01-13/2025

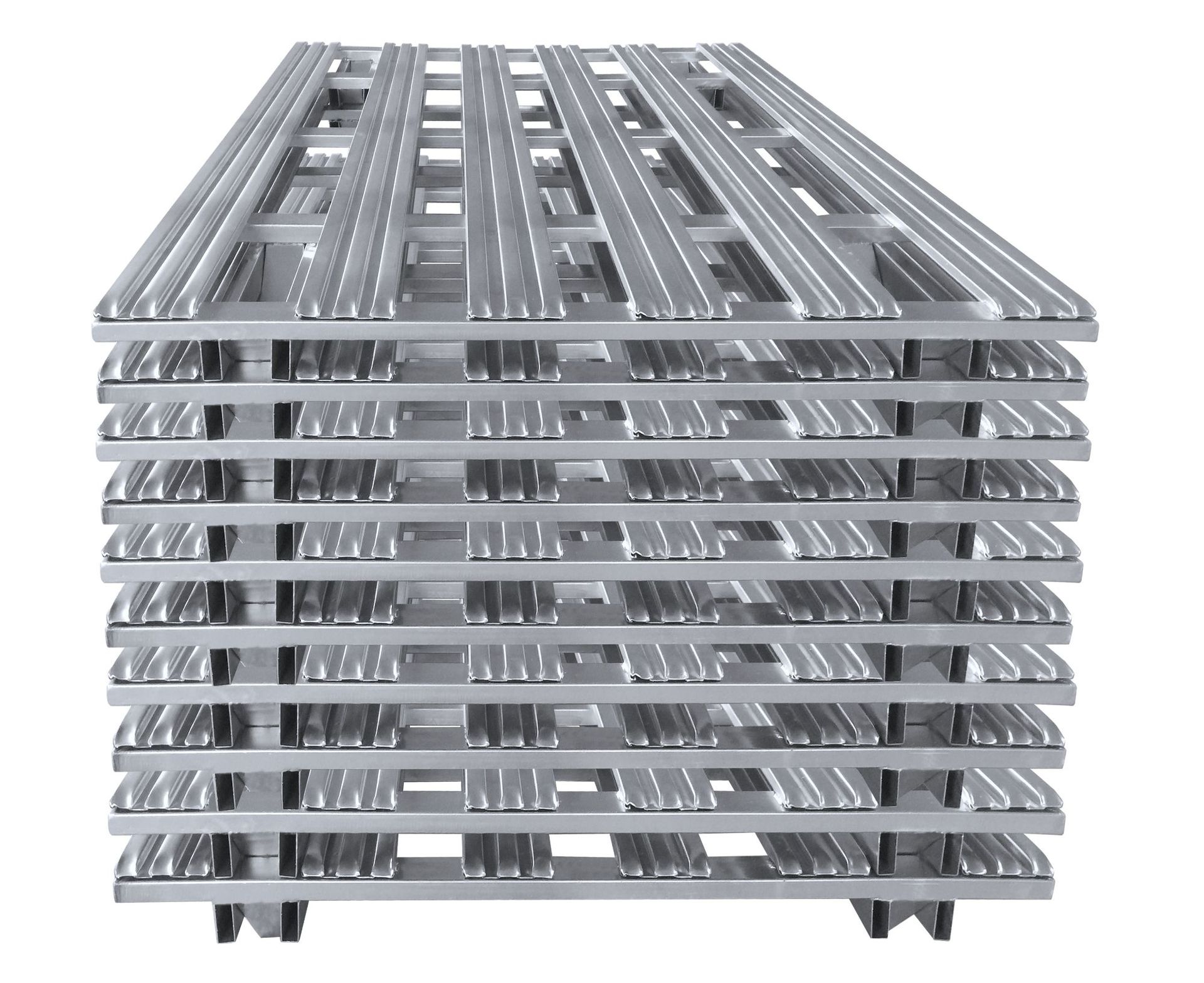

As an indispensable tool in industrial manufacturing, metal pallets are widely used in various production lines, logistics warehousing and other fields. Its durability and strong load-bearing capacity make it an ideal choice for heavy-duty handling and storage. The process of making metal pallets involves multiple steps, among which the use of advanced equipment such as laser cutting machines, bending machines and laser welding machines has greatly improved production efficiency and product quality.