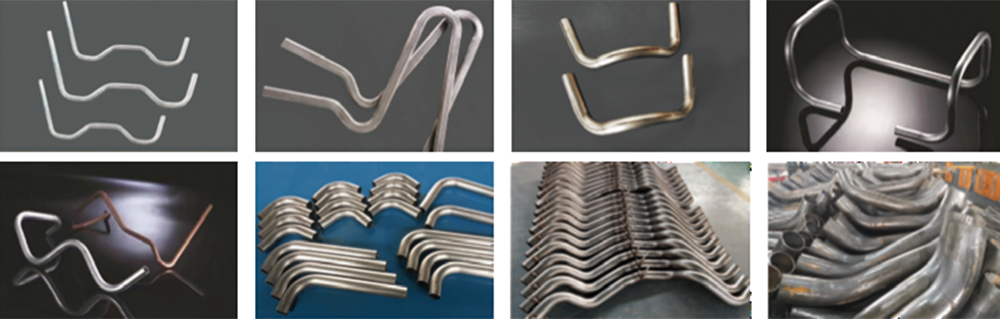

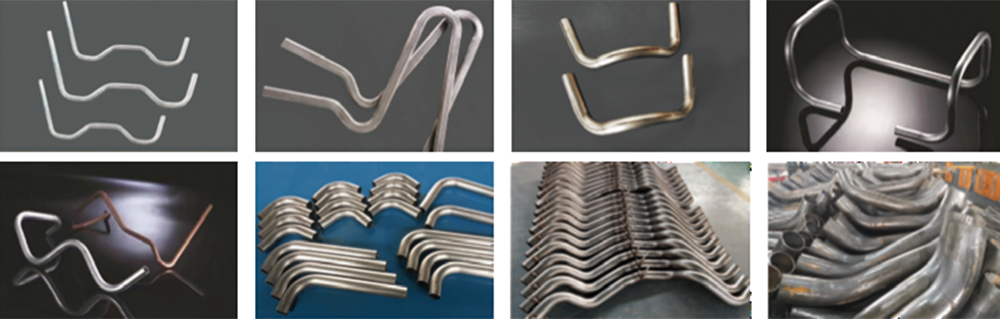

Processable pipe details

Service Support · QINGGONG Robot

Stricter quality control · Make quality better