Menu

- Home

- Products

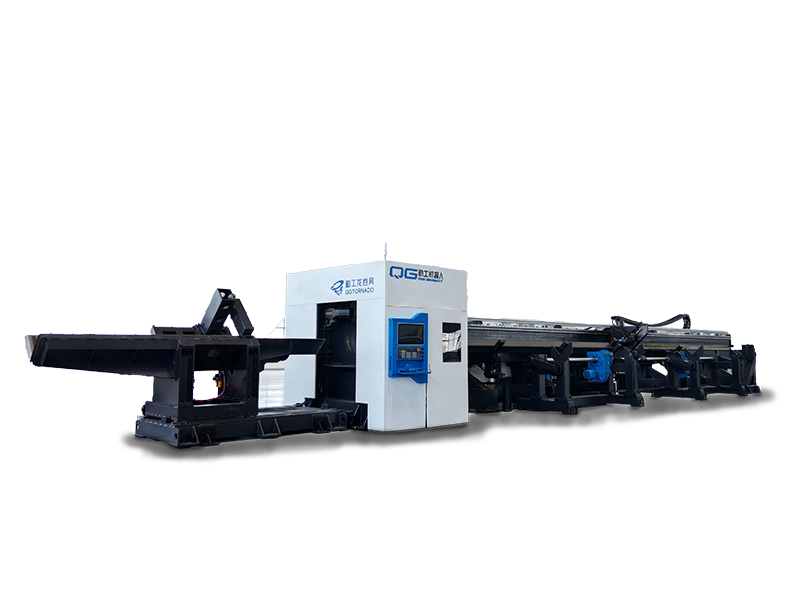

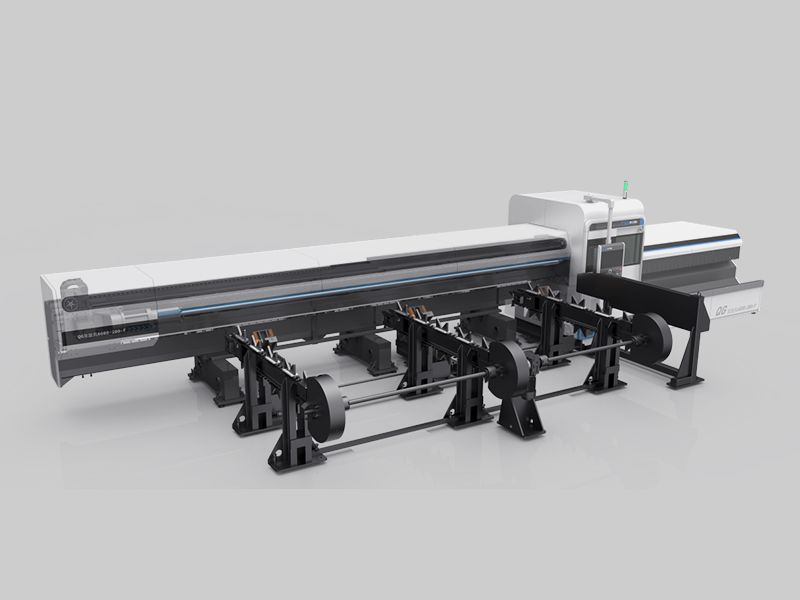

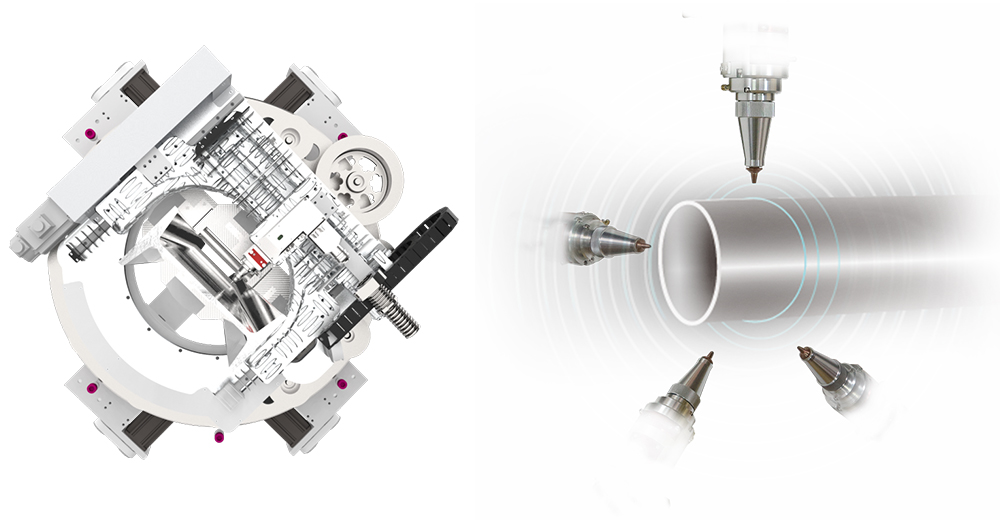

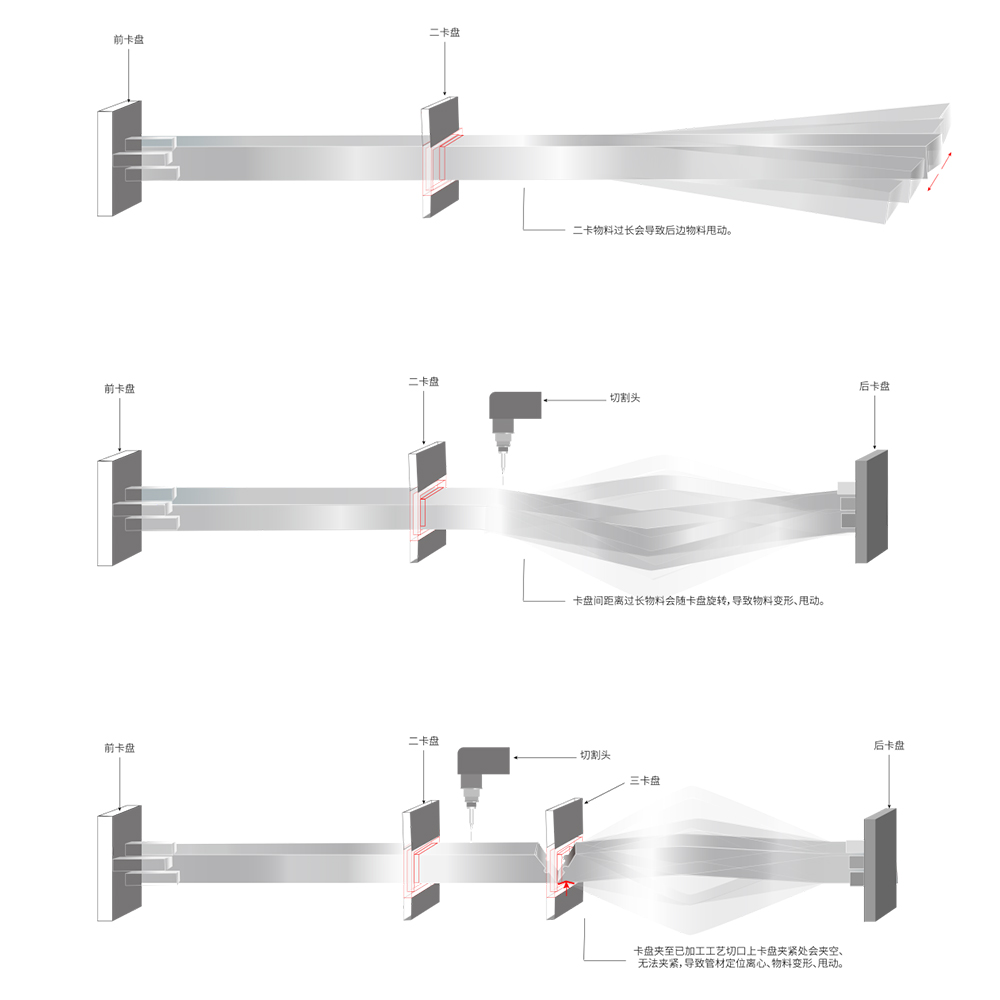

- Pipe And Sheet Cutting Machine

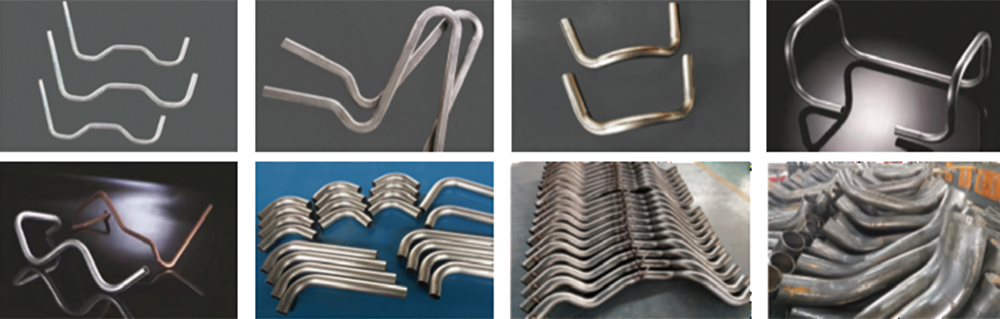

- Pipe Bending Machine

- Laser Welding Machine

- Automatic Welding Robot

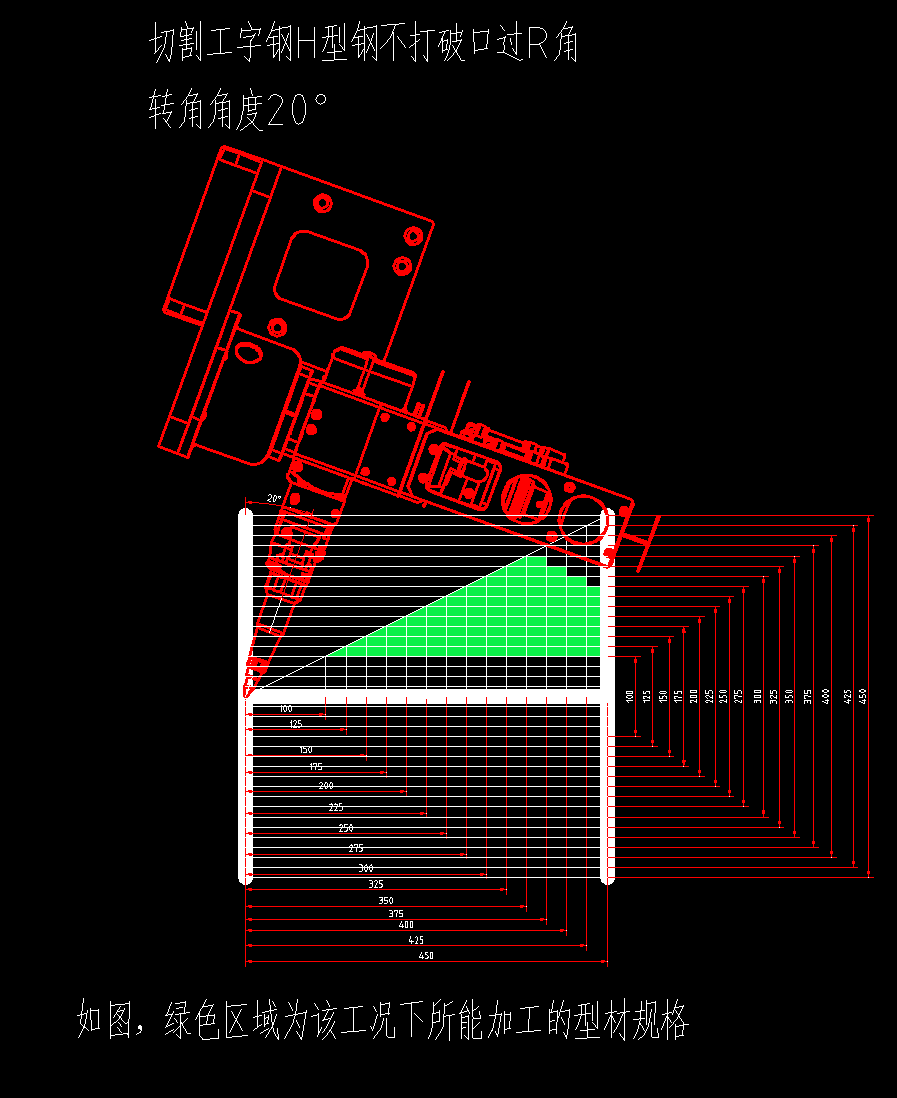

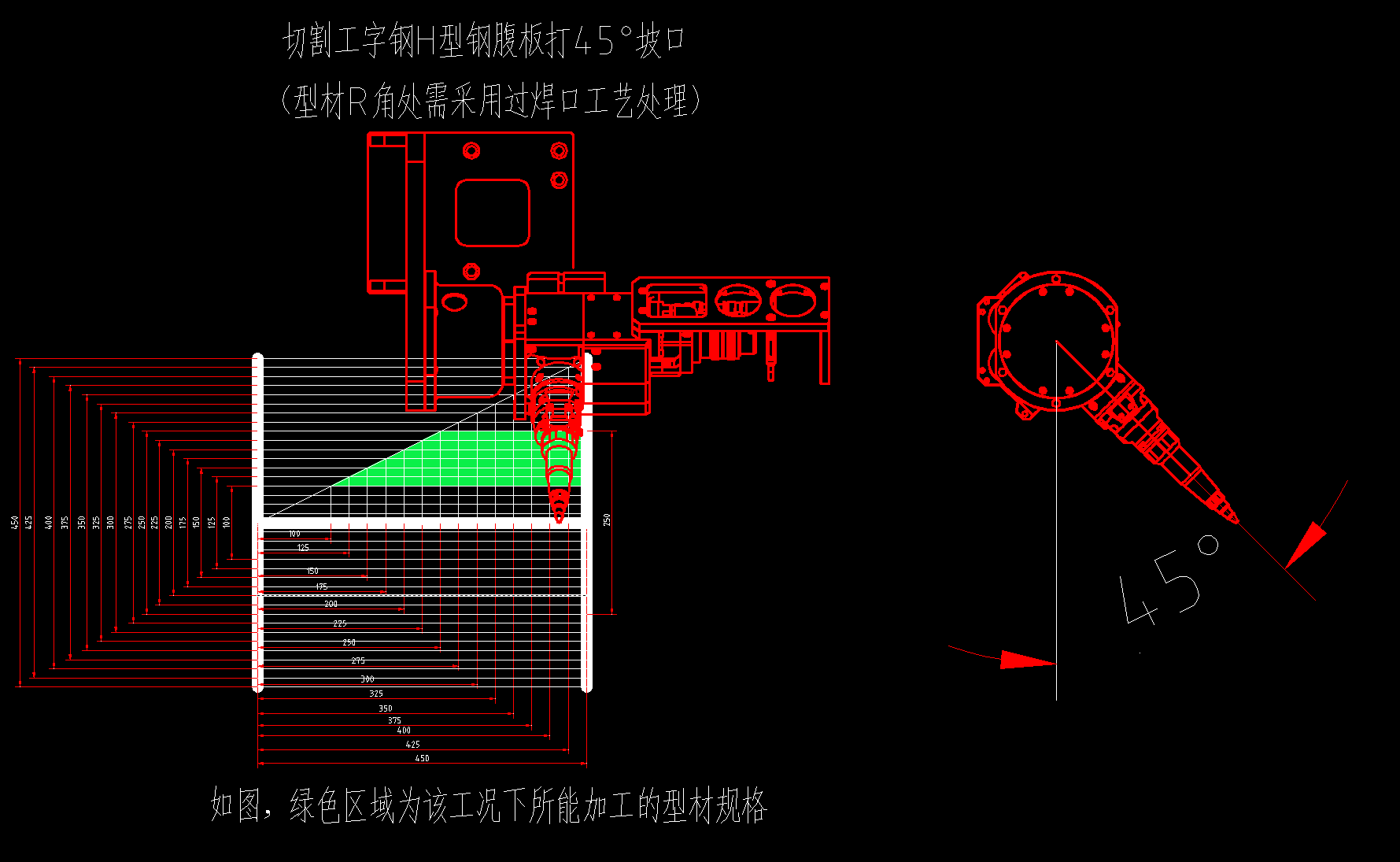

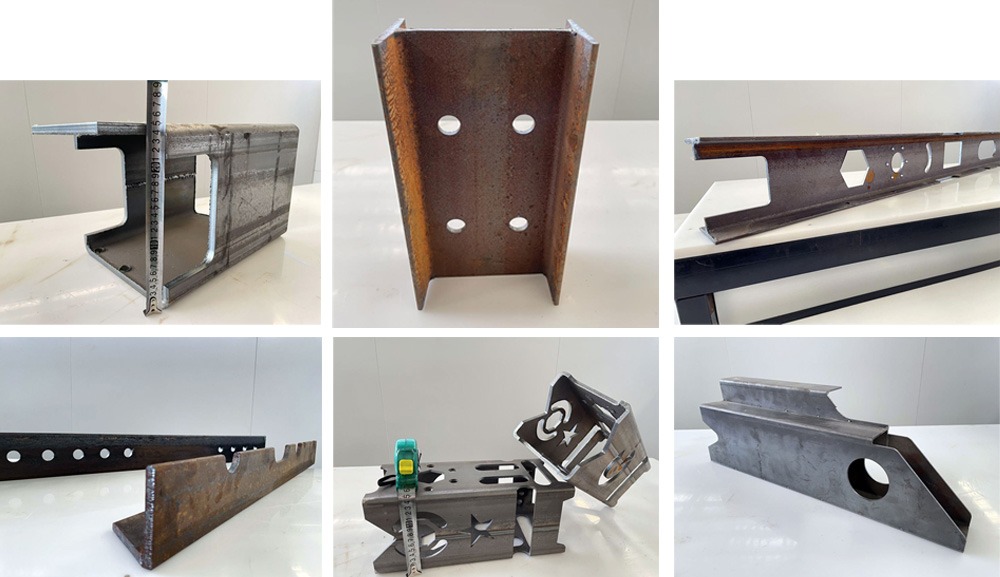

- Laser Cutting Robot

- Metal Circular Sawing Machine

- Punching And Cutting Machine

- Pipe End Forming Machine

- Pipe Tapering Machine

- News

- Company news

- Industry news

- Case

- Factory Show

- Office Environment and Factory Scale

- Laser cutting machine equipment

- Corporate history

- Contact Us

- About Us

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Video

- LASER CUTTING MACHINE

- LASER WELDING MACHINES

- PIPE BENDING MACHINES

- LASER CUTTING ROBOTS

Search