The production of RVs is a high-precision engineering task involving multiple complex manufacturing processes and technical equipment. Among these advanced equipment, pipe bending machines, laser pipe cutting machines and laser welding machines are one of the key equipment. This article will introduce in detail the application of these three equipment in RV production and their working principles.

1. Application of pipe bending machines in the production of RV structural parts

1.1 Working principle of pipe bending machines

Pipe bending machines are equipment used to bend metal pipes at a certain angle and radius. In the manufacturing process of RVs, pipe bending machines are mainly used to make frames, brackets and piping systems.

The pipe bending machine is operated by different technical methods. The most common ones are CNC pipe bending machine and hydraulic pipe bending machine.

CNC pipe bending machine is controlled by computer program and can accurately control the bending angle and radius of the pipe; while hydraulic pipe bending machine uses hydraulic system to apply force to complete the bending of the pipe.

These technologies ensure that each pipe can maintain consistent bending angle and shape in mass production.

1.2 Application of pipe bending machine in RV frame

The role of pipe bending machine in RV frame production is particularly important. Using pipe bending machine to bend the pipe can ensure that the connection points of each part of the frame are accurate and in place, making the entire frame more solid.

In the production of some customized RVs, pipe bending machine can also bend at specific angles and curves according to design requirements. For example, the connection frame between the living area and the driving area of the RV often needs to maintain structural stability in a small space. At this time, the pipe bending machine can accurately complete complex bending tasks and avoid errors caused by manual operation.

1.3 Advantages of pipe bending machine

High precision, high production efficiency, material saving, and adaptability to a variety of materials.

2. Application of laser pipe cutting machine in the production of RV parts

2.1 Working principle of laser pipe cutting machine

Laser pipe cutting machine is a device that uses laser beam to cut tubes with high precision. The cutting process of laser pipe cutting machine is very fast and accurate, and it can cut pipes of different materials and thicknesses.

The advantages of laser pipe cutting machine are smooth cutting lines, no burrs, no deformation, and it can cut on complex-shaped pipes. It has strong adaptability and greatly improves production efficiency and precision.

2.2 Application of laser pipe cutting machine in RV parts

In the production of RVs, laser pipe cutting machines are mainly used to cut components such as frames, piping systems, and support structures. These components usually require complex shapes and precise dimensions, and laser pipe cutting machines can meet this demand.

In addition, the roof, body bracket and other components of RVs also need to be precisely cut. The laser pipe cutting machine can accurately cut each pipe according to the design drawings to ensure that the size and shape of the components are fully in line with the standards.

2.3 Advantages of laser pipe cutting machine

High precision, no burrs, no deformation, strong flexibility, and high automation.

3. Application of laser welding machine in RV structural connection

3.1 Working principle of laser welding machine

Laser welding machine is a device that uses high-energy laser beam to locally heat metal materials to the melting point and weld. In the manufacturing process of RVs, laser welding machines are mainly used for welding metal parts such as frames, brackets, chassis, etc.

The working process of laser welding machine is relatively simple: first, the laser beam is transmitted to the welding position through optical fiber, and then the laser beam locally heats the metal to the melting point, and the metal melts to form a weld. As the laser beam moves, the molten pool gradually solidifies to form a strong welded connection.

3.2 Application of laser welding machine in RV manufacturing

In the production process of RVs, the connection between the frame and various components usually needs to be completed by welding. Laser welding technology can provide higher precision and stronger connection strength than traditional welding, ensuring the stability of the body structure.

Traditional welding methods usually produce a large heat-affected zone, resulting in deformation and strength loss of components. Laser welding can achieve low heat input, high welding strength, and high precision of the welding part, which greatly reduces the subsequent adjustment and repair work.

In addition, laser welding machines can also be used to connect the interior parts of RVs, such as seat frames and lockers. These parts are usually delicate and require no obvious marks after welding, while ensuring that the structure is firm.

3.3 Advantages of laser welding machines

High precision, high strength, reduced thermal damage, fast welding speed, improved production efficiency, and time and cost savings.

4. Summary

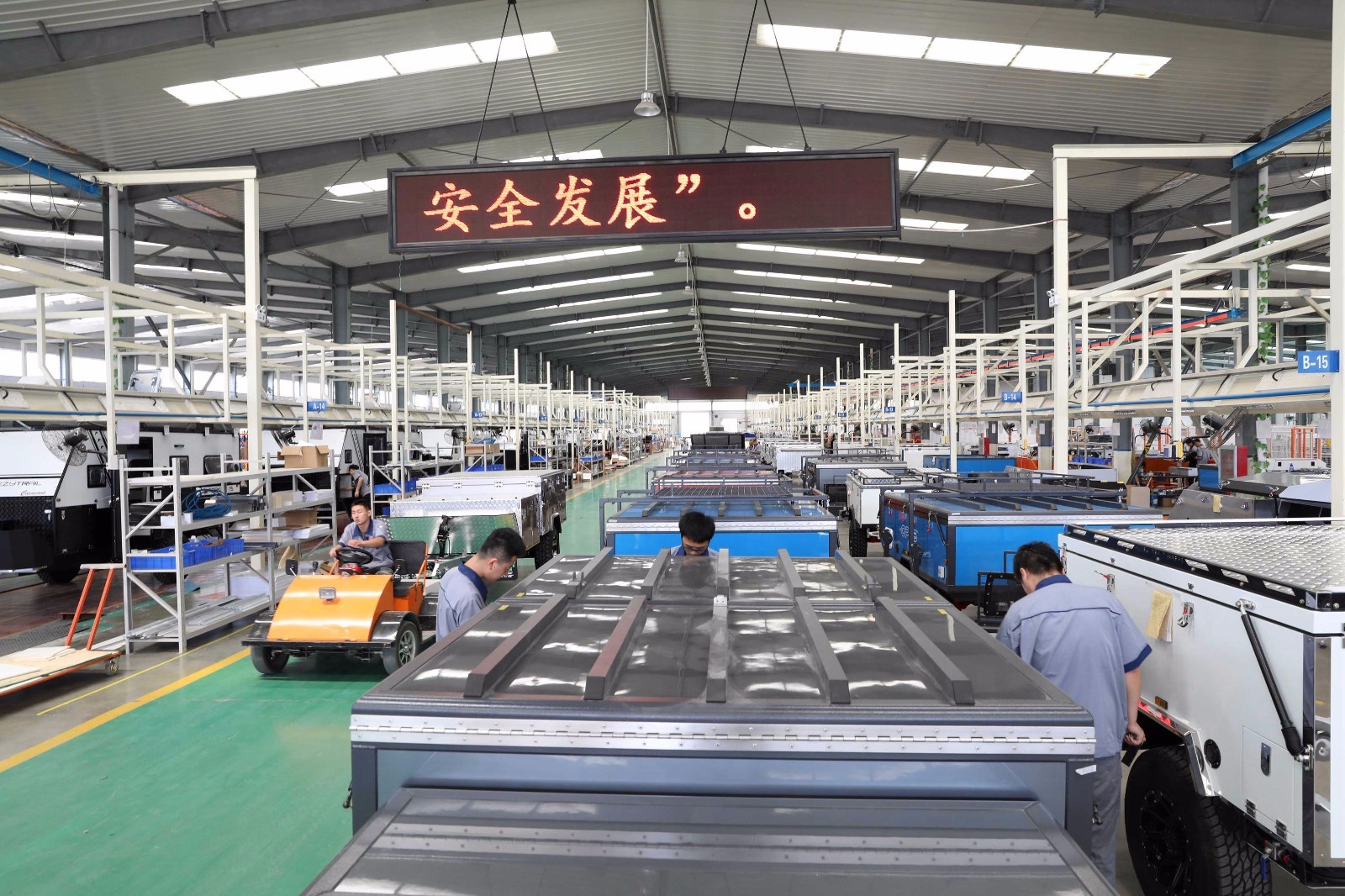

With the continuous advancement of manufacturing technology, the design and manufacturing of RVs will become more and more sophisticated, and new technologies will continue to drive the development of the industry. Through the application of these advanced equipment, the production efficiency and quality of RVs have been significantly improved, and consumers have also been provided with a more comfortable, safe and personalized travel experience.