In the field of pipe processing, laser pipe cutting machine with its high precision, high efficiency and versatility, has won a wide range of applications. However, in the face of a wide variety of laser pipe cutting machines on the market, how to choose a suitable equipment for their own needs, has become the focus of many enterprises. This paper will explain the basic working principle and advantages of laser pipe cutting machine, its types and application scenarios, and the key considerations when purchasing.

Basic working principle and advantages of laser cutting machine

Understanding the basic principles and classification of laser cutters is crucial. The laser cutting machine uses the focused high-energy laser beam to heats the material locally, so that the material quickly melt or vaporization, and at the same time, it blows the melt away through the high pressure gas, so as to achieve the purpose of cutting. This cutting method has incomparable advantages than traditional mechanical cutting.

High precision and high efficiency: laser cutting machine can be extremely fine cutting, narrow cutting seam, smooth cutting surface, without secondary processing. In addition, the laser cutting speed is fast, especially in the processing of thin plates and complex figures, which is much higher than the traditional cutting methods.

Non-contact processing: Laser cutting is non-contact processing, which means that there will not cause mechanical extrusion or damage to the material during the cutting process, especially for the processing of brittle materials and high hardness materials.

versatility: The laser cutting machine can cut a variety of materials, from metal to non-metal, from sheet to plate, to pipes and aliens, covering almost all industrial processing needs. At the same time, the laser cutting machine can also achieve drilling, carving, marking and other functions, a machine multi-purpose, greatly improve the utilization rate of equipment.

Different types of laser pipe cutting machines and their application scenarios

When selecting laser cutters, it is crucial to understand the different types of laser cutters and their applicable materials and application scenarios. The following are several major laser pipe cutting machine types and their characteristics:

High-speed 3D laser pipe cutting machine: for this pipe cutting machine, we have three different feeding frame for differentiation, automatic feeding rack,semi-automatic feeding and manual feeding.In general, this machine is suitable for cutting metal pipes with a diameter range of 10-80mm, fast reaction speed, high repetition accuracy, suitable for mass production, requires special fixture, but does not have high flexibility.

Double chuck laser pipe cutting machine: suitable for the pipe diameter is not more than 200mm, a single weight is less than 150 kg, the feeding length within 3 meters, on the basis of the two chbefore the floating support, cutting length weight is increased, can not do the whole whole, a certain length of the tail material can not be processed.

Three chuck laser pipe cutting machine: laser head with offside function, can cut the heavier longer pipe, can do the whole whole zero tail material, but need to be equipped with automatic feeding and automatic feeding machine, otherwise it is very difficult.

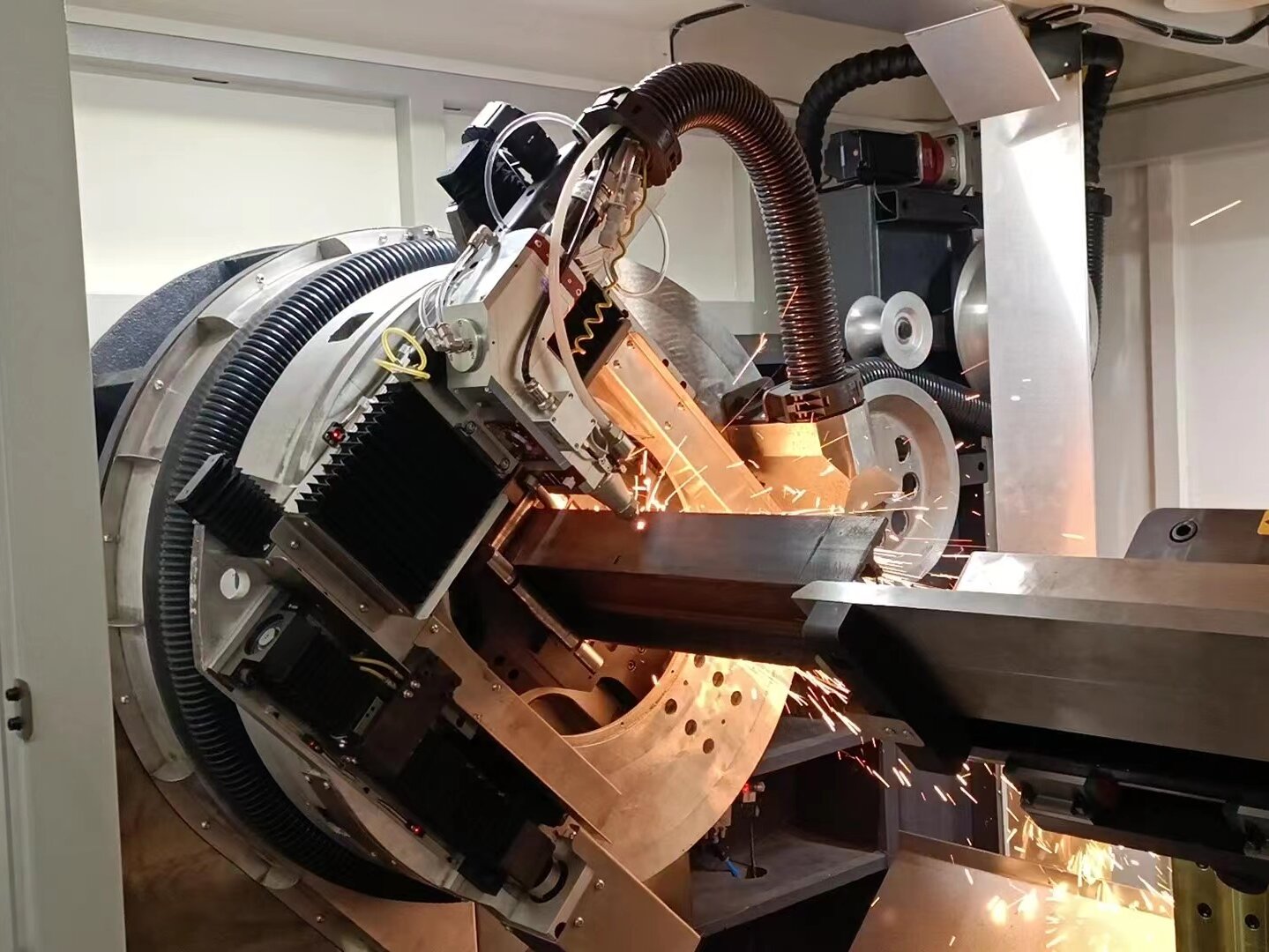

"Tornado" advanced laser pipe cutting machine: this equipment not only has high flexibility, and high efficiency, for the length and weight of the material, greatly reduce the material tremor, improve the processing efficiency and accuracy, the whole under the tail material, feeding and material is easy.

Tube and sheet integrated laser cutting machine: this equipment combines the cutting and processing of plate and pipe, with lightweight and high-precision pneumatic chuck, fast speed, small wear, high precision, can be called a perfect combination.

Key considerations for choosing laser cutters

After identifying the type of laser cutter required, the following key factors are considered to ensure that the selected equipment can fully meet the production requirements:

Cutting material and thickness: Different requirements for laser cutter for different materials.When it comes to H-shaped steel, groove steel and Angle steel, it is recommended to choose tornado series laser pipe cutting machine. This machine can be suitable for both pipe and profile, and the incision is delicate and beautiful, which is the first rotating cutting structure in the industry.

Cutting speed and accuracy: For the enterprises with high mass production and high production efficiency requirements, it is particularly important to choose the optical fiber laser pipe cutting machine with fast cutting speed and high precision. For the high-precision processing requirements, the repeated positioning accuracy and the minimum slit width of the equipment need to be considered to ensure the cutting quality.

Stability and maintenance cost of the equipment: The stability of the laser cutter is an important guarantee to ensure the long-term continuous production. In addition, the maintenance cost of equipment is an important factor to concern.

Convenience of operation and automation: When purchasing, we should consider the operation convenience of the equipment, and choose the equipment that can not only meet the production needs, but also is easy to operate and maintain. In addition, although the initial investment of the equipment with a high degree of automation is large, it can greatly reduce labor costs and improve production efficiency in the long run.

After-sales service and technical support: In this respect, our company has suppliers with perfect after-sales service system, which can get timely maintenance and technical support in case of equipment failure, to avoid long production interruption. In addition, we will provide corresponding training services, which can help operators to quickly master the use and maintenance skills of the equipment to ensure the stable operation of the equipment.

conclusion

When purchasing a laser cutting machine, different aspects should be considered.Only to buy a laser pipe cutting machine suitable for their own production needs, in order to give full play to its advantages, improve production efficiency, reduce production costs, to achieve high-quality processing effect.