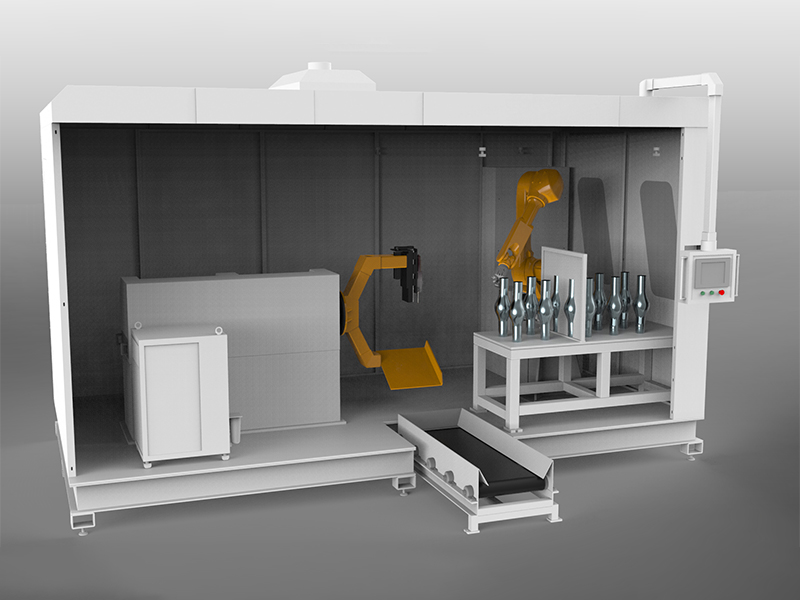

Features of exhaust pipe laser cutting machine QG-JGX-1725-A:

Using CO2 laser, cutting speed is fast and precision is high.

Can cut exhaust pipes of various materials.

The workbench is large in size and can process large exhaust pipes.

High degree of intelligence and simple operation.

Exhaust pipe laser cutting machine QG-JGX-1725-A is used in precision processing and production line automation transformation in aerospace, warships, engineering machinery, rail transit, automobiles and new energy vehicles, motorcycles, battery processing and other fields.

QG-JGX-1725-A is an exhaust pipe laser cutting machine with superior performance that can meet the cutting needs of automobile manufacturing and other industries.

Advantages of exhaust pipe laser cutting machine QG-JGX-1725-A:

Fast cutting speed: Using CO2 laser, the cutting speed can reach 20m/s, which can greatly improve production efficiency.

High precision: Using a digital bus communication module, the laser energy control is more precise, and the cutting accuracy can reach ±0.1mm.

Wide range of applications: It can cut exhaust pipes made of various materials, including stainless steel, aluminum alloy, carbon steel, etc.

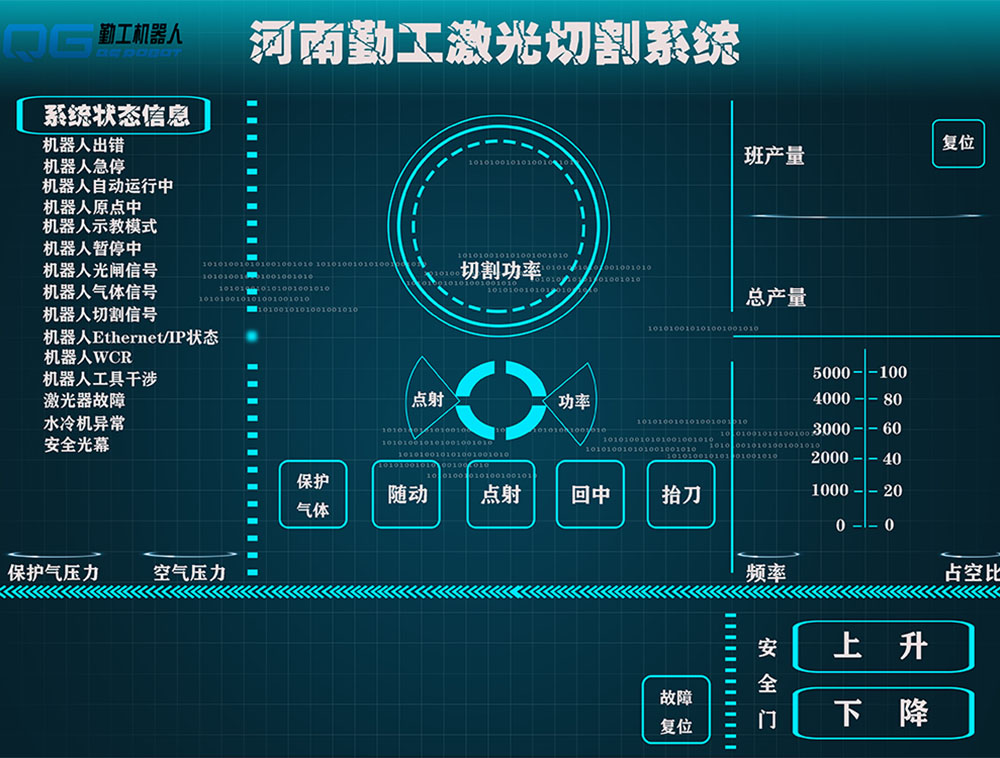

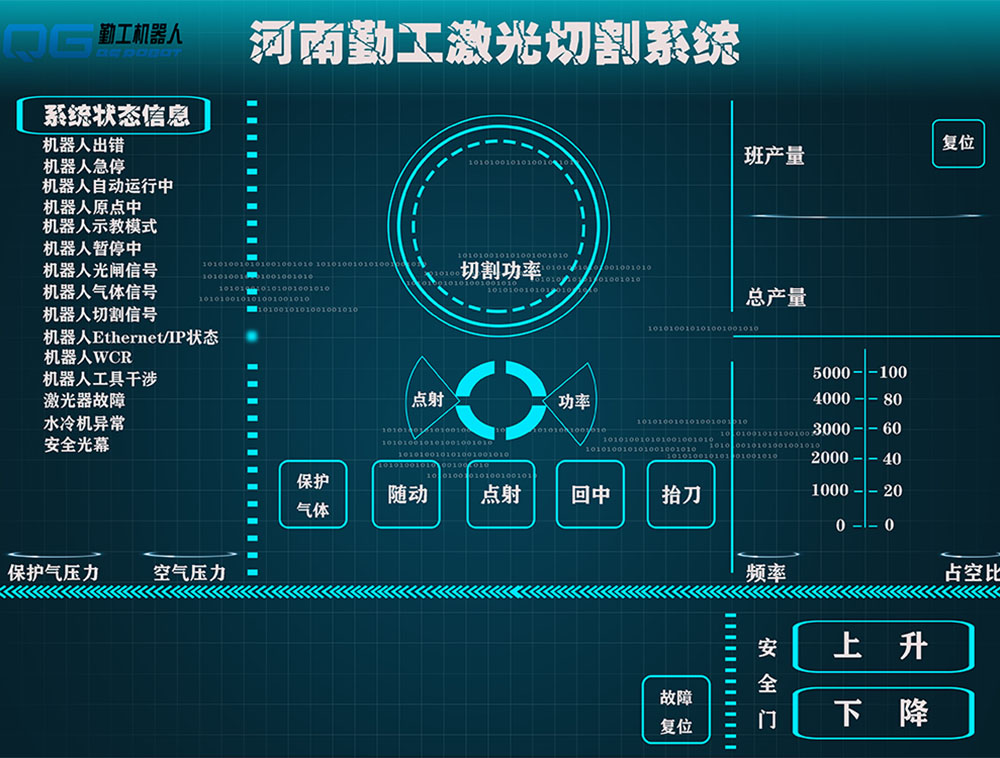

Simple operation: Using a highly intelligent HMI host control interface, the operation is simple and easy to learn.

Exhaust pipe laser cutting machine QG-JGX-1725-A Features (features common to the entire 3D laser cutting section)

1. Comes with a cutting graphics software package to make cutting processing quick and convenient.

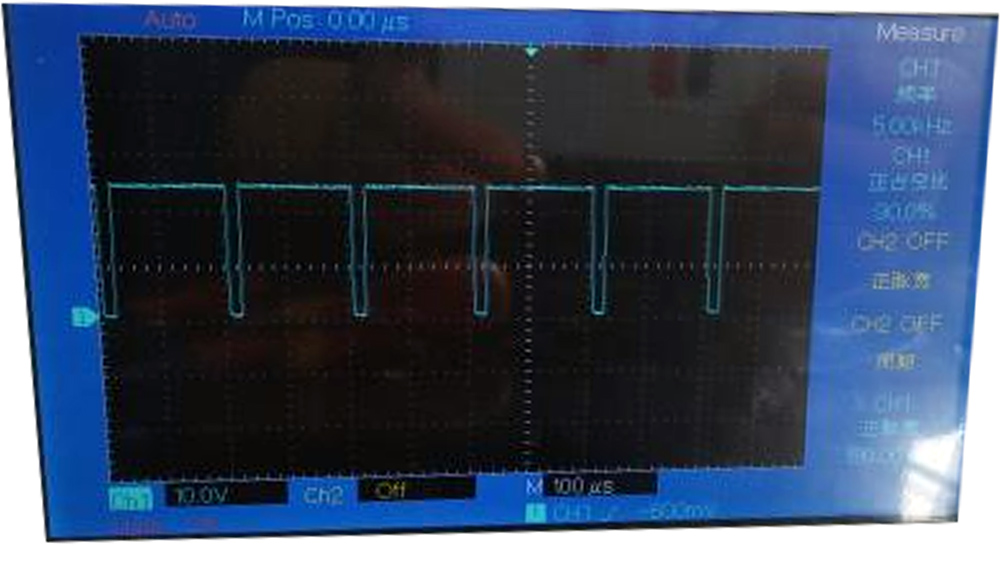

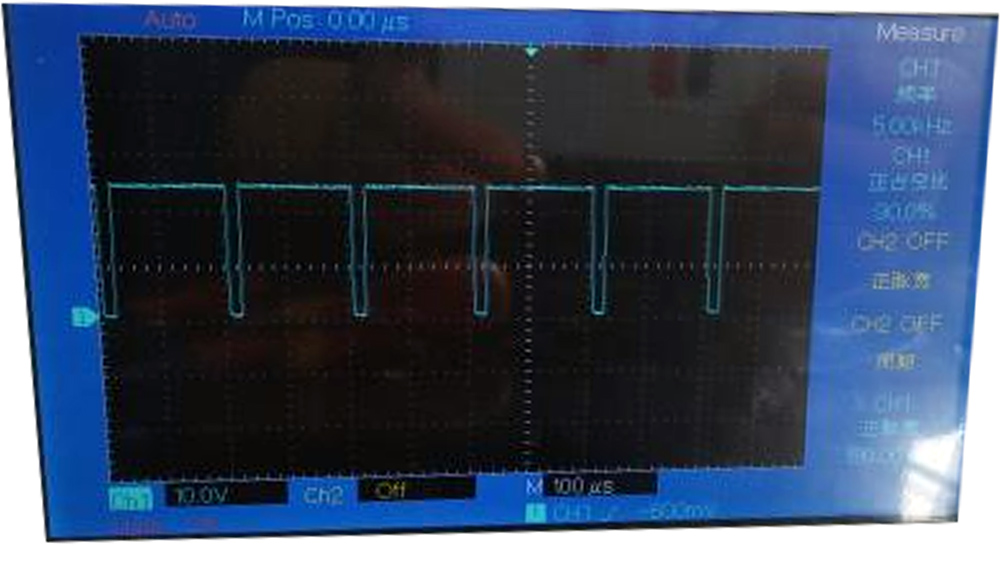

2. The digital bus communication module enables more precise control of laser energy.

(Actual status of laser energy control detection)

3. The highly intelligent HMI host control interface makes the application operation of the equipment more convenient, and the real-time equipment auxiliary inspection reminder function makes the equipment use prepared.

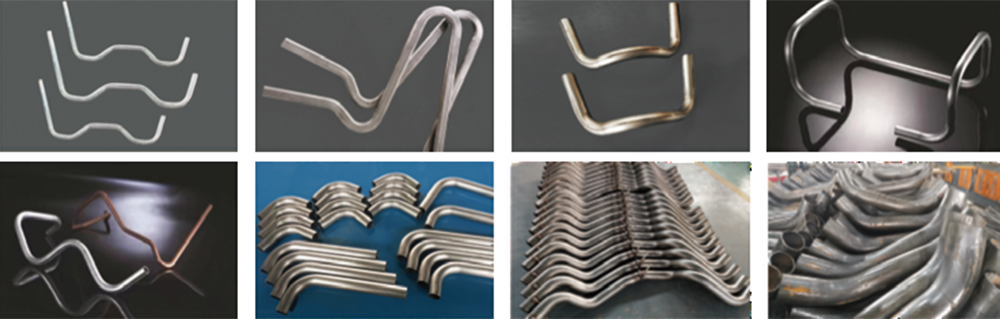

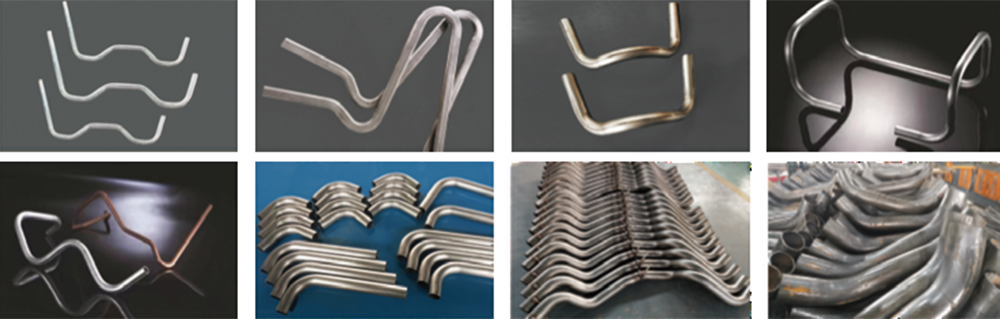

4. Highly flexible positioning, tried with a variety of special-shaped pipe products.

Application case pictures:

Technical parameters:

| Project | Parameters |

| Processing base material length | 450mm |

| Processing base material diameter | 260mm |

| Single tube load-bearing | 10KG/30KG (optional) |

| Power range | 1000W-3000W |

| Repeat positioning accuracy | ±0.1mm |

| Rotation speed | 34 R/Min |

Cutting sample display :

Processable pipe details:

Service Support · QINGGONG Robot:

Stricter quality control · Make quality better