Introduction: The importance of pipe bending machines

In modern manufacturing, pipe bending machines have become one of the indispensable equipment with their efficient and precise processing capabilities. It not only improves production efficiency, but also provides guarantee for product quality in various industries. With the continuous development of manufacturing technology, the application fields of pipe bending machines are also expanding, and they play a key role in many industries from automobiles, aviation to construction.

1. Improving production efficiency: technical advantages of pipe bending machines

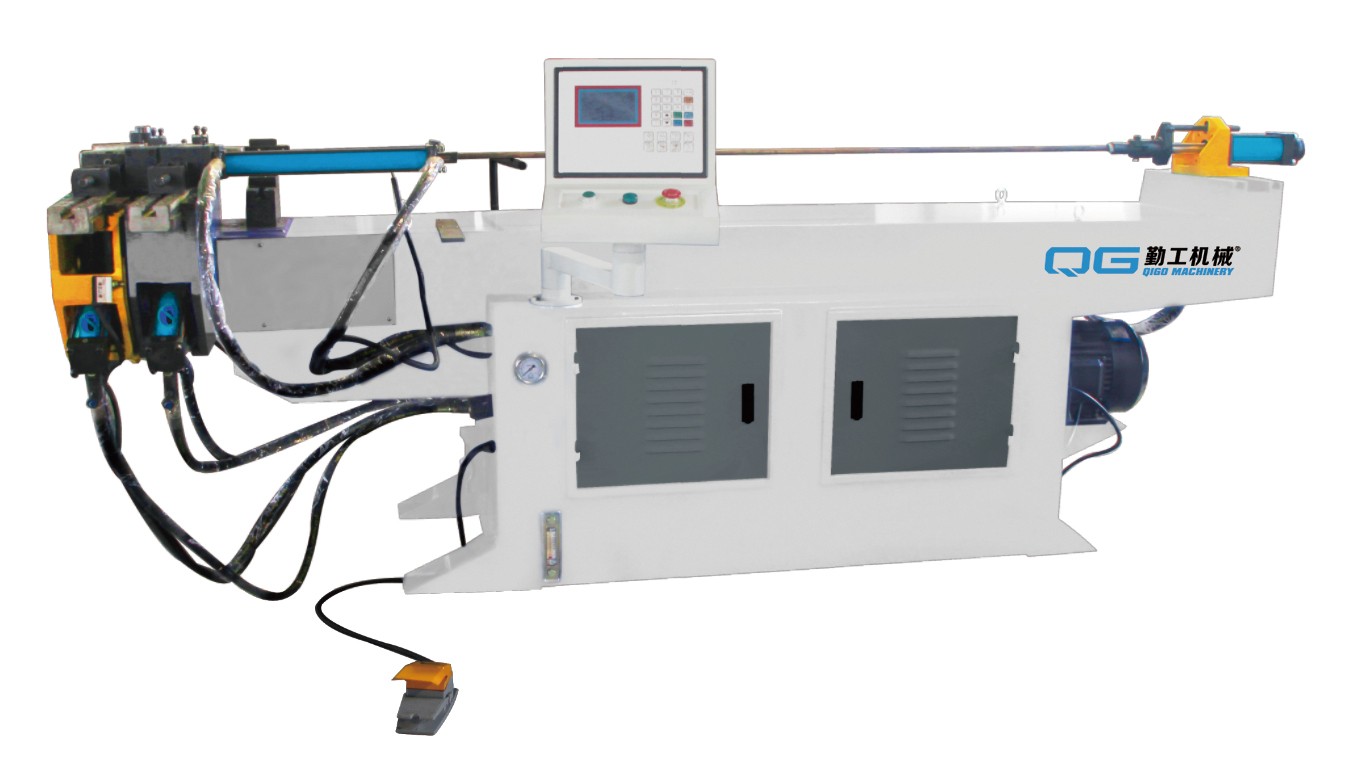

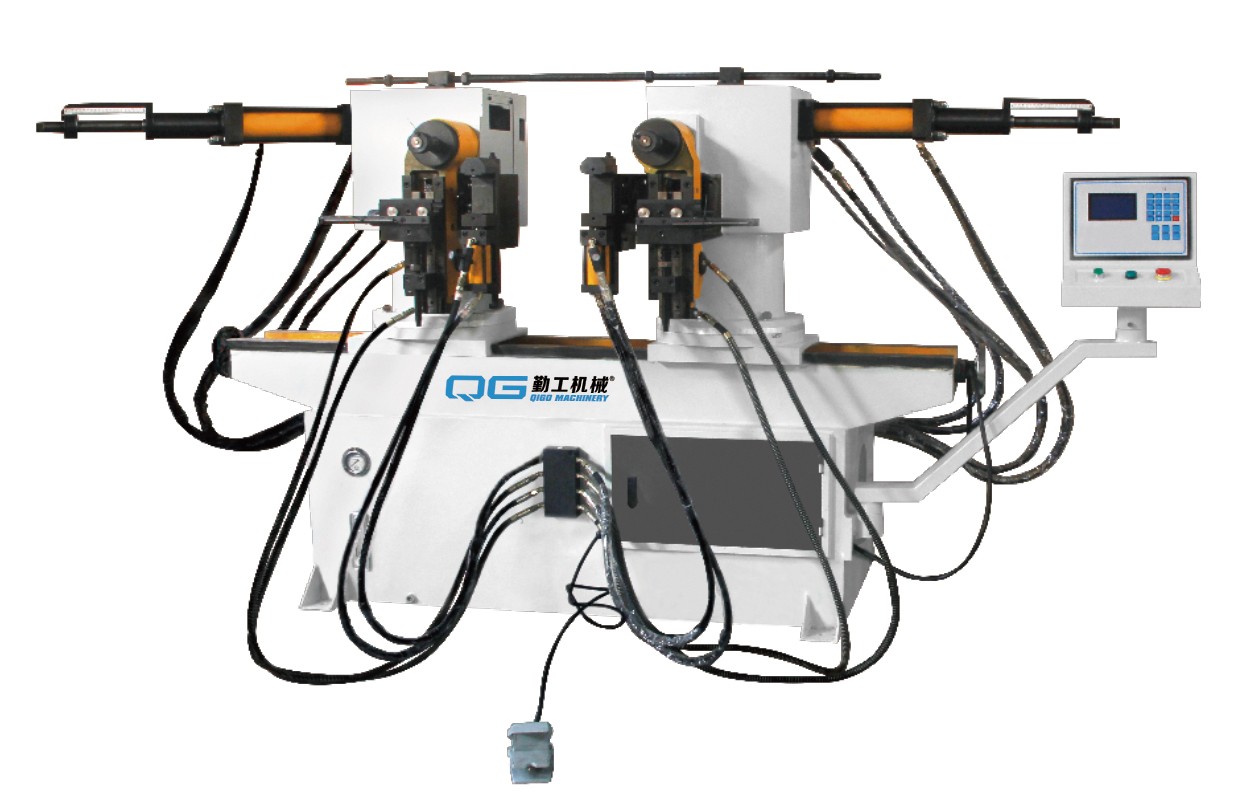

The technological progress of pipe bending machines has made them play an increasingly important role in the manufacturing industry. In addition to traditional manual pipe bending machines, there are now semi-automatic pipe bending machines and fully automatic pipe bending machines, which are convenient for selection for different needs.

Modern pipe bending machines usually use CNC technology to achieve highly automated production. Modern CNC pipe bending machines can complete complex bending tasks in a very short time. Its precise calculation and operation capabilities not only reduce material waste, but also improve the quality of finished products. For example, in automobile manufacturing, pipe bending machines can accurately control each bending angle to ensure the perfect fit of parts and ensure the overall performance of the car.

In addition, the versatility of the pipe bending machine also enables it to adapt to different types of pipes and specifications, greatly improving the flexibility of production. Whether it is small-batch production or large-scale manufacturing, the pipe bending machine can easily cope with it and meet the diverse needs of the market.

2. Quality assurance: precision manufacturing of pipe bending machines

In the manufacturing industry, product quality is an important manifestation of corporate competitiveness. The precision manufacturing capability of the pipe bending machine directly affects the quality of the final product. Through advanced control systems, the pipe bending machine can achieve high-precision bending to ensure that every product meets the design requirements.

Take the automotive industry as an example. The structure of the car is complex and the safety requirements are extremely high. The pipe bending machine can ensure the strength and durability of each pipe fitting during the production process, reducing the safety hazards caused by material defects. At the same time, the high-precision characteristics of the pipe bending machine also mean less rework and scrap rate, saving the company's costs.

In addition, the consistency of the pipe bending machine in pipe fitting processing is also a major advantage. No matter how many pipe fittings are produced, the bending accuracy and shape of each pipe fitting can be kept consistent. This consistency not only improves production efficiency, but also enhances brand reputation, making the company invincible in the competition.

3. Industry application: Wide use of pipe bending machines in various industries

The application range of pipe bending machines is very wide, covering multiple industries. The automobile manufacturing, aerospace, construction, pharmaceutical and other industries all have extremely high demands for pipe bending machines. Each industry has different requirements for pipe bending machines, and the technological advances of pipe bending machines just meet these needs.

In the field of automobile manufacturing, pipe bending machines are used to produce key components such as automobile exhaust systems and body frames. Its efficient processing capabilities and precise bending control enable automobile manufacturers to produce high-quality parts in a short time, thereby shortening the overall production cycle.

In the aerospace industry, pipe bending machines are used to manufacture aircraft structural components and piping systems. These components usually require extremely high strength and light weight, and the precision technology of pipe bending machines can meet these stringent requirements. In addition, the aerospace industry has extremely high requirements for product reliability, and the consistency of pipe bending machines in the manufacturing process ensures the quality and performance of each component.

The construction industry also relies on pipe bending machines to process various pipes and structural parts. With the diversification of architectural design, the flexibility and adaptability of pipe bending machines provide the construction industry with more design options, enabling complex building structures to be realized.

Conclusion: Future Outlook

Pipe bending machines play an indispensable role in the manufacturing industry, and their technological advancement and diversified applications will further promote the development of various industries. With the rise of intelligent manufacturing, pipe bending machines will also develop towards higher automation and intelligence, bringing more possibilities to the manufacturing industry.